Introduction to Part Identification

Introduction to Part Identification

Why selecting the right applications matters.

Selecting the right components for Additive Manufacturing is important – no matter at which stage you are. Whether you are just getting started or want to increase the use of AM in your area, part selection never loses its importance.

In this course we will guide you in the process of selecting the right components for AM.

What you will find in this section

Reasons for part identification

Why selecting the right applications matters

Selecting the right components for Additive Manufacturing is important – no matter at which stage you are in. Whether you are just getting started or want to increase the use of AM in your area, part selection never loses its importance. Some of the reasons making part identification so important are:

- Set realistic expectations on where AM has an influence on the company – and where not.

- Understand which technologies and materials to focus on depending on your applications

- Define your roadmap and strategy related to AM and identify key people that need to be trained.

Bottom-up vs. top-down

How to find the right applications

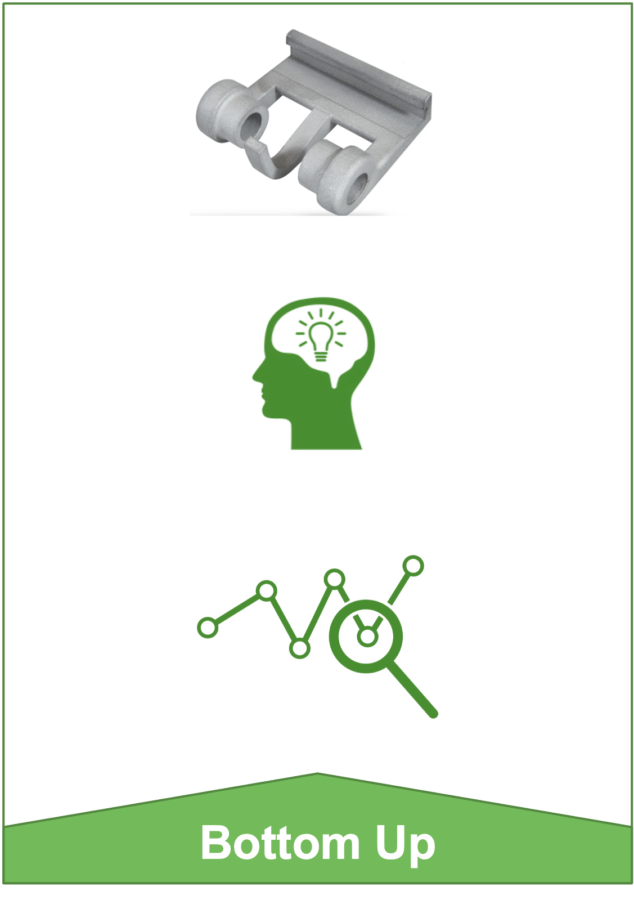

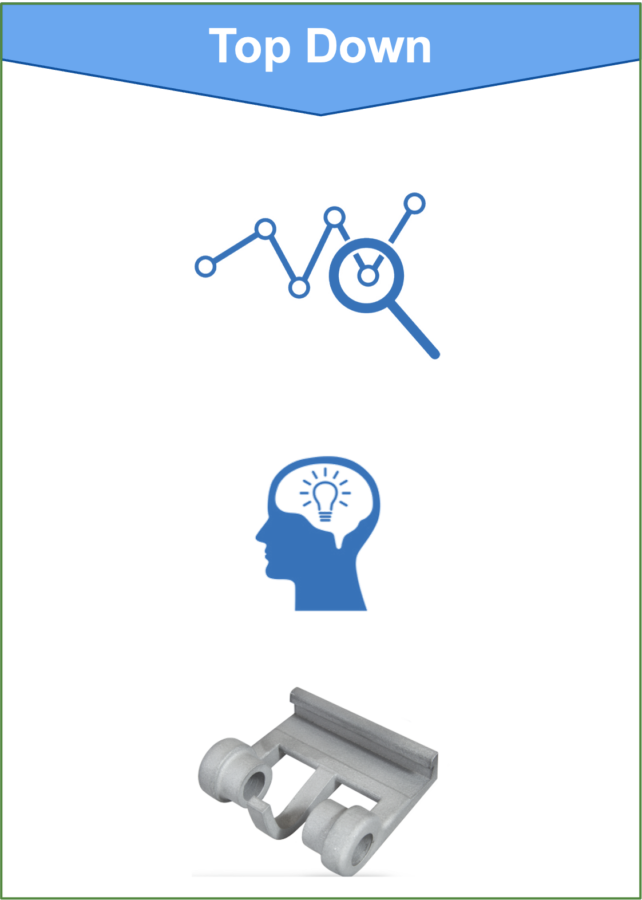

Generally speaking, there are two different approaches to part identification: bottom-up and top-down. We propose a bottom-up approach, also referred to as personalized approach, towards identifying the right components for Additive Manufacturing. There are more and more automated tools coming up that promise an automatic identification of suitable parts using a top-down approach by screening your ERP and CAD data. While this might work for some specific cases, such as identifying polymer spare parts, this will in most cases not lead to the identification of parts that add the most value to your company.

We believe that it is you and your colleagues that know your parts best and need to be involved in the part identification process. The part screening process should thus include people from design, sales, purchasing, quality, management and other disciplines to ensure a holistic perspective. In this online learning we will present you a simple methodology and information that will guide you in the process.

Bottom-up approach

Involvement of employees

Key employees are involved in the process early on

Identification based on experience

Different areas can be integrated into the part identification process

Easy data collection

Lower risk to make decisions based on outdated information

Time consuming training

Employees participating in part identification must be trained with AM skills

Possibly subjective

Evaluation and selection of parts depends on individuals

Screening limited to less parts

Bottom-up approach takes substantial time and is hard to scale

Top-down approach

Fast screening of many parts

Once the setup has been made, large amounts of parts can be screened automatically

Objective

Parts are objectively screened based on defined criteria

Difficult collection of relevant data

Hard to collect data from varying sources (SAP, CAD, technical drawings) in different formats (analog vs. digital)

Large amount of information

Huge amounts of data must be collected and verified

Software / search tool necessary

The top-down approach requires using software or search tool

Employees are not involved

A lack of involvement from employees can lead to resentment

The part identification process

Define your targets, screen suitable parts and realize your applications

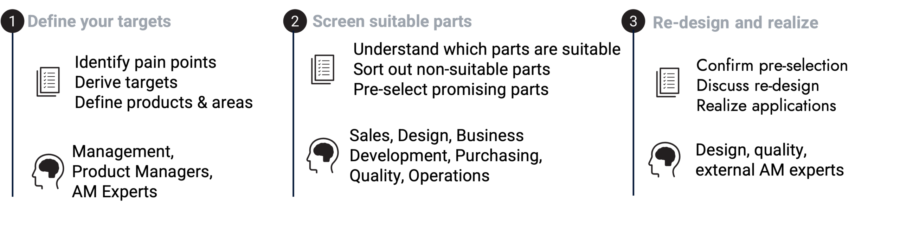

The part identification process proposed in this online learning is structured into three distinct phases:

- Definition of goals

- Screening of suitable parts

- Re-design and realiziation of identified components

In the following topic we will provide a quick overview of selected software tools that can support you in the part identification process.

We will then briefly cover the step Define your targets for the part identification process in the next module. The focus of this online learning will then be on step 2, the actual screening of parts.