AMPOWER Academy

3D Printing

Training

Interactive and hands-on 3D Printing trainings

brought to you in person by Additive Manufacturing experts

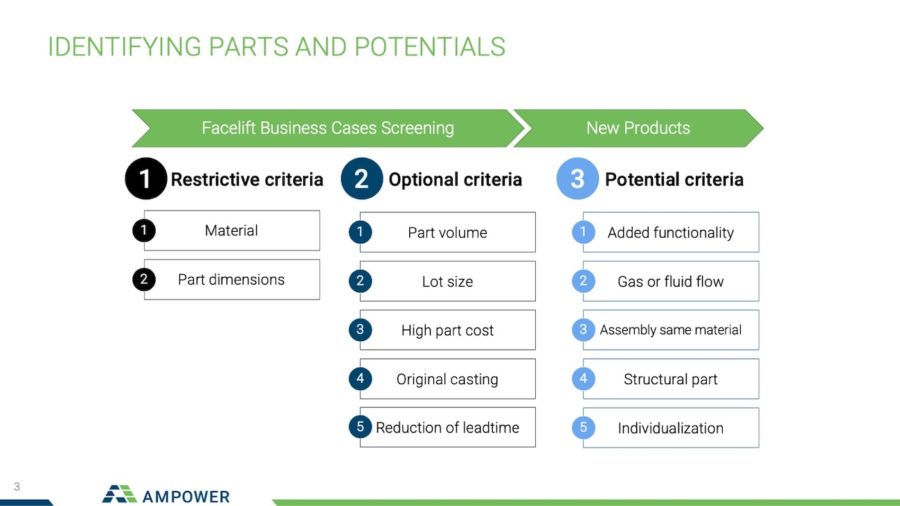

AMPOWER offers a comprehensive portfolio of 3D Printing training programs that are held by experts and seamlessly build on top of the online learning programs. For a successful implementation of 3D Printing we qualify your team along the entire process chain from business development through procurement and design to machine operation and quality assurance. In addition to the trainings outlined below, AMPOWER also offers screening for your 3D Printing applications. Find out more about AMPOWER.

3D Printing Trainings for professionals

From 3D Printing Training BASIC to PILOT PROJECT

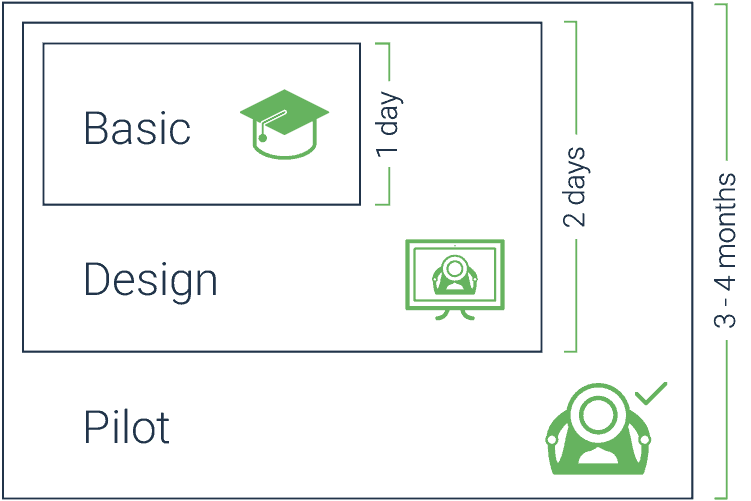

Basic

The BASIC training provides a deep dive into the technology, from understanding the process and material properties to the process chain and design guidelines. It builds upon the online learning courses and offers participants the possibility to discuss questions and dive deeper into selected topics.

Design

The DESIGN workshop consists of the BASIC module and a subsequent design workshop. Its aim is to transfer selected customer components from screening into additive concepts. The result are 3D printing concepts.

