Introduction to Wire DED

Introduction to Wire DED

From Repair to Production: High Deposition, Industrial Strength

Wire-based Directed Energy Deposition (Wire DED) is a category of metal AM technologies known for their ability to build large parts quickly by melting metal wire with a focused energy source. Whether using electric arc, plasma, laser, or electron beam, Wire DED stands out due to its high deposition rate, material cost-efficiency, and ability to build onto existing components.

This overview introduces the key lessons in the course and summarizes what you’ll learn about Wire DED—from technology fundamentals to process economics and supplier landscapes.

You can then go through the course from start to finish or directly jump to the section you are most interested in.

What you will find in this section

Process Variants & Technology Landscape

Learn how the energy source defines the process—and the supplier ecosystem

Wire DED is not a single technology, but a family of variants distinguished by the energy source:

Wire Arc and Plasma Arc Deposition

Wire Laser Energy Deposition

Wire Electron Beam Energy Deposition

These sub-technologies vary in complexity, precision, and machine availability. Wire Arc is the most widely adopted, but Wire Laser and Electron Beam are rapidly gaining ground due to advances in deposition control and system automation.

You’ll explore how each works, what it’s best used for, and who supplies it.

Applications

See where Wire DED is used—and why it matters

Wire DED is ideal when speed and material volume matter more than ultra-fine detail. Applications include:

Repair & Coating

Repair & Coating

Feature Addition

Feature Addition

Tooling

Tooling

Casting & Forging Replacement

Casting & Forging Replacement

Real examples include titanium brackets for Boeing, turbine runners in hydropower, and gearbox housings in heavy industry.

Digital Process Chain

Understand the digital thread: CAD - CAM - CNC

Wire DED requires a digital toolchain that turns 3D geometry into machine-ready code:

CAD

CAD

CAM

CAM

CNC Control

Tooling

You’ll learn about the challenges of 5-axis programming, geometry simplification, and simulation-based validation—and why toolpath generation still requires expert know-how.

Technology Capabilities

See how each Wire DED system performs in real-world benchmarks

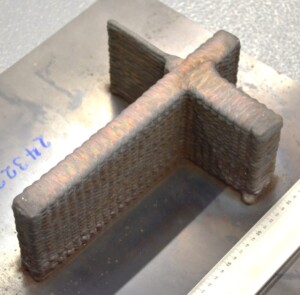

Based on AMPOWER’s benchmark study using 9 real parts, you’ll review:

Build rates

Build rates

Surface waviness

Surface waviness

Minimum wall thickness

Minimum wall thickness

Feature size vs. speed

Feature size vs. speed

You’ll also understand key trade-offs: higher speed often means rougher finish or lower detail resolution.

Production Cost

Understand the cost per kg—and how to reduce it

Wire DED is more cost-efficient than L-PBF for larger parts due to

Cost Structure

Cost Structure

DED vs. L-PBF

DED vs. L-PBF

Cost Reduction

Cost Reduction

You’ll learn about the challenges of 5-axis programming, geometry simplification, and simulation-based validation—and why toolpath generation still requires expert know-how.

Feedstock

Explore wire sourcing, pricing, and quality factors

Wire feedstock is still maturing. This lesson covers:

Sourcing models

Sourcing models

Pricing

Pricing

Delivery formats

Delivery formats

Wire straightness

Wire straightness

You’ll also explore how DIN EN ISO 544 defines wire tolerances, and how container size affects machine uptime.

Standards & Guidelines

Understand how Wire DED is qualified and regulated

Standardization is catching up with industry adoption. You’ll learn: