Powder DED Process Variants and technology suppliers

Process Variants and Technology Suppliers

Introduction to Powder Laser Energy Deposition and Cold Spray

Powder DED Technologies such as Powder Laser Energy Deposition (ED) and Cold Spray are Additive Manufacturing technologies that are used for the production of blanks, but also to repair or coat applications. Powder Laser ED, often referred to as Laser Metal Deposition (LMD), employ a focused laser to melt and fuse metal powders into a dense structure, while Cold Spray uses high-velocity particle deposition at relatively low temperatures, preserving material properties.

This course will provide you with a comprehensive overview of the two technologies.

What you will learn in this section

Understand Powder DED Principles

Learn how Powder Laser ED and Cold Spray work — each with its own working principle and capabilities.

Compare Technologies and Applications

Evaluate the strengths and weaknesses of each Powder DED variant to select the right setup for your use case—whether it’s resolution, material flexibility, or deposition rate.

Navigate the Market and Maturity Landscape

Identify leading OEMs, match machines to application needs, and understand the maturity level of each technology to make informed investment or adoption decisions.

What you will find in this section

Technology Landscape

Navigate the Landscape of Powder DED Variants and Suppliers

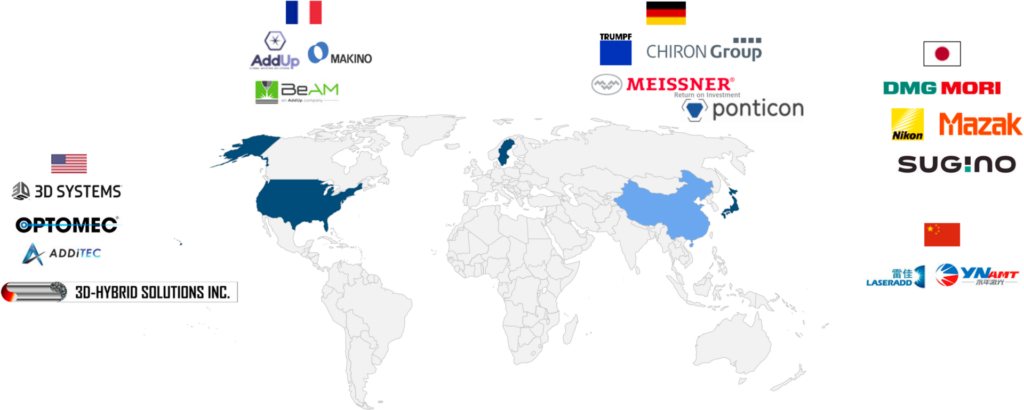

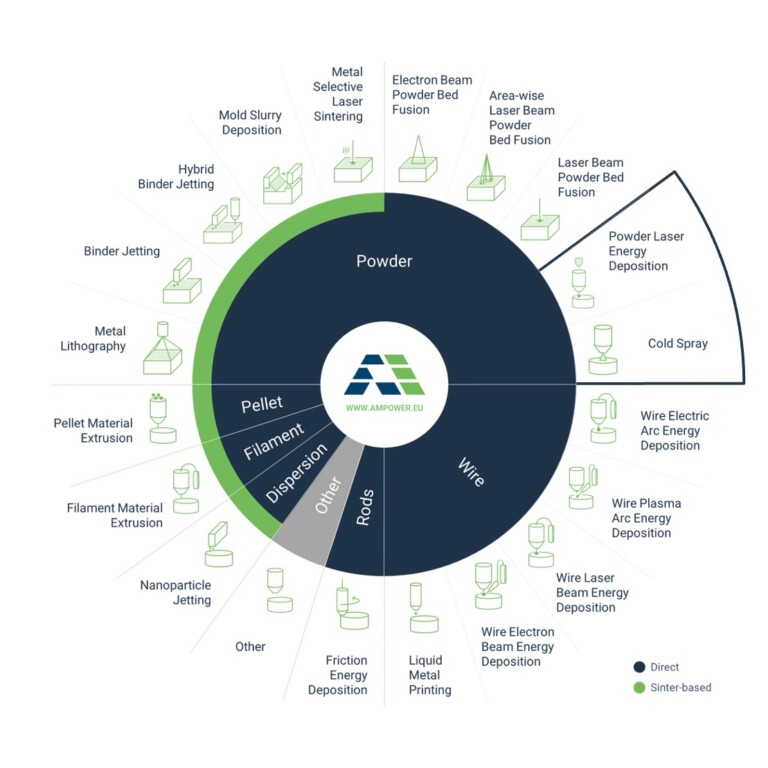

Today, the metal Additive Manufacturing (AM) market includes more than 20 distinct working principles, offered by over 200 OEMs worldwide. These technologies can be broadly categorized into Powder Bed Fusion, Directed Energy Deposition (DED), and Sinter-based AM processes.

