Powder DED Applications

Powder DED Applications

Innovative Applications of Powder Laser ED and Cold Spray Technology

Powder Laser Deposition and Cold Spray technology have emerged as versatile solutions in the fields of coating, repair, and blank production. Powder Laser ED excels in enhancing the durability of metallic surfaces, repairing worn components, and creating near net-shaped blanks for cost-efficient machining. Similarly, Cold Spray has proven its value in maintenance and repair, particularly in the aerospace industry, while also finding niche applications in additive manufacturing, especially with high-deposition materials like aluminum and copper. These technologies are reshaping industries by offering innovative and cost-effective alternatives to traditional methods.

What you will learn in this section

Explore Applications

Explore typical application categories for Powder DED technologies

Understand Process Fit

Learn how part geometry, material type, and resolution needs influence which Powder DED technology is most suitable.

Review Real-World Examples

Analyze actual parts made with Powder DED—from turbine blade repairs to gearbox housings and Pelton turbine runners.

Powder Laser ED applications

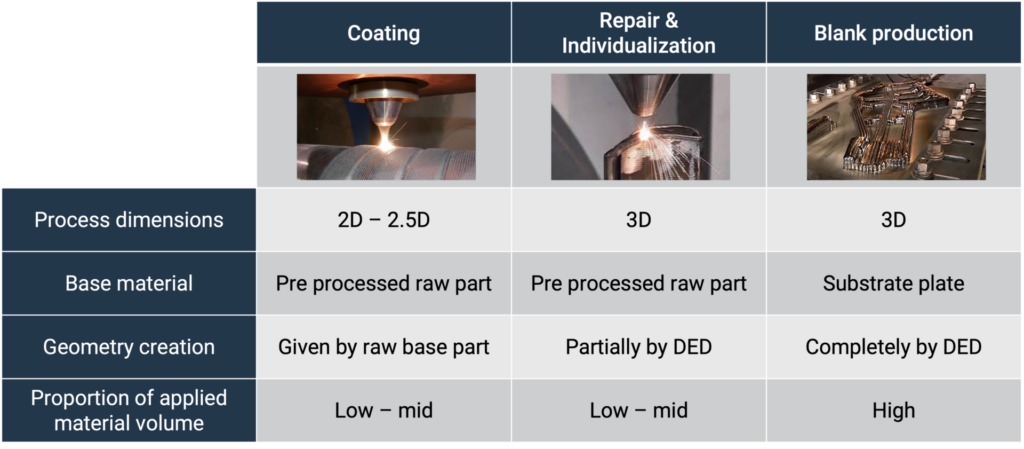

Coating, repair and blank production

Three main fields of applications for Powder Laser Deposition exist. The first application group represents coating of metallic surfaces. Drilling tools for oil and gas industry are examples. These are subjected to large forces and wear and would not reach long lifetimes without protective coating. Such wear protections can be made from different wear resistant alloys and often are a mix of carbides and a nickel-based powder as matrix.

A second typical application group includes the repair of metallic components, such as molds, valves and worn turbine blades. Here, Powder Laser Deposition is replacing many traditional manufacturing processes such as gas metal arc welding and thermal spraying. Besides repair applications, Powder Laser Deposition is also used for local strengthening of structures or for adjustment and individualization of the geometry by locally applying additional material.

The third key application area is the fabrication of near-net-shape blanks for end-part production. These blanks are produced with minimal material offset, enabling efficient and cost-effective subsequent machining. As part size increases, more productive wire-based DED processes are often preferred for producing parts from scratch. This shift is primarily driven by the lower cost of wire feedstock and the higher deposition rates, which together contribute to significantly reduced overall manufacturing costs.

Cold Spray applications

From Repair to Rapid Production of Large-Scale Blanks

Coldspray technology is so far mostly utilized for coating or maintenance and repair. It is a cost-effective process that has shown great potential in the repair of damaged components, due to its capability to avoid any thermal damage to the underlying substrate material. During the past decade, Coldspray has been successfully applied to repair components from aerospace industry. Lately, the technology has been increasingly used to repair critical infrastructure in the defense sector.

Especially the machine technology from SPEE3D, however, is actively targeting dedicated AM applications. Due to the process’s low resolution, the spot size is usually several millimeters in diameter and results in high surface waviness. Overall, it is used to create near net-shape blanks. Especially in aluminum and copper the process yields a very high deposition rate of up to 1,000 cm³ per hour, which results in fast and economic production of low volume blanks. The hybrid system from HERMLE is mostly used to create large hot forming molds with surface conforming cooling channels. For the creation of the channels, HERMLE uses a patented water-soluble material which is subsequently sprayed to the tool steel and dissolved from the mold after the production is finished. This way molds of up to 400 kg of weight can be produced.

