Materials for metal L-PBF

Materials

L-PBF material variety

For L-PBF a large variety of alloys is commercially available. The most important prerequisite is a good weldability. Furthermore, the material must be available as a powder with a suitable particle size distribution. The powder fraction is system and process specific and differs between about 20 µm to 60 µm. With an adaptation of process parameters larger as well as finer powder fractions are possible, too. Very fine powder fractions tend to agglomerate during handling and coating due to extremely fine dust particles in the distribution and should be avoided.

Typical alloys processed with L-PBF are Ti-6Al-4V, CoCr, stainless and tool steels, nickel-based superalloys, aluminum alloys and also precious metals. High purity copper is difficult in processing with today’s machine systems as the available laser wave lengths is only poorly absorbed.

What you will find in this section

Material overview

Map of LPBF materials

- Stainess Steel

- Maraging Steel

- Nickel Based Alloys

- Titanium Alloys

- Cobalt Alloys

- Copper and Bronze

- Aluminium Alloys

- Precious Metals

Stainless steel is the comprehensive term for a whole group of corrosion resistant steels. All stainless steels are iron-based alloys with a minimum content of 10,5 % chromium. Due to the chromium a self-healing protective oxide layer is formed at the surface, which gives stainless steels their corrosion resistance. Typical representatives commonly used for LPBF are for example steels 1.4404 (316L) and 1.4542 (17-4PH). Research results, process know-how and powder materials are widely available.

Alloy 1.4404 (316L) is the low carbon version of 1.4401 (316) stainless steel. It is commonly used in chemical industry, food processing, medical devices, in marine applications and architectural applications near the seashore.

Alloy 1.4542 (17-4PH) is a martensitic precipitation-hardening stainless steel that provides an outstanding combination of high strength, good corrosion resistance and good mechanical properties at temperatures up to around 300 °C. Specific applications for 1.4542 include the chemical industry as well as use in aircraft parts.

Maraging steel is a low carbon steel with high strength and toughness. The term ‘maraging’ refers to its strengthening mechanisms (martensitic and age hardening). The steel undergoes a martensitic transformation followed by subsequent age hardening. This results in a microstructure with fine precipitates in the martensitic lattice.

For L-PBF, the steel 1.2709 (18-Ni 300) is typically used. It is ideal for many tooling applications such as injection molding, die casting or extrusion as well as for high performance components in demanding industrial applications such as aviation industry.

Nickel-based superalloys are a class of structural materials for high temperature structural applications. They can be operated at temperatures exceeding 1050 °C and occasionally working at temperatures up to the value of 1200 °C. High strength, good fatigue, creep and oxidation resistance when working at elevated temperatures are the main benefits.

The combination of their properties and resistance to surface degradation makes them an attractive material for components used in the hot zones of turbines as combustion chambers or turbine blades.

A widely used representative in L-PBF is the nickel-base alloy 2.4668 (Alloy 718), also known under the brand name Inconel 718. Alloy 718 contains between 50 to 55 % nickel and between 17 to 21 % chromium and small amounts of niobium, titanium and aluminium that enable precipitation hardening.

Other typical alloys include Inconel 625 as well as more specific high-temperature alloys HastelloyX (HX) and Waspalloy.

Titanium alloys are a broad group of lightweight alloys containing titanium and other elements, often aluminum or vanadium. Besides the low density they have excellent corrosion resistance and the ability to withstand extreme temperatures. Furthermore, titanium alloys are commonly used for medical implants owing to their good biocompatibility, high chemical stability in physiological environments and good mechanical properties.

The alloy Ti-6Al-4V (3.7164 / 3.7165), also known as grade 5 titanium, as well as Ti-6Al-4V ELI, grade 23, represents a large amount of total titanium usage. Its usability lies in its many benefits. Ti-6Al-4V can be heat treated to increase its strength and used at service temperatures of up to about 300 °C. Typical applications are in the aerospace, medical, marine and chemical processing industries.

