Powder DED Production Cost

Powder DED Production Cost

Understanding Cost Drivers in Powder DED: From Equipment to Deposition Efficiency

Powder DED technologies can offer advantages in production cost compared to other powder-based AM methods such as Powder Bed Fusion —especially for larger parts and high material deposition rates. This lesson breaks down the key cost drivers in Powder DED, including equipment pricing, build rate, material efficiency, and part size impact. Based on real data and process modeling from AMPOWER, you will understand how to evaluate and optimize Powder DED cost per kg.

What you will learn in this section

Understand Cost Drivers in Powder DED

Learn how factors like build rate, machine utilization, and part complexity influence final part cost.

Compare DED with other Technologies

See how DED compares to L-PBF across part sizes and machine configurations.

Discover Strategies to Reduce Cost Per Kilogram

Find out how machine selection, batch size, and build strategy affect unit economics in real-world DED setups.

What you will find in this section

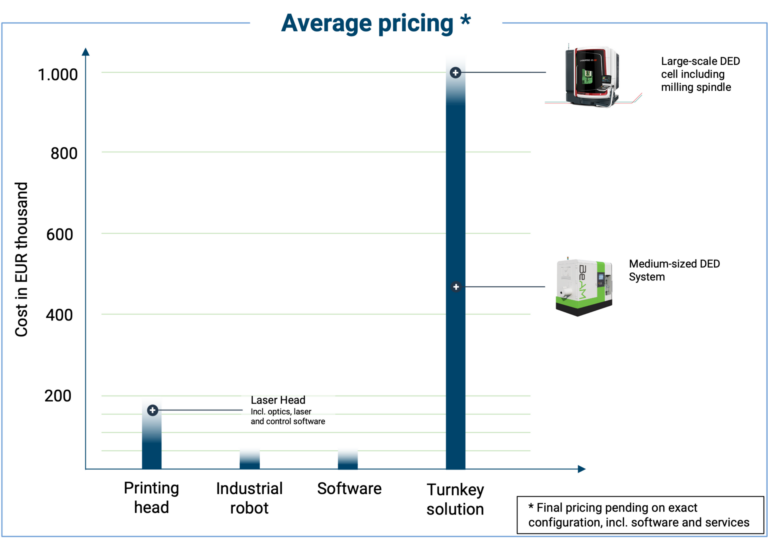

System Pricing

Price Overview on Components for Powder DED Solutions

Powder DED system prices vary significantly depending on a number of factors such as laser power, build volume, and the level of system integration—such as motion control, safety enclosures, and multi-axis capabilities. Entry-level or compact setups can be available for under €500,000, while large-scale, high-power turnkey systems that include additional equipment such as milling spindles or robotic handling can exceed €1 million.

In addition to the core printing system, total system cost is heavily influenced by auxiliary components, such as:

The printing head, which includes optics, laser, and process monitoring tools

An industrial robot or motion platform for toolpath execution

Specialized software for toolpath generation, machine control, and system integration

Finally, turnkey solutions offered by OEMs often include extensive software packages, service contracts, training, and integration support, which add significant value but also raise the investment cost. Choosing the right configuration—tailored to your application type, part size, and automation needs—is essential to achieving cost-effective implementation of Powder DED technologies.

Image sources: DMG Mori, BEAM

Cost Structure Breakdown

Influences on Final Part Cost for Powder DED Technologies

The final part cost in Powder DED is driven by four core areas: data preparation, printing, machining, and quality assurance. Each is heavily influenced by part geometry, batch size, and technology maturity. For small batches, overhead costs (e.g. programming and inspection) are amortized over fewer parts—raising unit costs.

Printing

Printing

- Machine utilization and effective build rate significantly influence production cost

- Nozzle size and resolting resolution with highest impact on printing cost

Quality Assurance

Quality Assurance

- Quality efforts range from basic checks to complete NDT analysis depending on application

- QA costs can reach up to 1/3 of total part cost in AM

- Low batch sizes increase QA cost per part due to limited amortization

Data Preparation

Data Preparation

- High data preparation effort required for complex geometries, especially with 5-axis printing

- Low batch sizes lead to high cost per part, as setup is amortized over fewer builds

Machining

Machining

- Post-processing setup (e.g., for 5-axis machining) requires significant programming effort

- Low volume production leads to higher per-part machining cost

Cost Calculation Assumptions

Assumptions for cost calculation of Wire DED production in 316L

Key Assumptions for DED Cost Calculation

To enable a fair and scalable comparison of production costs across DED and PBF technologies, the following simplifications were made:

Material cost is calculated in €/kg, assuming first-time-right builds.

Build rates are taken as realistic values based on part complexity

Data preparation and post-processing are not included, due to their strong dependence on part design, geometry, and batch size.

