A Brief history of Additive Manufacturing

History

Industrial Additive Manufacturing overcoming the hype

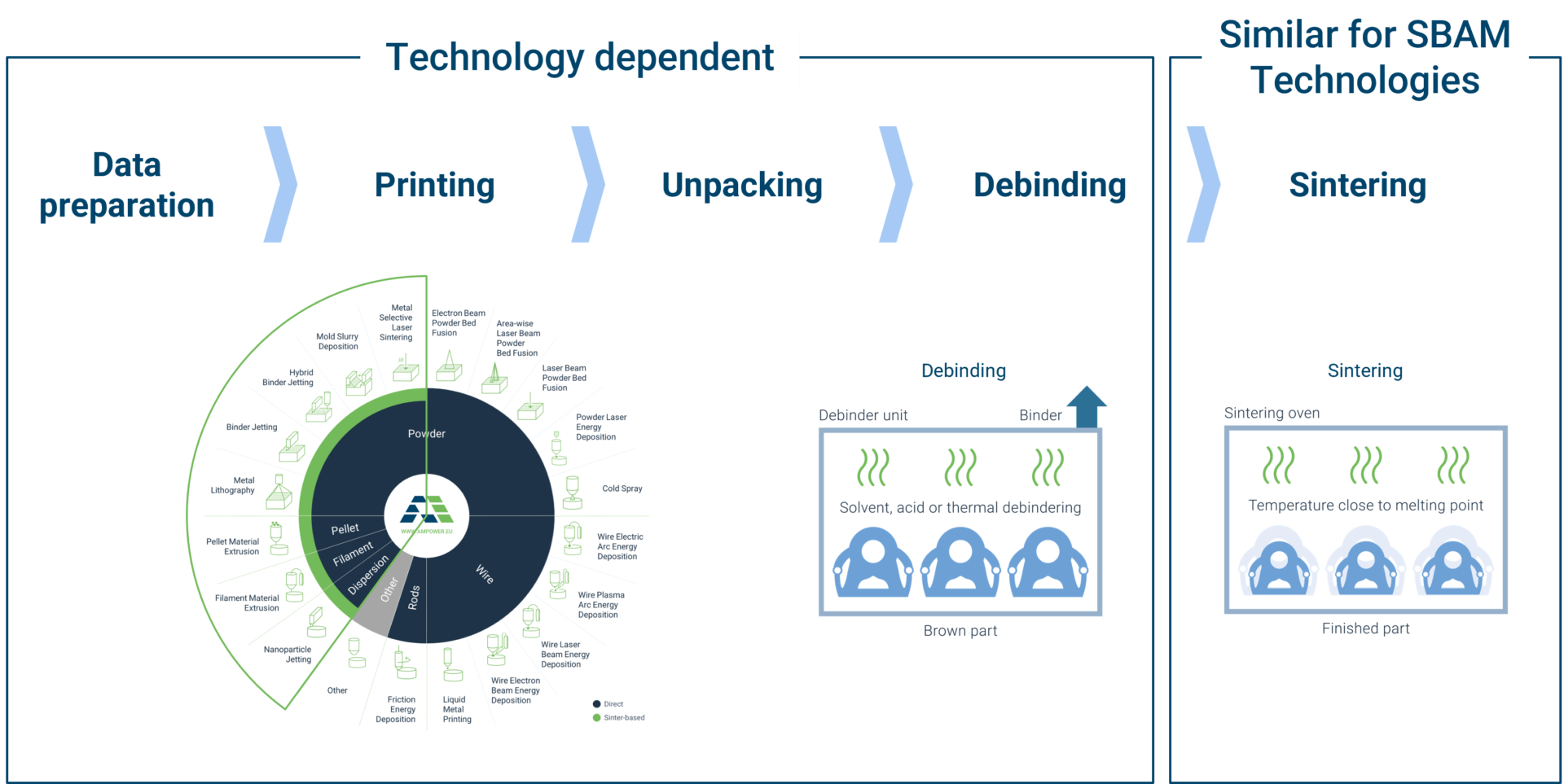

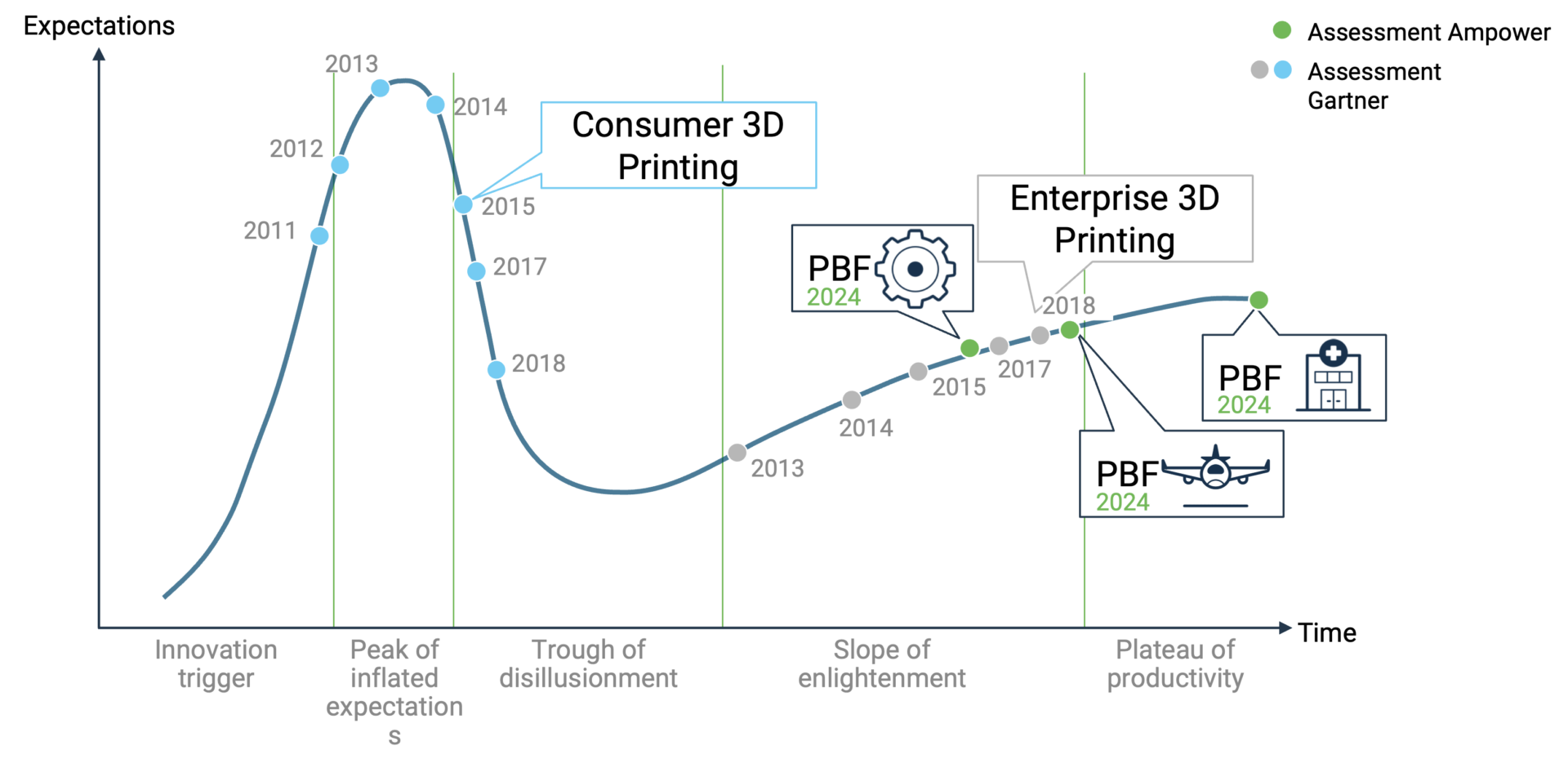

Over the past years, Additive Manufacturing has seen a rapid development. Starting from a technology that was mainly used for prototyping in the 90s, Additive Manufacturing has come a long way. We will use the Gartner Hypecycle to display the different cycles the technology has gone through over the last 10 years.