Pilot Project

The PILOT PROJECT includes the BASIC training, an internal screening for 3D Printing and the DESIGN workshop. Subsequently, a selected design is transferred to CAD data, printed and post processed to the finished part. A detailed final report rounds off the PILOT PROJECT.

500

engineers have already been trained by the trainers

100%

of the participants rate the training as good or very good

25

years of experience of the trainers in Additive Manufacturing

3D Printing Training References

What our customers say about our 3D Printing training

Additive Manufacturing Specialist, BOBST

3D Printing Training Packages

Overview of our 3D Printing training programs

The 3D Printing trainings and workshops can be carried out at your location or at our facility in Hamburg. Selected modules can be delivered online. Prices for the 3D Printing trainings are excluding VAT and travel expenses. Costs for the production of components are not included. The exact training content can be adjusted based on your goals and the prior knowledge of participants. All live trainings can be combined with the online learning programs. Get an overview of how to access to our online learning programs here.

Individual

Fundamentals

Design guidelines

Process chain

Material characteristics

Own participant parts

Creative workshop

Design concept

CAD design

Final report

Prototype produced

Total duration

Participants

Result

BASIC

DESIGN

PILOT PROJECT

3D Printing Training BASIC to teach the fundamentals

Our BASIC training aims to educate engineers and technical staff. The imparted knowledge builds upon the basics of the technology trained in the Online Learning modules, but also the material properties and design guidelines. The training documents serve as a reference work for design engineers and other engineers in the company. The lessons learned from our 3D Printing training are based on more than 10 years of experience in 3D Printing.

3D Printing training DESIGN to evaluate and discuss your parts

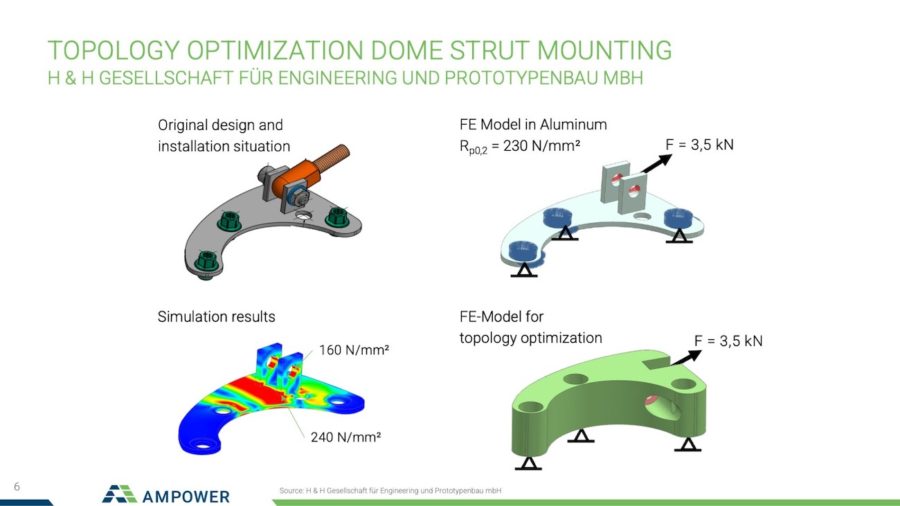

The DESIGN training builds on the BASIC Training. The basis is customer components, which were previously selected by the participants. In a first step, the requirements of the components are defined. Subsequently, creative methods are applied to develop solution concepts for 3D Printing. These lead to a design concept, which is subsequently evaluated. In the final step, the complete production process chain for 3D Printing is set up and the costs for the newly developed concept are estimated.

The 3D Printing training PILOT PROJECT as the complete package

The PILOT PROJECT builds on the BASIC Training and the DESIGN Workshop. Following the training of the fundamentals of 3D Printing, the participants’ own components will be further developed into concepts for additive manufacturing. In the PILOT PROJECT, these components are then converted into a CAD design and the data is created for production. This component is manufactured as a prototype and accompanied by the process chain to the ready-to-install component or to the complete assembly. The PILOT PROJECT results will be summarized in a final report and presented to the company management together with the project team.