Technologies included in the comparison

- Powder Bed Fusion (very large printer)

- Powder Laser Deposition (low resolution nozzle)

- Wire Laser Deposition (single nozzle)

- Wire Laser Deposition (triple nozzle)

- Wire Arc Gantry

- Wire Arc Robot

Provided file /www/htdocs/w01f52a3/wp-content/uploads/2025/05/general-assumptions-cost.xls does not exist!

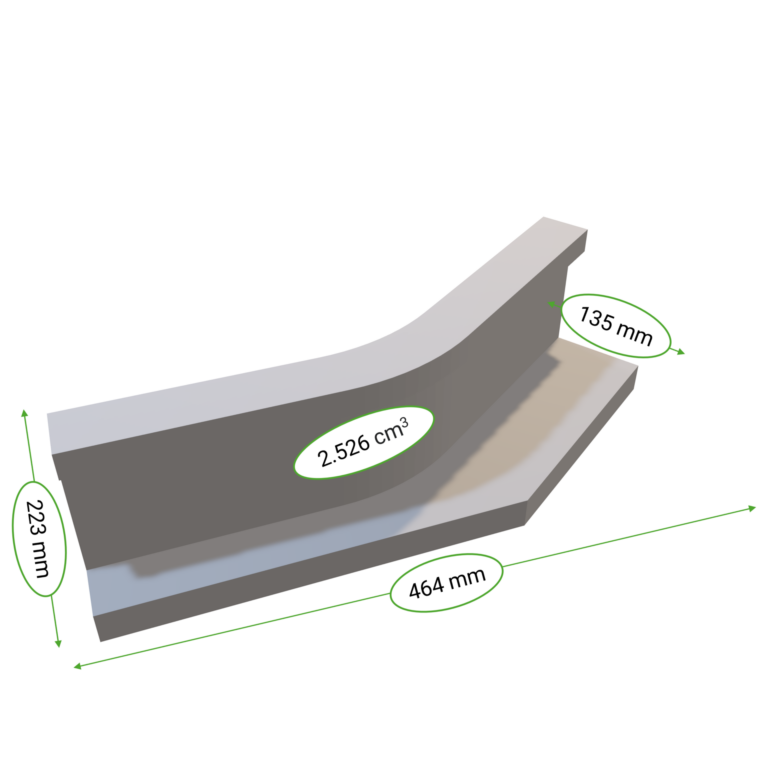

Sample Part used for comparison

The sample part used for the calculation can be seen on the right and is a simple geometry, typical for DED processes. The dimensions are 464 x 223 x 135 mm and a volume of 2.525 cm3. As mentioned above, post processing is not considered in the calculation. However, it needs to be noted that the effort for post processing would vary significantly between the different technologies.

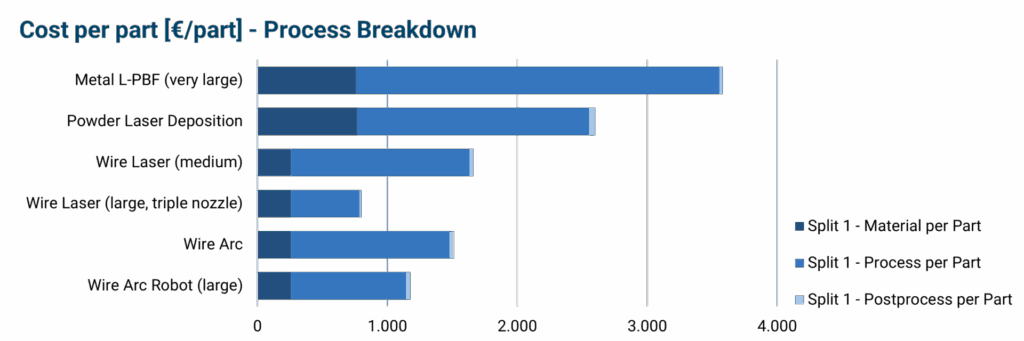

Cost Calculation Example

Influences on Final Part Cost for Powder DED Technologies

The image above compares the cost per part for the previously described sample geometry.

All DED technologies are more cost-effective than Laser Powder Bed Fusion, as the part’s low complexity makes it well-suited for DED. However, it’s important to note that wire-based DED would typically require extensive machining to meet final tolerances. In this analysis, only part separation and heat treatment are included as post-processing steps.

Material costs are slightly higher for powder-based processes than for wire-based ones. The primary cost driver, however, is processing time. Powder Laser Deposition—despite using a low-resolution nozzle—has the longest build time and thus the highest cost per part. In contrast, Wire Laser DED with a triple-nozzle setup achieves the fastest build time and the lowest cost per part.