Pure titanium is another material that shows very favorable properties to be used in the medical industry, e.g. for applications such as dental or bone replacement.

Cobalt-base alloys are known as wear-resistant, corrosion-resistant and heat-resistant materials. The most common L-PBF alloy is cobalt-chromium. Cobalt-chromium belongs to the group of bioinert metals, too. In combination with its wear-resistance cobalt-chromium is predestined for use in dental industry as well as for industrial applications such as turbines.

Copper is a soft and ductile metal with very high thermal and electrical conductivity. Bronze is called a copper alloy with at least 60 % copper and different alloying elements, often tin. Copper and bronze are mostly applied in thermal management applications.

Pure copper is difficult to process with L-PBF systems. However advancements in processing strategy, higher available laser power or different laser sources, such as a “green” laser source, enable the production. There are certain copper alloys known that are easier to process by standard powder-bed systems. L-PBF of pure copper can yield electrical conductivity around 100% IACS.

Aluminum alloys contain, besides Aluminum, mostly iron, silicon, copper, magnesium, manganese and zinc. They are characterized by a low density and can, depending on the alloying elements, be hardened and tailored regarding their strength. This permits the design and construction of strong, lightweight structures such as in automotive and aviation industry. Furthermore, aluminum alloys exhibit good thermal conductivity.

Many of the commonly in industry used Al-alloys (5000, 6000, 7000) show poor processability in powder-bed fusion processes and are continuously studied in research.

For L-PBF the alloy AlSi10Mg (3.2381) is commonly used. Heat exchangers are a typical application. Also, in the field of prototyping, Al alloys are used. The high-strength material Scalmalloy was developed specifically for the L-PBF process. It is also applied in heat exchangers and lightweight applications.

At the same time, more specialized alloys e.g. from the 6000 and 7000 series are in development with several companies adding particles to avoid cracking and make them suitable for the L-PBF process.

Alloys of precious metals such as gold and platinum can be processed by LPBF technologies. Precious metals are often used for decorative purposes. For example, jewelry or fountain pens are fabricated additively.

Gold exhibits excellent thermal conductivity and biocompatibility. Thus, it offers high wearing comfort for special medical applications such as dental replacement and restorations in the skull. Due to the excellent electrical properties, high end applications in medical and aerospace industry are a field of application.

Materials for applications

Major AM materials in today's applications

For certain applications some Additive Manufacturing alloys are predominantly used.

The most common materials in medical industry are CoCr and titanium alloys. CoCr exhibits excellent chemical and wear resistance and has therefore been a widely used material in dental industry since decades. In particular, dental copings are made of CoCr. Conventionally the material is centrifugal casted or blanks CNC machined. The copings are cemented into the jawbone and veneered with ceramics.

Endoprostheses for bone replacement, such as hip replacements or knee joint arthroplasty, are made of Ti-6Al-4V, because of its bioinertness and osseoconductivity. The implants are traditionally fabricated by CNC machining.

In both cases, the use of Additive Manufacturing facilitates and enhances the production process. The additively manufactured implants achieve similar mechanical properties to the cast and machined counterparts. At the same time cost-intensive production steps such as additional coatings at the bone-implant interface to facilitate bone ongrowth can be omitted. The AM process enables direct manufacturing of lattice structure that are highly osseoconductive.

In turbine and aviation industry titanium and nickel-based alloys are widely in use. Titanium alloy Ti-6Al-4V is mostly applied in lightweight constructions due to its high specific strength. Alloy 718 is characterized by high thermal stability and utilized as a high-temperature material.

Tool steels are applied for Additive Manufacturing of molds, jigs and manufacturing tools.

Aluminum alloys are used for prototyping and for manufacturing of spare parts of former cast aluminum parts. For automotive industry high-strength alloys (6000, 7000) are of great interest. These are still difficult to process by LB-PBF and thus extensively studied.