Powder vs. wire DED applications

Overlapping Applications, Diverging Strengths

There is significant overlap in applications between wire and powder DED. High-productivity powder DED systems with powerful lasers can rival wire DED. However, for very large or massive parts, wire DED remains the preferred choice.

Today, powder DED is predominantly used for coating, repair, and part individualization. While it can also be applied to produce near-net-shape blanks, this market is currently served almost exclusively by wire DED.

Pipe flange

User

Airbus/PFW

Industry

Aviation

Material

Titanium

Technology

Powder Laser Energy Deposition

Classification

Qualified end part

This aerospace pipe flange of an Airbus 350 is manufactured on a BeAM system in Ti64 in under 2h. Main advantage by material and weight reduction and milling waste reduction. Buy-to-fly ration of 9:1 optimized to 2:1. Courtesy of BeAM.

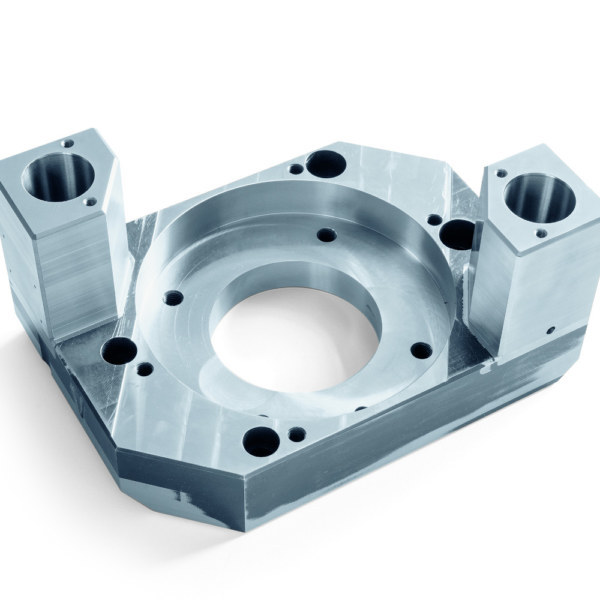

Tooling mount

User

Schaeffler

Industry

Tooling & Molding

Material

Steel

Technology

Powder Laser Energy Deposition

Classification

Tools and fixtures

This tooling mount is usually machined from a complete block. By printing a raw part via powder feed laser energy depositioning, the material amount and cost were reduced. Courtesy of Schaeffler.

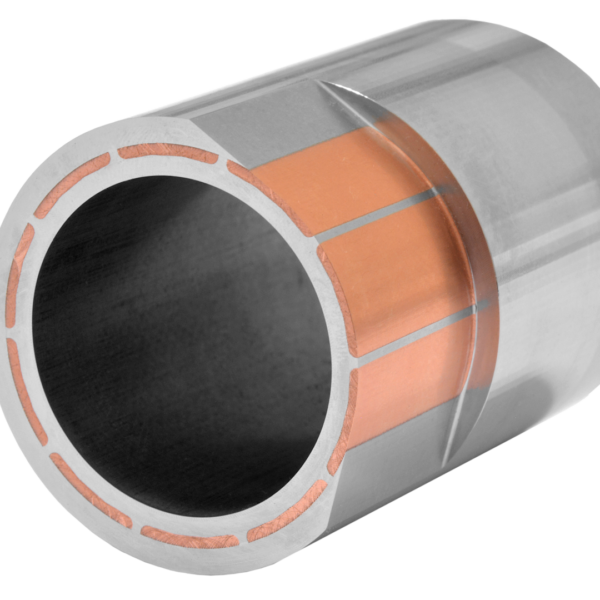

Ring for core mold

User

Hermle Maschinenbau GmbH

Industry

Industrial

Material

Copper

Technology

Cold Spray

Classification

Not qualified end part

This tooling mount is usually machined from a complete block. By printing a raw part via powder feed laser energy depositioning, the material amount and cost were reduced. Courtesy of Schaeffler.

Headlight mold tool

User

Hermle Maschinenbau GmbH

Industry

Automotive

Material

Stainless Steel

Technology

Cold Spray

Classification

Molds

The tool is used to produce head lights for cars. It was produced by Hermle Maschinenbau’s hybrid system of Coldspray and CNC machining. The part includes conformal cooling channels. Due to high surface qualitfy requirements, the tool was highly polished after AM production and CNC machining. No pores were visible. Image courtesy of Hermle Maschinenbau GmbH.