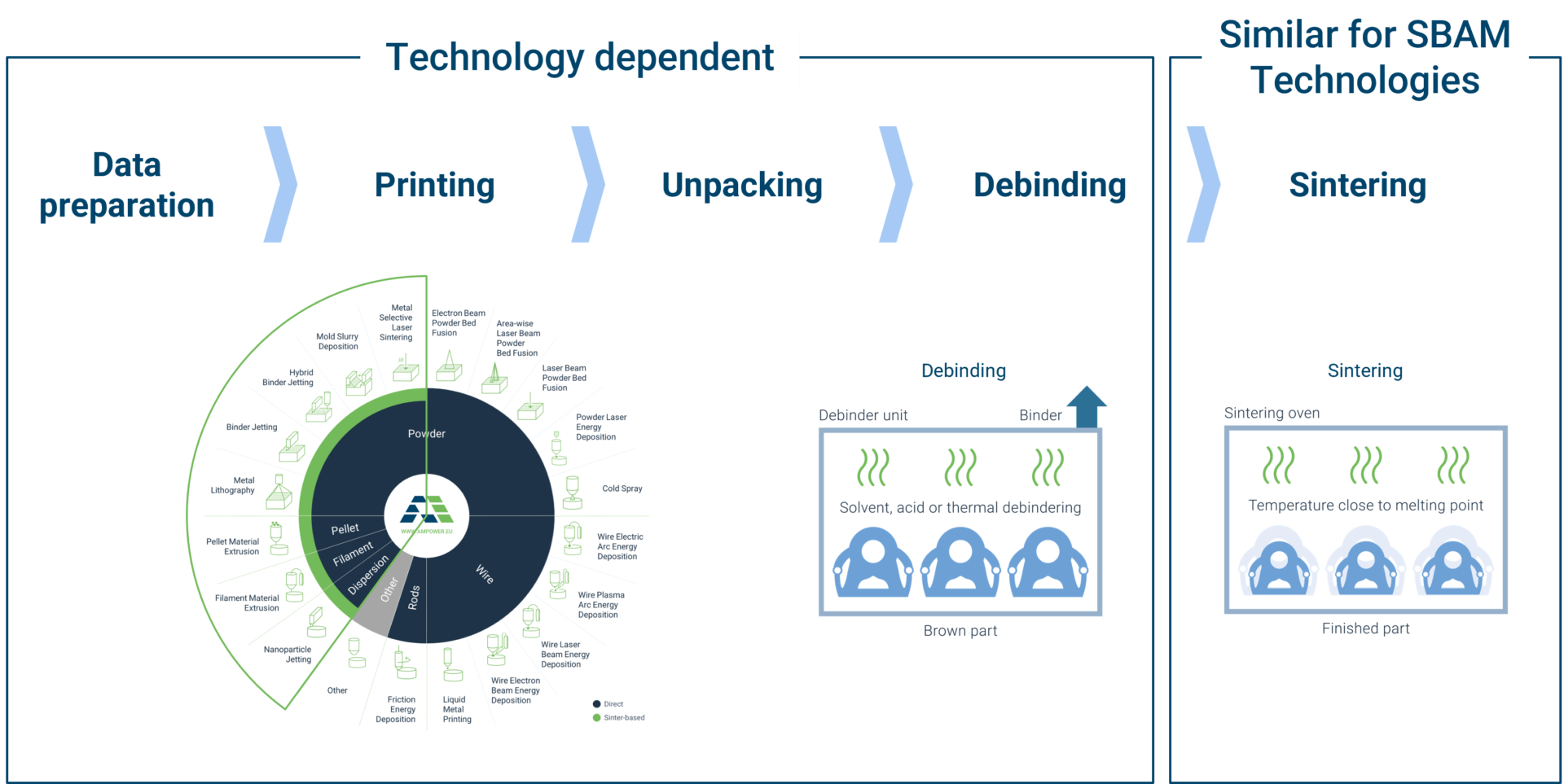

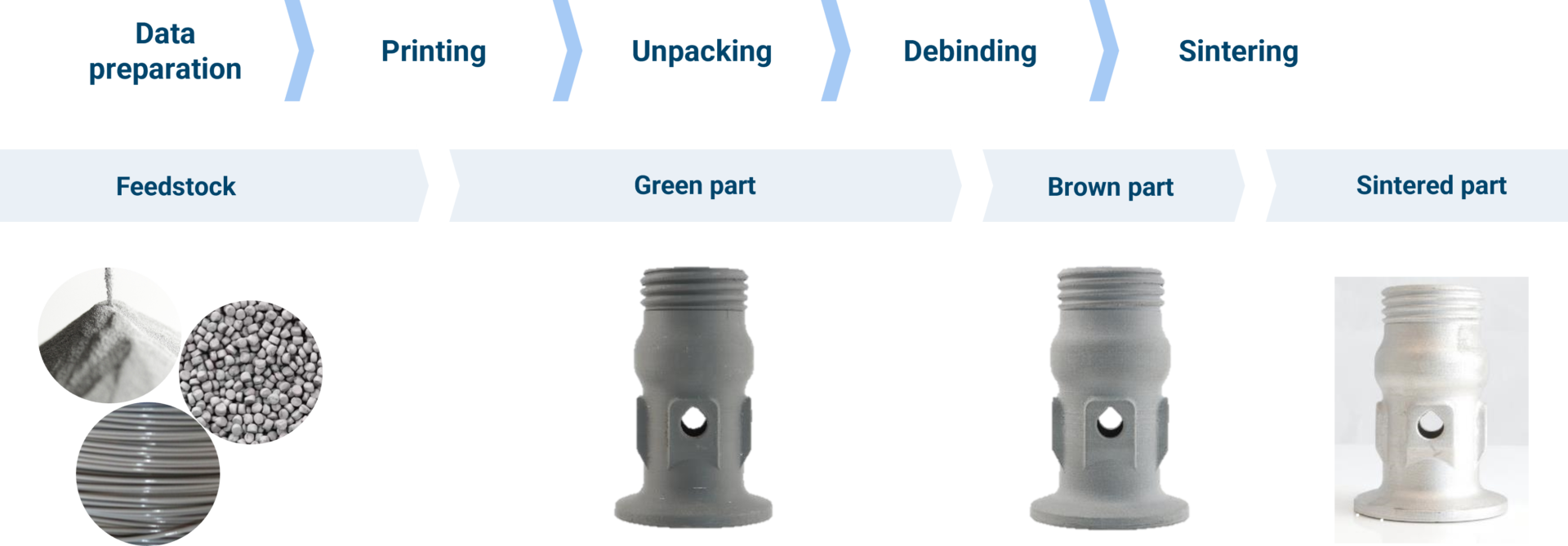

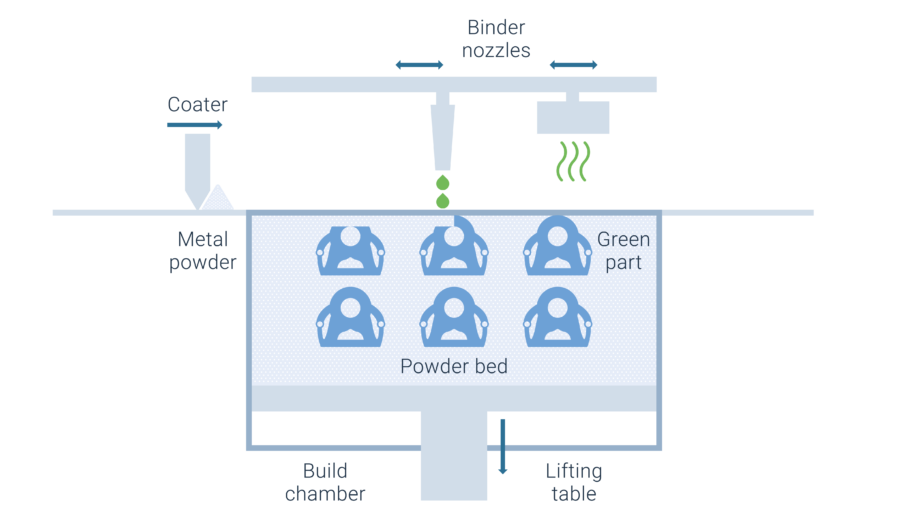

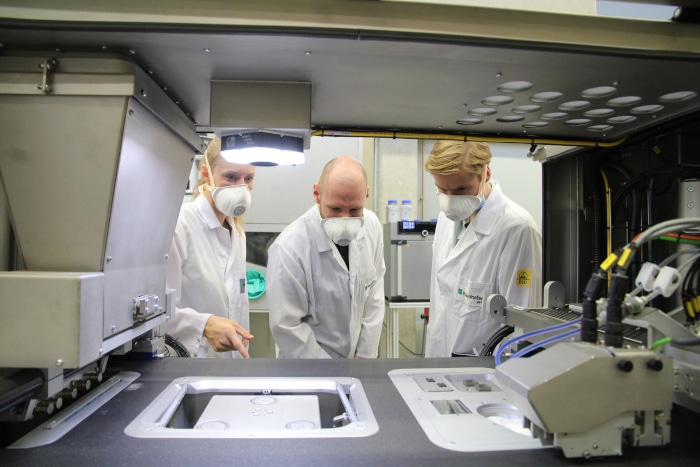

3D Printing training Binder Jetting - Full process chain

Metal Binder Jetting is one of the most promising metal 3D Printing technologies with a high potential for low cost and high-volume digital manufacturing. However, the complete process chain of Binder Jetting is highly complex and the supply chain is still developing. AMPOWER created a unique binder jetting training course in cooperation with the FRAUNHOFER IAPT in Hamburg. Participants will learn the theoretical basics accompanied by a comprehensive hands-on session through the complete process chain.

METAL specialist - Print your own part

Our METAL specialist training is aimed at future machine operators, application engineers and designers in the field of 3D Printing. This 3-day course will give an overview on the various metal 3D Printing technologies, from powder bed fusion and direct energy deposition to sinter-based AM processes. The functional