Powder DED Technology Capabilities

Technology Capabilities

Key Performance Metrics of DED Technologies

This section provides a comparative overview of the most important performance metrics for Directed Energy Deposition (DED) technologies: build rate, cost efficiency, and print resolution. Understanding how these factors vary between processes such as Powder Laser DED, Cold Spray, and Wire DED will help you evaluate the right technology for specific applications and production goals.

What you will learn in this section

Understanding Build Rate

Learn how effective build rate serves as a key productivity metric across different DED technologies—and what drives its variation.

Evaluating Cost Efficiency

Explore how build rate, machine setup, and feedstock type influence the cost per cm³ of DED processes in stainless steel production.

Comparing Print Resolution

Discover the resolution capabilities of each DED technology and how they impact post-processing needs and part complexity.

What you will find in this section

Build Rate

Build Rate as a Key Performance Indicator

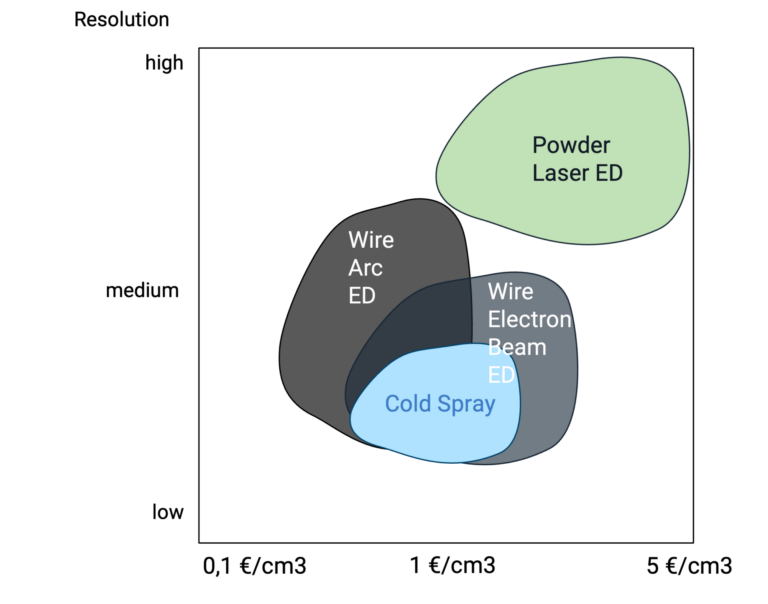

The following chart provides a comparative overview of the effective build rates and typical part sizes for different DED technologies. Please note that the exact positioning of each technology is illustrative only, as it depends on various factors such as machine configuration, nozzle type, and process parameters. The chart is intended to give a relative comparison, not precise performance data.

The effective build rate refers to the ratio of required build volume to actual deposition time, offering a more realistic measure of productivity by accounting for pauses, inter-layer delays, and process interruptions.

For each technology, the chart presents a typical range of build rates along with associated part sizes. The wide variability stems from differences in machine design and nozzle architecture. Depending on the configuration, a system may be optimized for finer features, leading to lower build rates, or for higher deposition speeds, often at the expense of surface quality.

In general, Powder Laser DED tends to achieve lower build rates than Cold Spray or Wire DED, making it well-suited for smaller, detail-focused parts. Cold Spray, on the other hand, supports a wide spectrum of part sizes and delivers the highest productivity among the compared technologies.

Cost

Cost Efficiency of DED Technologies in Stainless Steel 316L

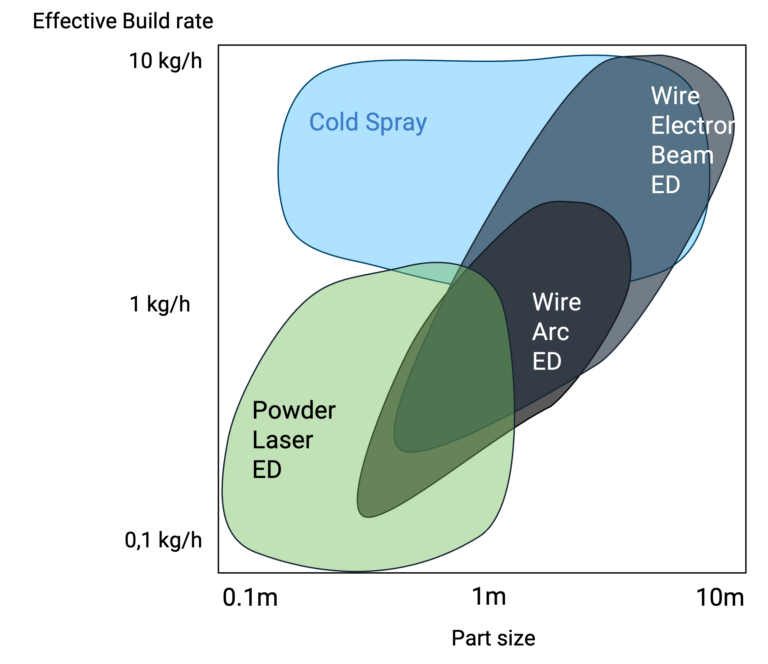

The following chart illustrates the cost per cm³ for different DED technologies, with the effective build rate shown on the vertical axis for reference. The data represents typical internal production costs for Stainless Steel 316L under industrially relevant machine utilization.

