Sinter-based AM process chain

Sinter-based AM - a technology overview

Different printing technologies - one sintering process

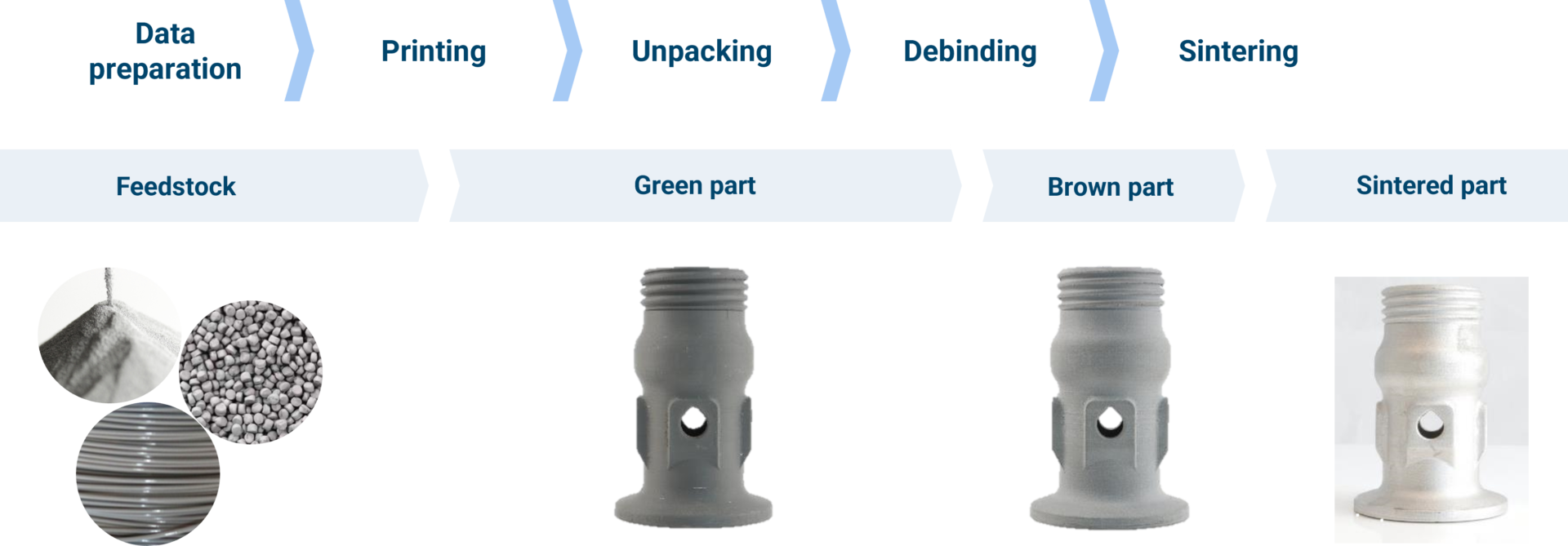

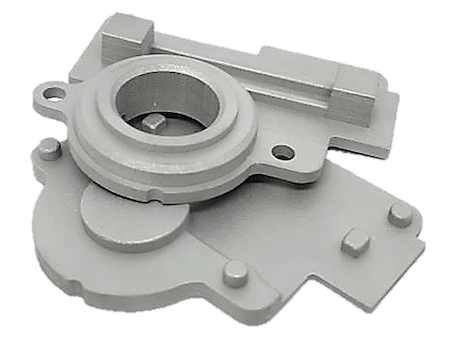

The sinter-based AM (SBAM) technologies have, as the name suggests, the sintering process in common. In this process, the printed green part is consolidated into a dense part and receives its final properties. The green part can be printed in advance using different technologies. They all have in common that metal powder is bound to the desired shape by a binder. The best-known printing technologies are Binder Jetting and Filament Material Extrusion.

In this section, you learn everything about the sinter-based AM process chain and get an overview of the different printing technologies.

Goal and structure of this course

This course is aimed at engineers, designers and other professionals that are working closely with sinter-based AM technologies. The goal is to cover the most important aspects that will enable engineers and designers to fully grasp the capabilities and technical limitations of the printing technologies and the sintering process to succeed in technology selection and part design. Besides going through the course from the beginning until the end, this course can also act as a constant source of knowledge while working on AM projects.

