Sustainability for Additive Manufacturing

Sustainability for Additive Manufacturing

AM as a tool to reduce the carbon footprint?

Additive Manufacturing is often perceived as a route to improve carbon footprint and is frequently associated with enhanced sustainability. However, the reality is more complex, with the sustainability of AM depending on a wide array of factors. While AM offers unique opportunities to reduce material waste, optimize designs, and enable localized production, it is not inherently more sustainable than traditional manufacturing methods. The ecological impact of AM depends on various factors, including material selection, local energy mix, process efficiency, and the overall life cycle of the product.

To properly evaluate AM’s sustainability, it is necessary to consider both the direct and indirect impacts of the technology. This includes factors such as material extraction, process efficiency, regional energy mix, and end-of-life strategies. Throughout this course, we will provide a comprehensive background on AM sustainability for both metal and polymer-based technologies. By the end of this module, you will be equipped with the knowledge to assess and improve the environmental impact of AM processes.

What you will find in this section

Course Structure & Goals

How the course is structured

This course is structured to guide learners through key aspects of sustainability in Additive Manufacturing:

Metal AM Sustainability Calculation

Metal AM Sustainability Calculation

Polymer AM Sustainability Calculation

Polymer AM Sustainability Calculation

Life Cycle Assessment (LCA)

Life Cycle Assessment (LCA)

Final Assessment

Final Assessment

After taking this course, you will be able to

- Understand the key sustainability factors influencing AM

- Calculate and compare the carbon footprint of AM technologies with conventional manufacturing methods.

- Understand how AM can be used to reduce the carbon footprint along a part's product lifecycle

- Identify best practices for optimizing AM processes to improve sustainability and reduce emissions.

AM Sustainability Calculation

Sustainability during part manufacturing

Understanding the sustainability of Additive Manufacturing (AM) starts with calculating its carbon footprint and comparing it to conventional production. This requires accounting for all emissions, from raw material extraction to the final part.

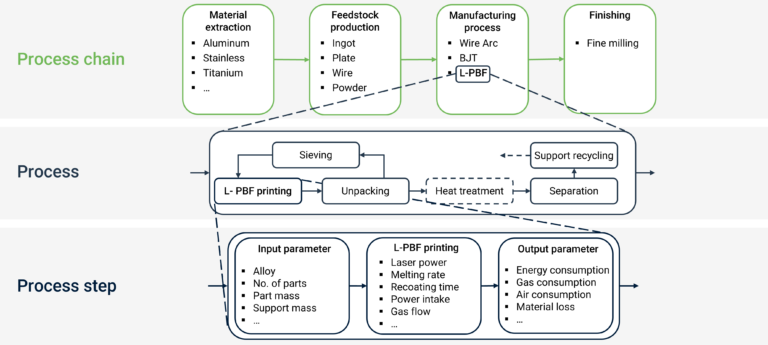

The image above illustrates the CO₂ calculation process. The overall process chain consists of four key steps, applicable to both metal and polymer AM:

- Material Extraction – Sourcing raw materials, including mining metals or producing polymer precursors.

- Feedstock Production – Processing raw materials into printable forms, such as powders, filaments, or resins.

- Manufacturing Process – The AM printing process, where material is selectively deposited, melted, or cured.

- Finishing – Post-processing steps like heat treatment, machining, cleaning, or surface finishing to achieve final part properties.

A deeper analysis is shown using Metal Laser Powder Bed Fusion as an example. Beyond printing itself, related processes such as unpacking, sieving, heat treatment, separation, and recycling must also be considered.

Next, we examine the key variables influencing the carbon footprint, including alloy type, batch size, support volume, and printing parameters like laser power, melting rate, and recoating time.

In the following chapters, we will explore these aspects in detail for both metal and polymer AM, starting with a high-level overview and progressively diving into specific technologies and process steps.

Life Cycle Assessment

The impact of AM along the full lifetime of the part

As mentioned earlier, Additive Manufacturing (AM) may or may not be more sustainable than conventional technologies. The good news is that even if the CO₂ footprint during production is similar or higher, AM can still offer long-term sustainability benefits when used effectively.

To maximize its impact, it is crucial to select the right parts and optimize their design. Simply reproducing a part designed for traditional manufacturing does not unlock AM’s full potential. The true benefits arise when redesigning parts—for example, to reduce weight, enhance durability, or improve efficiency. These optimizations can lead to significant CO₂ savings over the product’s lifetime, often outweighing the footprint of production itself.

We will explore key sustainability drivers and real-world examples in the final section of this course.