Cold Spray

Cold Spray

High-speed impact bonding for AM

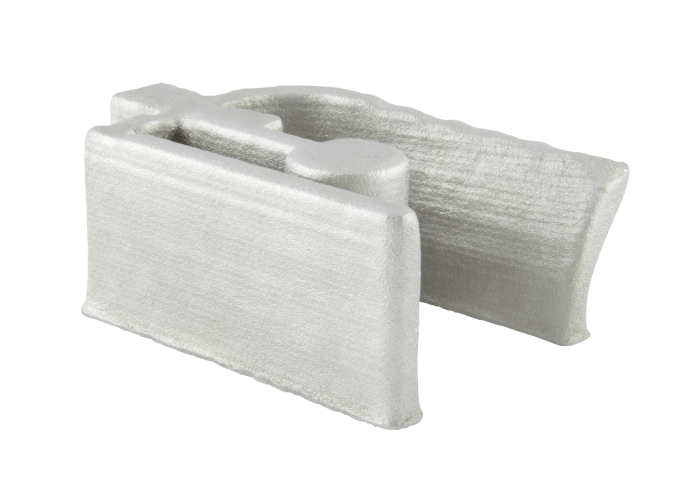

Coldspray is an Additive Manufacturing technology based on a traditional coating technology. Powder particles are bonded in solid state only by plastic deformation due to impact. This leads to extremely high productivity but the level of details and the data preparation are challenging.

Recent advancements have expanded its capabilities, enabling applications in aerospace, defense, and industrial repair. As Cold Spray continues to evolve, its unique combination of high-speed deposition and solid-state bonding distinguishes it from other AM processes, particularly for material combinations that are difficult to achieve with fusion-based methods.

What you will find in this section

Technology principle

How does Cold Spray work?

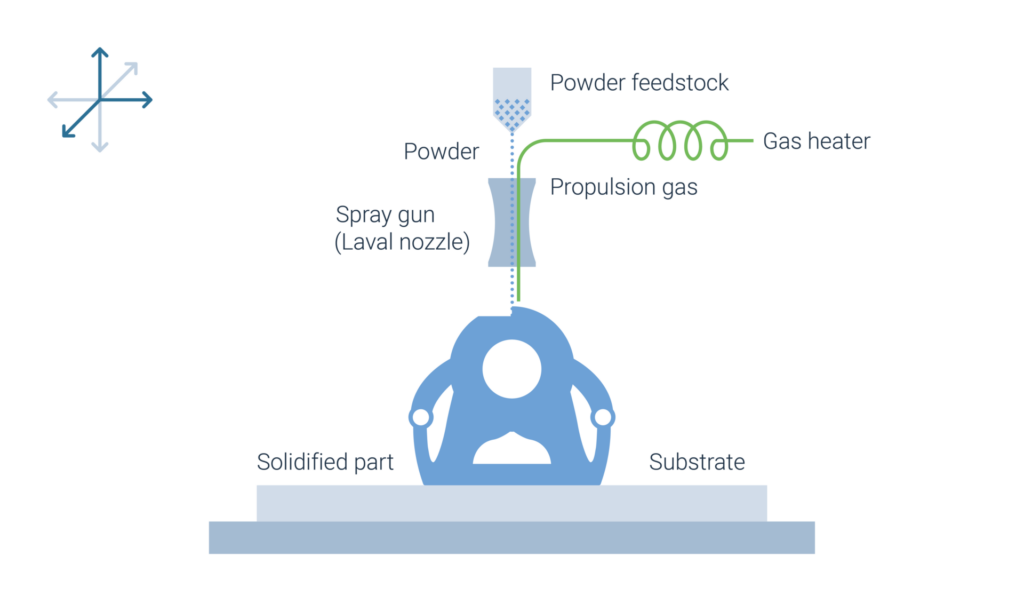

Coldspray is an Additive Manufacturing technology in which powder particles are bonded in solid state only by plastic deformation due to impact. The process uses the energy stored in high pressure compressed gas to accelerate fine powder particles to very high velocities. The kinetic energy of the accelerated powder is transformed to plastic deformation of the particles at impact on the substrate.

Compressed gas is fed via a heating unit to the gun and exits through the nozzle at very high velocity. From a feeder, powder is introduced into the high velocity gas jet. The powder particles are accelerated and directed on a substrate where they deform and bond to form a material layer. By moving the nozzle over the substrate repeatedly, a part can be built up layer by layer. The particles remain in solid state during the whole build job. Thus, the original powder chemistry is retained.

Coldspray machines can be distinguished into high pressure and low pressure spray systems. In high pressure systems, the compressed gas is divided into two streams. One stream passes through a heater and the other stream functions as a carrier gas for the powder particles. The carrier gas passes through the powder feeder, entraining the powder particles. Both gas streams are then mixed before entering a de Laval nozzle. Inside the nozzle the particle loaded gas expands and exits the nozzle with supersonic speed.

In a low pressure system, the powder is directly fed into the gas stream in the divergent section of the de Laval nozzle. Splitting the gas stream is not required. Hence, low pressure Coldspray systems are more flexible and cheaper in equipment and processing costs. Furthermore, the way how the relative motion between the part and the spray gun is realized can differ depending on the machine supplier.