The course is structured into the following sections.

This section will start with an overview of the sinter-based AM process chain and its printing technologies, followed by a technology deep dive into the most important aspects of the BJT technology, followed by a closer look at the debinding and sintering step also including sintering simulation .

The second section will provide an overview of the different materials that are available as well as part characteristics that can be achieved with the BJT process and typical methods for quality assurance. Finally, several common defects in the BJT process are presented.

The last section will act as a guideline for designers. Besides generally describing the process when designing for Additive Manufacturing, actionable restrictions and guidelines for the BJT process are provided. The final section will present several design examples from different industries.

What you will find in this section

Data preparation

From part design to a printing file

The data preparation includes all steps related to the virtual model from initial design to the machine data. This inevitably makes working with the right software the core of this process. Besides the actual 3D modeling software, which in most companies is the CAD-software that is already available, additional software is used for simulation, optimization, slicing, STL file preparation. While most of the steps are similar to the Metal L-PBF process the simulation of the sintering process is unique to the sinter-based AM processes to compensate the shrinkage and potential distortion in the sintering process.

CAD Design

Create the part geometry

Optimization

Improve part performance

STL File Preparation

Convert and clean the mesh

Sintering Simulation

Compensate distortion

Slicing

Generate print layers

Machine Data Export

Prepare final instructions

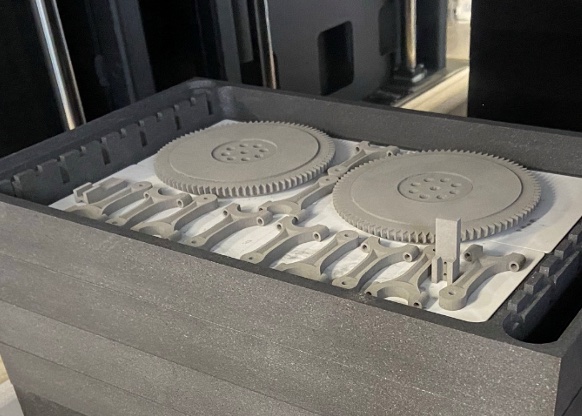

Printing

Variety of sinter-based AM printing processes

The printing process for sinter-based AM technologies varies depending on the process. We will provide an overview of the most common technologies in the following chapter.

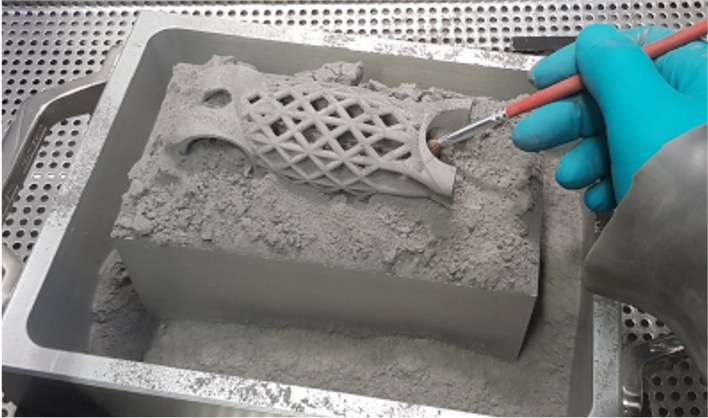

Unpacking

Preparation of the green parts for post processing

After the printing is complete, the green parts are unpacked. This step varies significantly depending on the printing technology. In Material Extrusion, the components simply need to be detached from the building platform. In powder bed based processes like Binder Jetting , the unpacking process is notably more time-consuming.

Parts printed by Binder Jetting are separated from the powder cake and go through a manual depowdering process. Due to the fine powder particle size, the powder cake can be difficult to remove, especially from small cavities. The combination of fragile green parts and a firm powder cake is the reason for a mostly manual process.

After unpacking, the components are placed on trays to be sintered. To control the shrinkage behavior, different support strategies are followed such as life sinter supports made of green parts or ceramic supports that are reusable. Supported surfaces have to be separated by ceramic layers from the actual metal support.