It needs to be noted that it is hard to pinpoint the exact location of a certain technology or industry on the hypecycle. To make a more accurate statement, each application should be placed individually on the hypecycle. The technologies and industries that are described in the following thus need to be seen as aggregation of the respective applications.

Consumer 3D printing, which has seen a massive hype in the early 2010s, is currently stuck in the “trough of disillusionment“. While in the past people thought in the future every private person might have a 3D printer at home, this is today only true for a small niche.

Enterprise 3D printing, on the other hand, has already passed the trough and has according to Gartner continued to go through the “slope of enlightenment” between 2013 and 2018.

Looking at Additive Manufacturing across different industries and technologies, we consider that mature technologies such as Powder Bed Fusion (PBF) are generally still somewhere in the slope of enlightenment. The medical industry can be seen as an exception that has already reached the “plateau of productivity“. We expect further industries, such as the space sector, follow in the years to come.

A more detailed discussion of the maturity of different AM technologies can be found in the courses on Metal and Polymer technologies.

The early days

Science fiction and enabling technologies

Reading up on the historical developments on the AM market helps to understand how the market has evolved into what it is today. We will give an overview of what we consider the most important developments since the 1980s. Before that we would like to take a brief look back at the time before that.

One of the first persons to describe what we call 3D-printing today was American science fiction author Raymond Fisher Jones. Jones published the short story “Tools of the Trade” that appeared in the November 1950 issue of Astounding Stories. Even though he referred to it as “Molecular Spray”, this is often considered to be the first story dealing with 3D printing.

In the following, years underlying technologies that would later enable the emergence of 3D-printers, have developed. Most notably these technologies include computer aided design (CAD), advancements in computers and the possibility to process large amounts of data, as well as rapid developments in laser-technologies.

1980s

The first patents around 3D-Printing

The early developments of 3D printing started with a range of patents around building up parts layer-by-layer across Japan, France and the USA in 1984. These patents emerged into the first companies commercializing Additive Manufacturing in the subsequent years. During that time technologies such as Stereolithography, Selective Laser Sintering (SLS) and and Fused Deposition Modeling (FDM) emerged.

Application of Stereolithography patent by Charles Hull

In 1984, Chuck Hull applies for the Stereolithography patent. The technology develops into one of the most widely used technology for rapid prototying in the years to come.

Read More19843D SYSTEMS market entry

Chuck Hull co-founded 3D SYSTEMS in the same year that his patent is granted in the USA. In 1987, 3D SYSTEMS launched the first 3D printer, the SLA-1.

Read More1986Application of the SLS patent by Carl Deckard

Carl Deckard files the patent for the Selective Laser Sintering (SLS) process. Shortly after Deckard founded the company DTM, that was acquired by 3D SYSTEMS.

Read More1989Application of the FDM patent by Scott Crump

In 1989, Scott Crump applies for the Fused Deposition Modeling (FDM) patent. In the same year he founds STRATASYS, which remains one of the leading companies in the market until today.

Read More1989Machine Supplier EOS is founded

In 1989, machine supplier EOS is founded by Dr. Hans Langer. The company later evolves into one of the leaders of industrial Additive Manufacturing.

Read More19891990s

The commercialization begins

During the 1990s, more and more companies started commercializing various 3D printing technologies. At the same time, the first metal processes were patented and started to be commercialized.

Service bureau and software supplier MATERIALISE is founded

In 1990, the company MATERIALISE is founded in Belgium with one Stereolithography machine. The company later developed into one of the leading service bureau and software supplier in the AM market.

Read More1990Direct Metal Laser Sintering (DMLS) introduced by EOS

The German machine OEM EOS introduces the EOS M160, their first metal printer. As the name suggests, the laser was not actually melting the metal but it was rather a sintering process.