Within the DED category, processes can further be classified into powder-based and wire-based systems, which both form a critical and fast-growing segment. The powder DED processes can be split into two sub-technologies, each defined by the energy source used to form the part:

Powder Laser Energy Deposition

- Cold Spray

This course will provide a brief introduction to both Powder Laser Energy Deposition and Cold Spray, highlighting their key principles and typical applications. The main focus, however, will be on Powder Laser Energy Deposition: diving deeper into how it works, what makes it unique, and how it compares to other DED and metal AM technologies in terms of process characteristics, capabilities, and use cases.

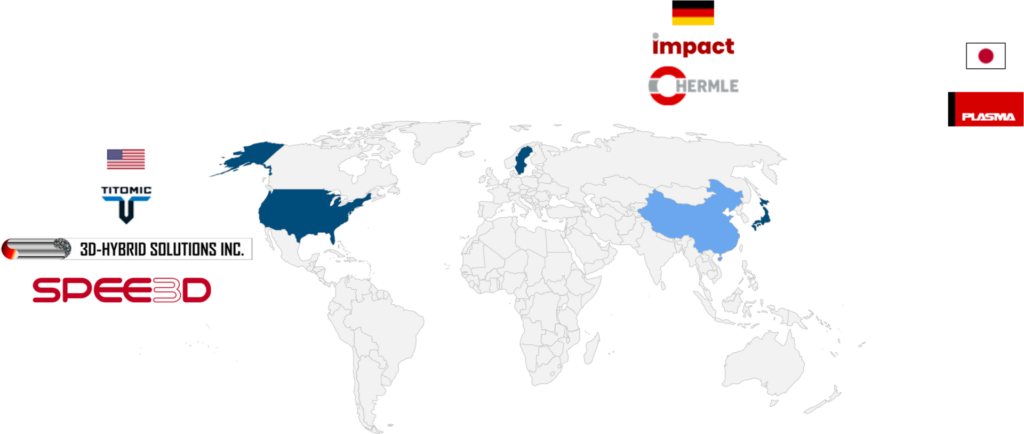

While the number of machine suppliers is still smaller compared to Powder Bed Fusion, the Powder DED ecosystem is expanding continuously. Currently, AMPOWER counts around 40 suppliers of Laser Powder ED systems and only 6 suppliers of Cold Spray technology, reflecting the higher industrial maturity of the former technology.

You can download the latest version of the AMPOWER Technology Map, including a full overview of machine suppliers here.

Powder Laser Energy Deposition

How does Powder Laser Energy Deposition work?

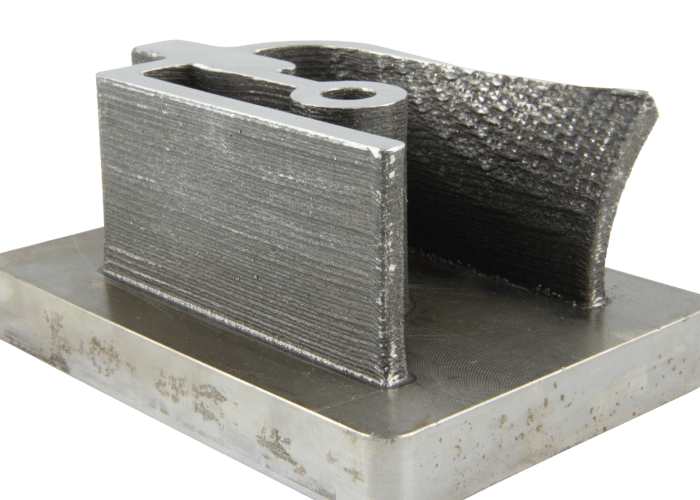

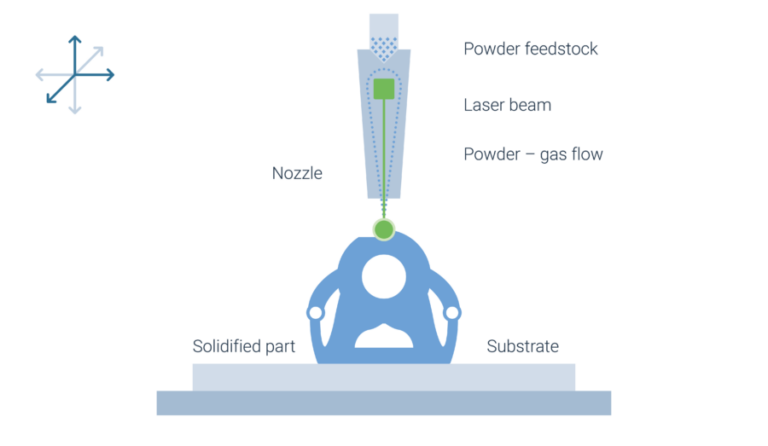

Powder Laser ED, also sometimes referred to as Laser Metal Deposition (LMD), is a welding technology in which a laser forms a melt pool on a metallic parts’ surface. At the same time a powder feedstock is blown through a nozzle into the process zone, where it is preheated by the laser and then absorbed by the melt pool. After solidifying, raised welding beads remain. By repeating the process, the welding beads are built on top of each other and a three-dimensional structure is formed. Powder Laser Energy Deposition is a sub-group of the Direct Energy Deposition technologies. Typical for DED technologies is the high deposition rate of material, which is locally applied to form near net-shape blanks.