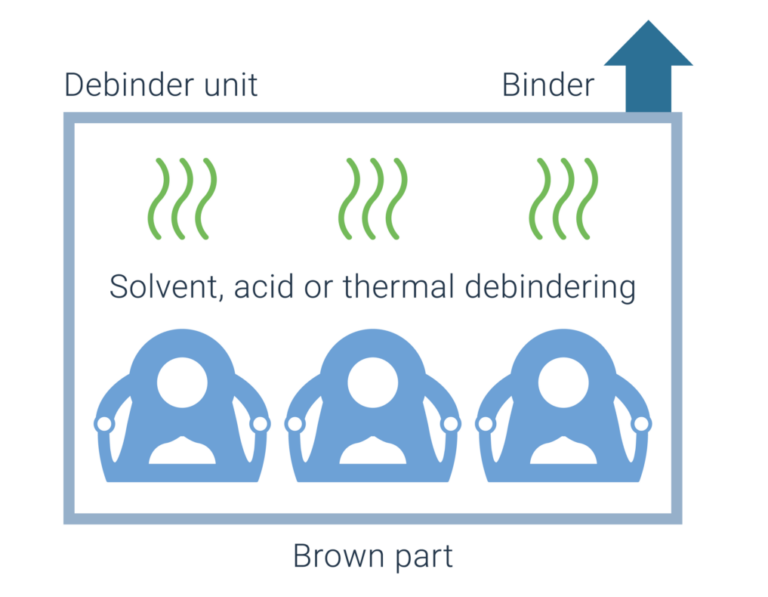

Debinding

Removing the organic binder

The metal powder in the green parts is held in shape by a polymer binder. Prior to the densifying sintering step, it is necessary to remove the binder from the powder body to prevent any chemical contamination.

The debinding process for the green parts depends on the printing technology and the type of feedstock utilized. Certain feedstocks need a solvent or catalytic debinding step, which is followed by thermal debinding. However, thermal debinding is applied across all feedstocks and technologies. In order to streamline the overall process and avoid handling the fragile brown parts, thermal debinding is usually performed in a combined furnace process with subsequent sintering.

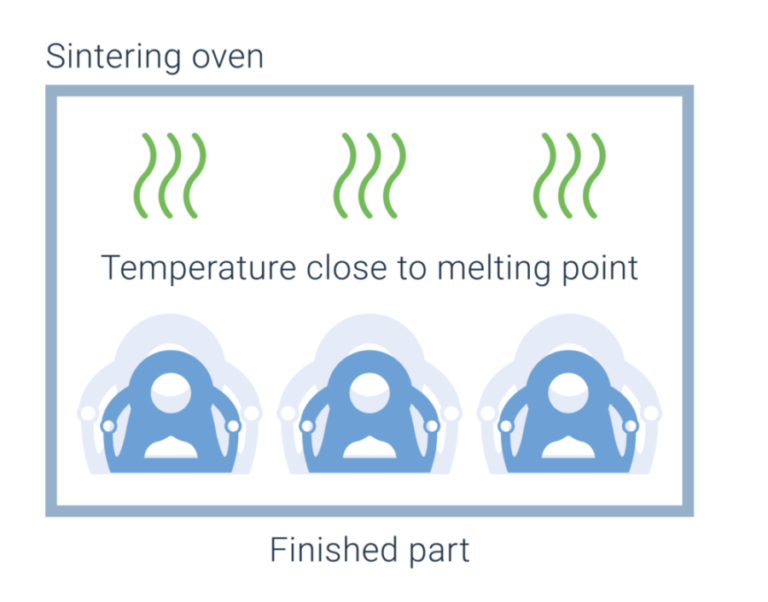

Sintering

Enhancing strength and shrinkage to final dimensions

After the binder is removed, the part is sintered to increase strength and structural integrity. The part is heated close to the melting temperature. The temperature is just high enough to initiate a neck formation at the contact points between the metal particles. In the first sintering stage, channels remain between the necks. In the intermediate stage of sintering, the packing density of the part increases and particles merge. In the final stage, the pore size decreases further.

During the sintering process the part shrinks in all directions of about 16 to 21 %. In z-direction shrinkage is larger than the other two directions due to the influence of gravity. Sinter supports used to prevent undesired deformation have to be removed in a subsequent step.