Robot system with moving part

SPEE3D has developed a Coldspray machine in which the substrate is fixed to a robot arm with seven degrees of freedom. The spray gun is stationary while the substrate is moved relatively to it. The substrate can be tilted or moved translationally. By varying the speed with which the substrate passes the powder jet, the thickness of the deposited layer can be adjusted. The system allows high flexibility in part geometry due to the high freedom in motion of the substrate relative to the spray gun. However, part weight and size as well as spraying forces are limited by the strength and stiffness of the robot arm. Mostly very ductile materials such as aluminum and copper are processed with this set-up.

Gantry system with fixed part

A different approach in machine design has been created by the supplier TITOMIC. The substrate is fixed to a work table that can fulfill a translational movement. The spray gun is attached to a gantry via a robot arm. The stiffer set-up allows the use of larger more powerful spray guns and therefore the processability of less ductile materials.

Hybrid CNC machine-based system

HERMLE uses a similar approach for their Coldspray production service, integrating the spray gun into a multi-axis CNC system. The substrate is fixed to a rotation-tilt table while the spray gun has additional three degrees of freedom allowing for multi-dimensional relative movement. The set-up allows large and heavy parts of up to 400 kg to be build. The utilization of a high-power spray gun enables the processability of less ductile materials. Additionally, the system can utilize a milling spindle to machine the sprayed part in between single layers or after finishing the part. This enables high accuracies and a defined combination of multi-material. HERMLE uses this approach to build cooling channels, that are filled with a water-soluble material during spraying and cleared by a saline solution when the part is finished.

Development history

Parallel development by start-ups and traditional machine companies

The idea to accelerate particles in a gas jet to form coatings was already developed at the beginning of the 20th century. However, it took about 80 years until the technology was put into practical use at the Russian Academy of Science as a coating technology. Since then, steps were undertaken to develop the phenomenon into a practical industrial material coating process. As a result, the number of related patents and research publications has grown significantly. Around the year 2000 the process started to be employed for additive repair and fabrication of freeform structures and the first commercial Coldspray systems were introduced into the market.

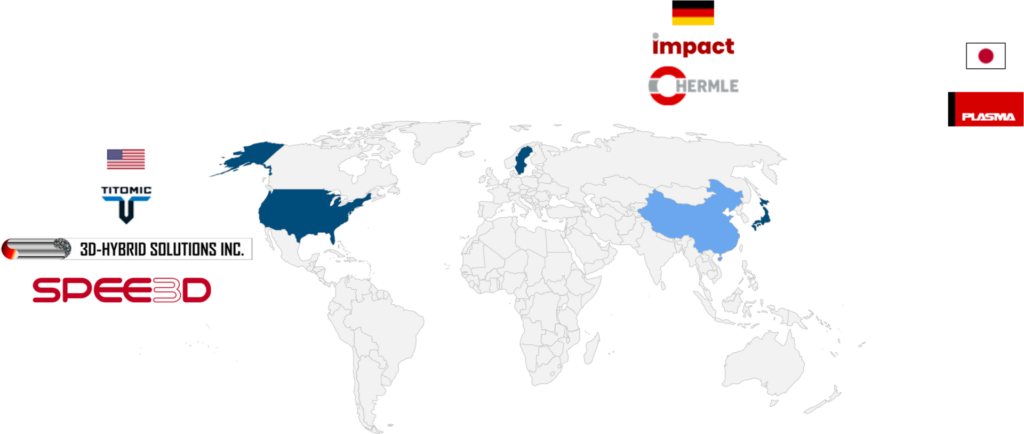

Dedicated systems solely focusing on Additive Manufacturing were recently introduced over the last couple of years. Today, several dedicated AM system suppliers for Coldspray technology exist, from which one, HERMLE as one of the traditional machine manufacturers, is using the systems only in-house for production services so far. SPEE3D and TITOMIC are startups which focus their activities on off the shelf systems and application specific systems.

Cold Spray Additive Manufacturing continues to advance slowly in its technological and industrial maturity. The compact, container-based solution by SPEED3D is successfully deployed to multiple armies and defense contractors. The promise of AM capabilities in combat zones for repair and spare part production is driving this development. However, many applications are still in the R&D phase and only very few systems are actually deployed in the field. While those systems manly use aluminum or copper alloys due to their lower power gun, TITOMIC and HERMLE target applications from titanium and steel, which they are able to process with their high-power gun and large stationary systems. Overall, Cold Spray still struggles to find more viable application and to position itself within the landscape of alternative AM technologies.

Supply chain

SPEE3D and TITOMIC are pushing into the market

Turn-key solutions of AM Coldspray technology is, at the moment, only offered by two Australian companies SPEE3D and TITOMIC. Where SPEE3D uses a compact system with a small spray gun for fast and intuitive production of small aluminum and copper parts, TITOMIC offers larger gantry systems with high power guns. A third machine manufacturer, HERMLE, developed a hybrid system based on their multi-axes CNC machine. However, at the moment these machines cannot be purchased. HERMLE only offers the production of parts as a service. Additionally, to these system suppliers, spray guns only can be purchased from different suppliers and combined with a manipulation system by the user.

Advantages and disadvantages

Balancing speed, material versatility, and geometric limitations

High deposition rates

Very high deposition rates (Titomic: up to 18 kg/h)

Exotic materials possible

“Non-weldable” materials and material combination possible

Low geometrical freedom

No possibility to build complex shapes

High material costs

Powder feed stock yields higher costs and quality assurance efforts than wire

Process video

The technology in action

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information