Powder production processs

Gas atomization remains the dominant powder production process today

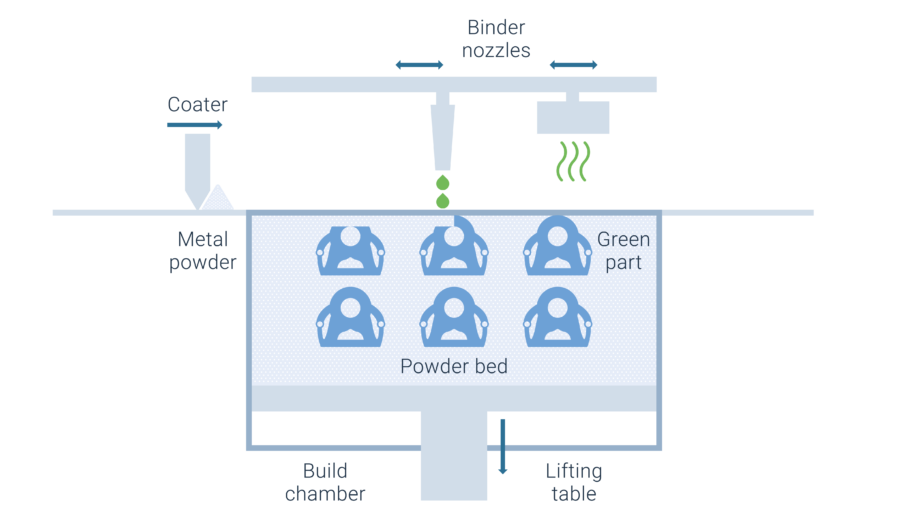

Powder is the most widely used feedstock in the AM industry. Even though the consumption has constantly increased over the years, volumes are still significantly lower when compared to traditional feedstock such as bar materials or wires.

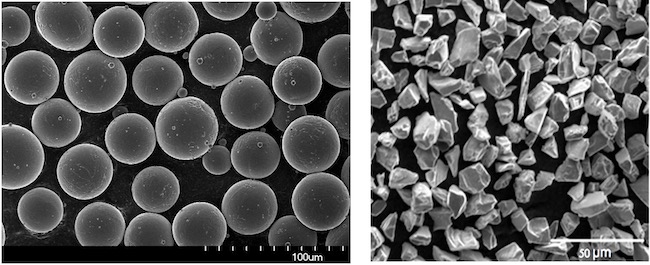

For fabrication of metal powders, the alloy melt is rapidly cooled in an atomization process to form powder particles. Here, two variants can be distinguished, gas atomization and water atomization. The molten metal is poured into an atomization chamber where the melt is fragmented into droplets by high-speed gas or water jets. When the droplets have reached the bottom of the chamber, they have solidified. The main factor which differentiates water atomization from gas atomization is the resulting particle shape. Water atomized powder is highly irregular in comparison to gas atomized powders. Gas atomized powders in contrast have a spherical shape. The heat transfer between the melt and the gas is low and allows the liquid material to form a sphere in flight before solidifying.

So far, mostly gas atomized powders are used for PBF. The spherical structure is believed to have a positive impact on packing density of the powder and the resulting density of the part. Moreover, it allows an even layer application due to its high flowability. Currently, the use of water atomized, irregularly shaped powders is also tested and first acceptable results are achieved.

For L-PBF typically particle sizes around 45 µm are used. Today, the powder is obtained by sieving out the powder fraction between 20 µm to 60 µm from the whole atomized production batch. Due to the additional atomizing and sieving process L-PBF powder is more expensive with prices between 40 EUR/kg to 70 EUR/kg. Current developments to increase the particle fraction will lead to further cost reductions in the future.

Powder quality

Powder characteristics have an important influence on part quality

The characteristics of the powder play an important role in the LPBF process. Some of the most important factors that are typically controlled are the chemical composition, particle shape, particle size distribution, flowability and density.

The particle shape plays an important factor. The L-PBF process works best for spherical particles with a smooth surface and no satellites as can be seen in the left picture. This ensures a good flowability and thus recoating behavior during the process. The particle share is typically inspected directly through a Scanning Electron Microscope, indirect through a hall flow meter or visually.