principles, material properties and design guidelines with their advantages and disadvantages of the different metallic processes are highlighted. In addition, the participants will experience the system technology, the set-up and cleaning process as well as the post-processing of metallic 3D printing in a full-day hands-on training session.

Additional topics and trainings

Management, Marketing and Sales

3D Printing enables new business models and can render great benefits. In addition to the fundamentals of Additive Manufacturing, you will learn about key market indicators and their future development in this one-day training course. Using real world examples of applications and new business models, you build a knowledge base to help you make the right decisions in your business.

Quality Management, Documentation

3D Printing poses a great challenge for the quality management of established companies. In this training, benefit from best practices in medical technology and aerospace. Learn how to create the correct specification and documentation for 3D Printing and learn about the key aspects of risk analysis. In addition, the training details quality assurance procedures. Identify the CTQ (Critical to Quality) characteristics of the 3D Printing process.

Process and Manufacturing Optimization

Operational excellence is the foundation of successful 3D Printing. Learn how to identify and measure metrics such as Overall Equipment Effectiveness (OEE) and Key Performance Indicators (KPI) at an Additive Manufacturing facility. Also, find out which process parameters have a significant impact on material quality and how you can optimize your process.

Customized Training

To meet your organization’s specific needs, our experts will design and provide training content and workshops tailored to your requirements. After understanding the goals you want to achieve, a tailored program support your personnel with the right the skill set and motivation.

You are looking for a 3D Printing training with industrial production in mind?

Benjamin Haller

Director Academy

Reach out and send a message to our Director Academy responsible for online and live training.