Processing unit with multi axis system

The laser beam and the powder supply are combined in a single processing unit, the working head. In a multi axis system typically the working head as well as the substrate plate on which the part is built are fixed to some kind of motion system. The supplier BEAM uses a gantry with five continuous axes for realization of the processing unit’s motion. TRUMPF offers Powder Laser Deposition systems in which the processing unit head is attached to a robot arm. For rotationally symmetric parts, substrate plates can also be fixed to a rotation-tilt table.

Hybrid Powder Laser Deposition technology

In a hybrid system, such as from supplier DMG MORI, the Powder Laser Deposition process is combined with a subsequent CNC machining. The build platform is movable around two axes and the process unit head around three axes. After a section of part or the complete part is built, a milling head is extended and finishes the as-printed parts’ surfaces.

Process video

Below you can see a video of the Powder Laser ED process from Italian machine manufacturer BeAM. They use powder as a feedstock and a laser to melt the powder.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationCold Spray

High-speed impact bonding for AM

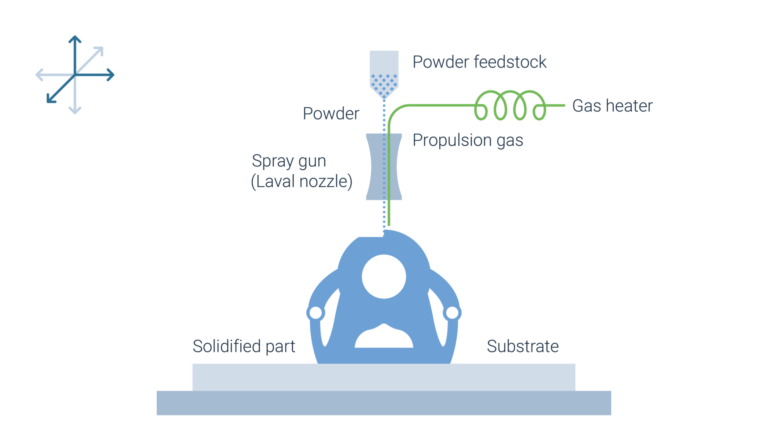

Coldspray is an Additive Manufacturing technology in which powder particles are bonded in solid state only by plastic deformation due to impact. The process uses the energy stored in high pressure compressed gas to accelerate fine powder particles to very high velocities. The kinetic energy of the accelerated powder is transformed to plastic deformation of the particles at impact on the substrate.

Compressed gas is fed via a heating unit to the gun and exits through the nozzle at very high velocity. From a feeder, powder is introduced into the high velocity gas jet. The powder particles are accelerated and directed on a substrate where they deform and bond to form a material layer. By moving the nozzle over the substrate repeatedly, a part can be built up layer by layer. The particles remain in solid state during the whole build job. Thus, the original powder chemistry is retained.

Coldspray machines can be distinguished into high pressure and low pressure spray systems. In high pressure systems, the compressed gas is divided into two streams. One stream passes through a heater and the other stream functions as a carrier gas for the powder particles. The carrier gas passes through the powder feeder, entraining the powder particles. Both gas streams are then mixed before entering a de Laval nozzle. Inside the nozzle the particle loaded gas expands and exits the nozzle with supersonic speed.

In a low pressure system, the powder is directly fed into the gas stream in the divergent section of the de Laval nozzle. Splitting the gas stream is not required. Hence, low pressure Coldspray systems are more flexible and cheaper in equipment and processing costs. Furthermore, the way how the relative motion between the part and the spray gun is realized can differ depending on the machine supplier.

Robot system with moving part

SPEE3D has developed a Coldspray machine in which the substrate is fixed to a robot arm with seven degrees of freedom. The spray gun is stationary while the substrate is moved relatively to it. The substrate can be tilted or moved translationally. By varying the speed with which the substrate passes the powder jet, the thickness of the deposited layer can be adjusted. The system allows high flexibility in part geometry due to the high freedom in motion of the substrate relative to the spray gun. However, part weight and size as well as spraying forces are limited by the strength and stiffness of the robot arm. Mostly very ductile materials such as aluminum and copper are processed with this set-up.

