AM process overview

Which Additive Manufacturing processes exist?

Understanding the different technologies is arguably one of the most important skills to master when starting to work with Additive Manufacturing. However, this has become increasingly difficult in the past few years: Almost every week, a new industrial AM machine OEM is emerging on the market. This section will provide an overview of different technologies as well as the overall AM workflow.

What you will learn in this section

Classifying AM Technologies

Understand how AM processes are categorized by feedstock and standardized into 7 official process types (ASTM/ISO 52900).

The Additive Workflow

Learn the full AM process chain—from CAD file to finished part—and how it differs depending on the technology used.

Processes in Action

Watch key AM processes in motion and connect theory with real-world applications across metal and polymer technologies.

What you will find in this section

Technologies by feedstock type

Metal and Polymer AM landscape

Over the last three decades, more and more Additive Manufacturing processes have emerged and there are numerous ways to classify them. One common way is to classify processes by baseline technology, e.g. laser-based processes or extrusion processes etc.

Another common classification is by feedstock type, i.e. powder, filament or wire. The following maps provides a good overview of the different polymer and metal processes divided by feedstock type. These maps will be further discussed in the online learning courses on metal and polymer technologies. We highlighted some of the most common processes in the circles.

Metal Additive Manufacturing Process Landscape

Electron Powder Bed Fusion

Laser Powder Bed Fusion

Powder Laser Deposition

Coldspray

Wire Arc Deposition

Metal Material Extrusion

Binder Jetting

Polymer Additive Manufacturing Process Landscape

Vat Polymerization

Powder Bed Fusion

Material Extrusion

Process categories

The 7 official process categories

A further way to classify technologies today is by 7 main categories defined by ISO and ASTM in the standard 52900-15. We will briefly give an overview of the 7 categories including process description, material categories, typical applications and AM process variants, followed by videos of some of the most common AM processes below.

Process description:

A liquid bonding agent is selectively deposited to join powder materials.

Materials:

Metal and sand

Typical applications:

- Serial metal parts ≈500-20.000

- Printing of sand molds

AM process variants – a selected overview

- Binder Jetting (BJT)

- Multi Jet Fusion© (MJF)

Process description:

A focused energy source used to fuse materials as they are being deposited.

Materials:

Metal

Typical applications:

- Repair/coating of shafts for oil & gas/heavy duty machinery

- Aviation Ti parts

AM process variants – a selected overview

- Laser Engineering Net Shape (LENS)

- Electron Beam Additive Manufacturing (EBAM)

- Rapid Plasma Deposition

Process description:

Material is selectively dispensed through a nozzle or orifice.

Materials:

Metal, polymer and composite

Typical applications:

- 3D printing @ home

- High performance polymers (e.g. PEEK)

AM process variants – a selected overview

- Fused Deposition Modeling (FDM) – Polymer

- Arburg Plastic Freeforming (APF) – Polymer

Process description:

Droplets of build material are selectively deposited.

Materials:

Metal, polymer and wax

Typical applications:

- Multicolor/-mate-rial prototypes

- Wax patterns for jewelry

- Molds for investmment casting

AM process variants – a selected overview

- Material Jetting (MJ) – Polymer

- Multi-Jet Modeling (MJM) (also: MultiJet Printing (MJP), PolyJet) – Polymer

- NanoParticle Jetting (NPJ) – Polymer

Process description:

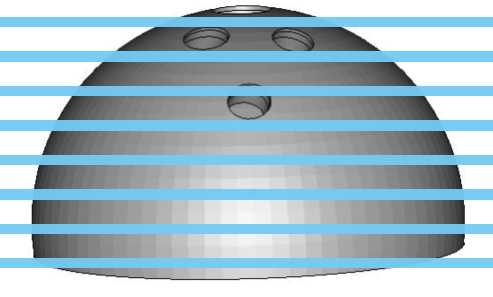

Energy source selectively fuses regions of a powder bed.

Materials:

Metal and polymer

Typical applications:

- Polyamer prototypes

- Complex metal parts: Implants, fuel nozzle, turbine blades

AM process variants – a selected overview

- Laser-beam PBF of polymers (L-PBF) (also: Selective Laser Sintering (SLS)) – Polymer

- LB-PBF of metals (L-PBF) (also: Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), Laser Metal Fusion (LMF)) – Metal

- Electron beam PBF of metals (E-PBF) (also: Electron Beam Melting (EBM)) – Metal

Process description:

Sheets of material are bonded to form a part.

Materials:

Composite, paper

Typical applications:

Full color paper prototypes

AM process variants – a selected overview

- Laminated Object Manufacturing

(LOM) – Other

Process description:

Liquid photopolymer in a vat is selectively cured by light-activated polymerization.

Materials:

Ceramic, photopolymer

Typical applications:

- Silicone hearing aids

- High surface finish prototypes

AM process variants – a selected overview

- Stereolithography (SLA) – Polymer

- Digital Light Processing (DLP) – Polymer

- Continuous Digital Light Processing (CLIP) – Polymer

- Lithography-based Ceramic – Ceramic Manufacturing (LCM) – Ceramic

The AM workflow

From virtual file to final part

The process of producing a part works in very different ways depending on the technology and the most important processes will be explained in more detail later in this course.

The overall process chain, covering the steps from a digital file to a finished product, is generally shared by all processes. There will, however, be some variations depending on the process and certain steps will require more effort whereas other steps will be more trivial for some processes.

Design & CAD

File Conversion

Parameter Definition

Machine Setup

Fabrication

Post Processing

Inspection & Testing

While a lot of of focus is usually put on the actual fabrication of the part, it often only accounts for a small portion of the overall process. It is thus important to be aware of all the different steps. We will give a quick overview of the different steps here.

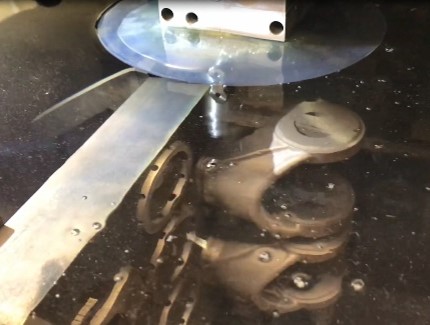

Videos of selected processes

Additive Manufacturing technologies in action

Below you can find a video explaining the 7 different process categories as well as brief videos of some of the most common Additive Manufacturing processes by hubs. A more detailed explanation of the different processes can be found in the two online learning programs Polymer Technologies and Metal Technologies.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSource: CanalDivulgación

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSource: hubs

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSource: hubs

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSource: hubs

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSource: Thomáš Vít

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information