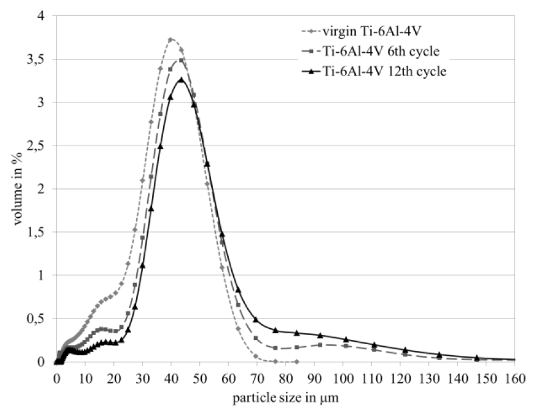

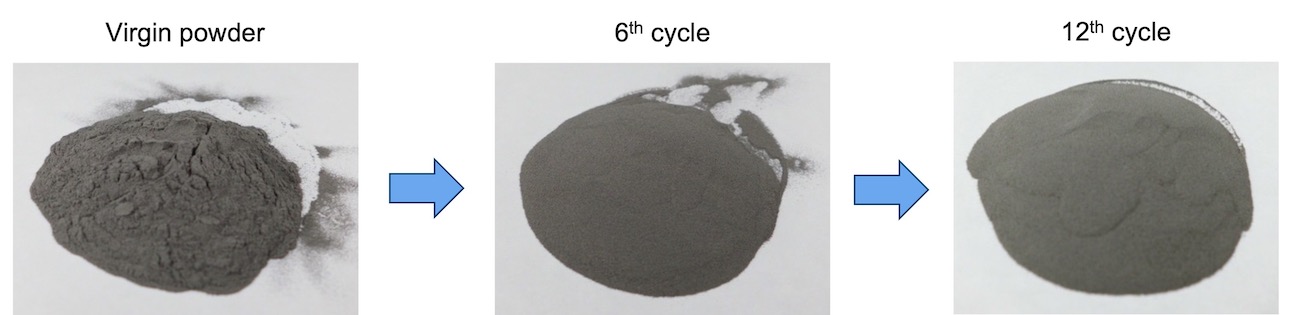

Powder that is used during the L-PBF process but does not end up in the part can be recycled and re-used for subsequent build jobs after a sieving process. The powder quality must be controlled since over time, e.g. through the sieving process or through storage, the powder characteristics will change. The chart on the left compares the particle size distribution (PSD) of Ti-6Al-4V for virgin powder with 6 and 12 times recycled powder. It can be seen that over time, the PSD changes a higher share of larger particles. The reason for this development is that small particles get caught in the filter during the build process and also adhere to bigger particles to form agglomerates. It can be seen in the pictures below the chart how the powder quality changes over time.

In order to avoid changing material characteristics, typically recycled powder is mixed with virgin powder. By regularly refreshing re-used powder, a constant powder quality in terms of particle size distribution, oxygen content and other characteristics can be achieved.

Material outlook

Custom AM materials and future developments

As production processes become established, the development of customized alloys for the respective processes follow. For example in traditional manufacturing, special casting alloys or alloys optimized for cutting and milling processes emerged. For the future of AM alloys, this development is expected, too. The material Scalmalloy provides a first example for an alloy developed and enhanced for Additive Manufacturing. Scalmalloy is an alloy containing aluminum, magnesium and scandium that combines a low density with high ductility and high strength.

The bottleneck in the development of new materials for the L-PBF process is not the powder production itself but rather the development of printing parameters. Developing printing parameters for a new material is still a process consisting of multiple build jobs and Design of Experiments (DOEs) based on employees’ experience. This makes the development of new materials time consuming and costly. Once a printing process resulting in fully dense and crack-free parts has been established, it is generally required to build up a database of material properties over time before it can be used in industrial applications.