Read More1994Metallic laser 3D printing patent filed by FRAUNHOFER

Wilhelm Meiners, Konrad Wissenbach and Andreas Gasser file the patent for metal laser 3D printing. The technology has since then evolved into the most widely used process for metal Additive Manufacturing.

Read More1996EBM machine supplier ARCAM is founded

In 1997, the Swedish company ARCAM producing Electron Powder Bed Fusion (E-PBF) machines is founded. The company then became a leader in E-PBF technology before being acquired by GENERAL ELECTRIC in 2016.

Read More19972000s

Growing popularity of 3D printing

Metal 3D printing saw a strong rise, especially among german companies. At the same time, 3D printing gains more popularity in the consumer world.

Laser Cusing machine launched by CONCEPT LASER

In 2001, the German manufacturer of Powder Bed Fusion machines CONCEPT LASER introduces its first metal machine with the Laser Cusing process.

Read More2003TRUMPF discontinues AM activities

In 2006, only 3 years after entering the metal AM market, TRUMPF discontinues their AM activities.

In 2014, TRUMPF reenters the AM market.

Read More2006Service bureau SHAPEWAYS is founded

In 2007, the Dutch service bureau SHAPEWAYS is founded.

Read More20072010s

Widespread Adoption of Additive Manufacturing

During the 2010s, AM has started to become a main production technology in several industries. Led by the medical and aerospace industry, both OEMs and AM users have made significant investments into technologies and production facilities.

GE AVIATION acquires MORRIS TECHNOLOGIES

In 2012, GE AVIATION acquires the metal AM service bureau MORRIS TECHNOLOGIES. This cements their position as one of the leading AM users in the aerospace industry.

Read More2012First Material Extrusion patents expire

In 2013 patents from polymer Material Extrusion (ME), a polymer-based AM technology, expired and low cost ME printers were pushing into the consumer market.

2013DESKTOP METAL is founded

In 2016, DESKTOP METAL is founded to introduce their Metal Binder Jetting Technology. The company has since then acquired several companies, such as EXONE, and grown to over 1000 employees.

Read More2016GE buys CONCEPT LASER and ARCAM

In 2016, GENERAL ELECTRIC acquires the two machine manufacturers CONCEPT LASER and ARCAM.

Read More2016HP MJF Technology Launch

Introduction of HP’s Multi Jet Fusion (MJF) technology, revolutionizing 3D printing speed and precision.

Read More2017Relativity Space’s AM Milestone

Relativity Space announces Terran 1 Rocket with 90% of its components additively manufactured.

20182020s

AM Industry Faces Post-Hype Challenges

The early 2020s brought a turbulent business climate, marked by the COVID-19 pandemic, geopolitical tensions, and economic instability. Following initial excitement, the AM sector faced slowed growth and consolidation, as companies grappled with supply chain disruptions and recalibrated expectations. However, success stories continue to emerge, and the technology matures with industrialized applications showcasing its transformative potential.

Desktop Metal Goes Public

Desktop Metal goes public with a valuation of $2.5 billion, fueling growth in the AM industry.

Read More2020SLM Solutions launches NXG XII-600

SLM Solutions launches the NXG XII 600, a breakthrough in high-speed laser powder bed fusion technology.

Read More2021GE Introduces Metal Binder Jetting

GE Additive introduces Binder Jet Technology, advancing industrial-scale metal printing.

2022EPlus-3D’s Large-Scale Machine

Chinese supplier EPlus-3D unveils a 64-laser machine, increasing scalability for AM. Other Chinese suppliers such as BLT and Farsoon are also entering the European market with large-scale printers.

Read More2023Nano Dimension Acquires Desktop Metal

Nano Dimension acquires Desktop Metal and Markforged, consolidating AM capabilities in a $295M deal. This marks a significant devaluation of the 2 acquired companies, previously valuing several billion USD.

Read More2024