Gantry system with fixed part

A different approach in machine design has been created by the supplier TITOMIC. The substrate is fixed to a work table that can fulfill a translational movement. The spray gun is attached to a gantry via a robot arm. The stiffer set-up allows the use of larger more powerful spray guns and therefore the processability of less ductile materials.

Hybrid CNC machine-based system

HERMLE uses a similar approach for their Coldspray production service, integrating the spray gun into a multi-axis CNC system. The substrate is fixed to a rotation-tilt table while the spray gun has additional three degrees of freedom allowing for multi-dimensional relative movement. The set-up allows large and heavy parts of up to 400 kg to be build. The utilization of a high-power spray gun enables the processability of less ductile materials. Additionally, the system can utilize a milling spindle to machine the sprayed part in between single layers or after finishing the part. This enables high accuracies and a defined combination of multi-material. HERMLE uses this approach to build cooling channels, that are filled with a water-soluble material during spraying and cleared by a saline solution when the part is finished.

Process video

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationTechnology Maturity

Additive Manufacturing Maturity in Industrial Use

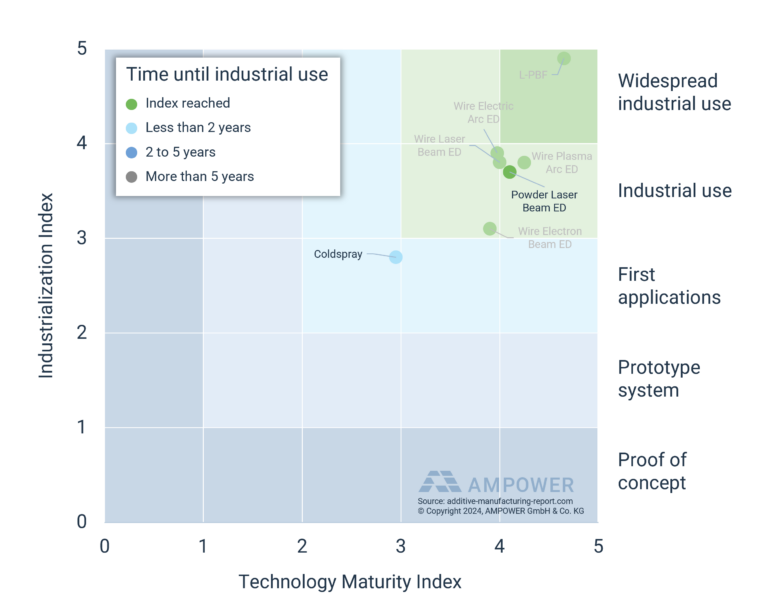

To evaluate the different AM technologies AMPOWER has developed a model to characterize the maturity of an Additive Manufacturing technology based on two indices. The Industrialization Maturity Index and the Technology Maturity Index describe and compare the capabilities and adoption rate of each AM technology in the industrial environment. Both indices are crucial factors for evaluating the current status of any AM technology. Each category is weighted according to its specific importance. Typically, the technological maturity increases first, and the industrialization follows.

Technology Maturity Index

Technology Maturity Index

Industrialization Index

Industrialization Index

As of 2025, Powder Laser ED has a relatively high maturity , positioned similarly to wire-based DED systems in terms of industrial readiness. It has firmly established itself in repair and coating applications, where its precision and material flexibility offer significant advantages. While there is ongoing debate about whether such applications truly fall under the definition of Additive Manufacturing, the addition of small features, material build-ups, or complex geometries during repair is commonly marketed as AM, particularly when it enables cost savings or performance improvements.

The technology has proven its value in restoring worn high-value components, such as turbine blade tips, injection molds, or tooling surfaces. However, beyond these use cases, it continues to face challenges in expanding into broader, non-coating business applications across multiple industries. Despite its technical capabilities, the adoption of Powder Laser DED for full-part production remains limited.

The supplier landscape is relatively stable, with a few well-established players focusing on niche industrial segments. This specialization, combined with consistent process performance, contributes to its high maturity index. Yet, there has been little innovation or diversification in recent years, suggesting a plateau in its evolution within the broader AM ecosystem.

Cold Spray Additive Manufacturing did not advance in the Maturity Index in 2024. With predominantly two major players in this technology field (SPEE3D and TITOMIC) the current focus remains primarily on Defense and Space applications. Backed by current geopolitical developments, SPEE3D is promoting a compact, container-based solution for deployment in combat zones, enabling fast and easy repair and spare part production. TITOMIC targets applications involving titanium and steel, which they can process using their high-power gun and large stationary systems. With the current rise of Wire ED technologies, Cold Spray will need to prove its place in the AM landscape in the coming years to successfully reach “Industrial Use.”