The cost ranges reflect differences in machine configurations, nozzle sizes, and process parameters. While the values serve as useful benchmarks, they are indicative only and may vary depending on specific setups.

In general, higher build rates are associated with lower production costs. Powder Laser DED tends to have a higher cost per cm³, mainly due to its lower deposition speeds—especially when fine nozzles are used. Powder feedstock also tends to be more expensive than wire.

By contrast, Cold Spray achieves the highest effective build rates, making it particularly cost-efficient for larger parts. Wire DED also offers favorable cost performance, thanks to its high deposition rates and the use of low-cost wire material.

Resolution

Powder Laser ED with highest resolution of all DED technologies

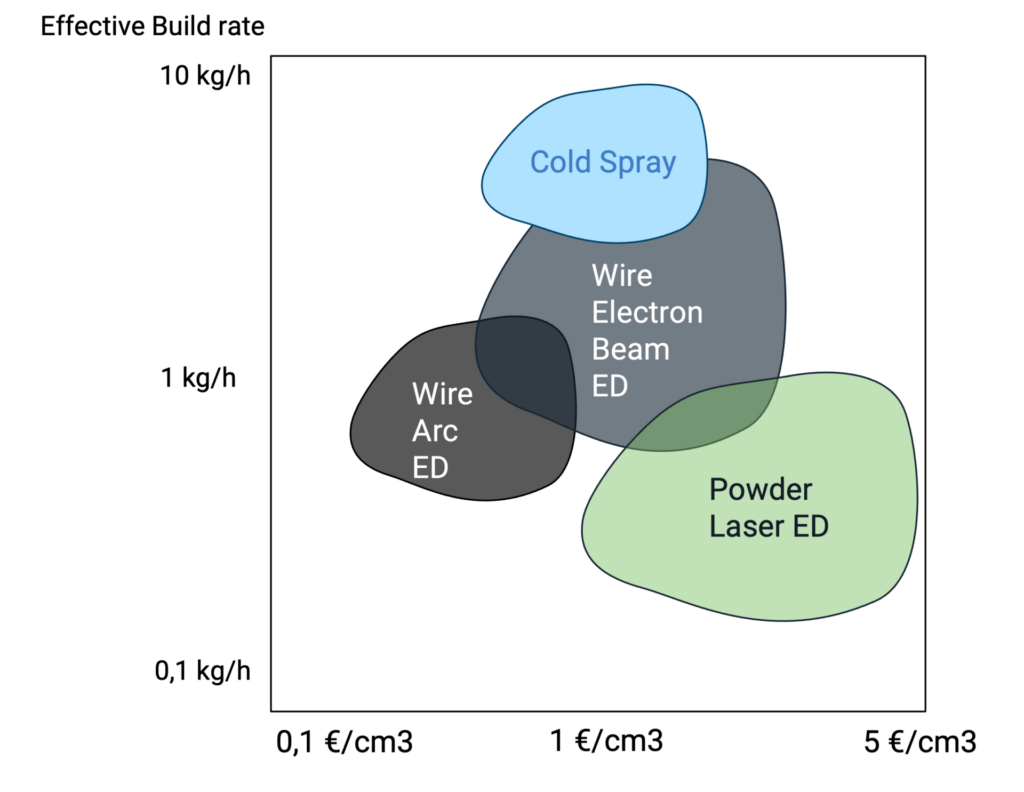

The following chart illustrates the typical as-printed resolution of various DED technologies, plotted against cost per cm³.

Resolution values refer to the surface quality and accuracy in the as-built state, without any post-processing. While most DED parts require machining of functional surfaces, higher as-printed resolution can reduce post-processing time and cost.

Powder Laser DED generally provides higher resolution than Wire DED or Cold Spray, enabling more detailed geometries. However, its resolution is still limited compared to finer AM processes such as Powder Bed Fusion or Binder Jetting, and cannot support features like internal channels or lattice structures.

In contrast, Cold Spray delivers very low resolution and is restricted to simple, bulk geometries, making it unsuitable for applications that require fine detail or precision.