Sustainability of Additive Manufacturing

All Blog Articles Sustainability of Additive Manufacturing Is AM more sustainable compared to traditional manufacturing? Share article Additive Manufacturing is

Deutsche Bahn AG (DB AG) is the main German operator of transportation services and infrastructure. It offers mobility services, which include passenger rail and bus transportation, freight transportation, and railway infrastructure services. The company provides vehicle maintenance and security services. DB AG also offers conventional industrial energy products and develops and operates stations. The company also provides catering services, rail mobility management, communication technology products and operates global accounting shared service centres. It has operations in various countries across Europe, Asia-Pacific and North America. DB AG is headquartered in Berlin, Germany.

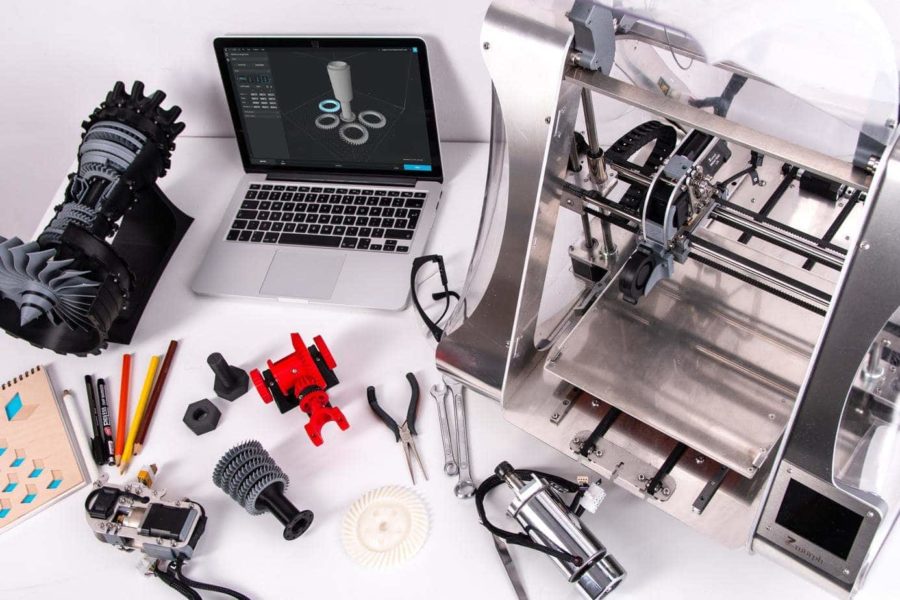

The 3D printing or Additive Manufacturing journey for Deutsche Bahn started in 2015. By 2023, the company has yet concluded 100.000 parts in 500 different applications using around 12 different AM technologies. The primary use cases are spare parts which can be found in various areas such as locomotives, wagons, infrastructure as well as train stations. 3D printing plays an important role at Deutsche Bahn as it enables much shorter and more cost-efficient repair cycles and increases the fleet and infrastructure availability. Trains are usually in operation for 30 years but in some cases even for over 50 years. After 15 years, spare parts can become more difficult to source and 3D Printing can successfully fill this gap. By digitalising the spare part inventory, the Deutsche Bahn now emerged as an early adopter and highly innovative company within the 3D printing industry. Besides spare parts, 3D printing is also strongly implemented at various DB sites for tools, jigs and fixtures. The technology saves time and money and sometimes even the operational performance is improved thus making the maintenance job on the shopfloor more efficient.

One of the most important learning for Deutsche Bahn is engagement. First, there is internal engagement with all relevant stakeholders. From engineering, quality management and maintenance staff to management. With specific applications that solve pressing problems, ensure vehicle availability, and may also save money, stakeholders can be convinced to further support the project or even get involved themselves. This starts with training and ends with internal, company wide marketing of success stories. While engineering and maintenance are triggered by applications that solve technical issues, management can be convinced by reduction of downtime during maintenance and cost savings, direct and throughout the lifecycle. Both areas are heavily addressed by the 3D printing applications which Deutsche Bahn has developed. The ideas for such applications often come from DB’s own employees who submit their printing suggestions, motivated by their own 3D Printing Competition.

But engagement also has an external component. Especially for companies, that cover multiple technologies and do not look at serial production of one single component, a vast network of partners can be vital for success. Especially exchanging with companies that have similar use cases can be extremely helpful. For Deutsche Bahn, those partners were found in other rail and mobility companies which led to the foundation of the Mobility goes Additive association. Topics that one single company can hardly cover such as materials, norms and standards are fast-tracked through this unique network in Europe.

Lesson 1

Get engaged - internally and externally

Many companies hire outside consultation to develop a 3D printing strategy long before their first actual parts are printed. At Deutsche Bahn, a “maker mentality” led to many initial use cases which tangibly helped to convince stakeholders and accelerate the adoption internally. Problem-solving use cases with a wow-effect in terms of size, quality, complexity and added value are more likely to convince both technology lovers as well as doubters. Even more important is that the initial use cases are not simply printed but carried through the whole process chain including testing and validation. Besides internal stakeholders, those proof-of-concept applications are last but not least important for external stakeholders as well as authorities.

Lesson 2

Proof the concepts and implement - impress lovers and doubters

The implementation journey of 3D printing as a clear change process for organisations is always a team challenge. If there is only one enthusiast, it is unlikely to become a success. A 3D printing team does not only consist of engineers but should also include team members on the maintenance shop floor on each site, quality managers, communication experts and procurement responsibles. Building this team is a key success factor. This means convincing and training of each team member, initiation of regular internal and external communication and the creation of a 3D printing team spirit with the ultimate goal to boost the efficiency of the company, reduce maintenance cost, and finally increase service quality and comfort for the end customer.

Learning 3

Shape a powerful team - you will love the ride!

3D printing has a very high potential in the spare parts industry. Deutsche Bahn has mastered to implement this technology through a long journey with the help of collaboration partners and by showing the full potential in over 500 specific use cases. This journey is still at its beginning. The ultimate aim is to create awareness for 3D printing possibilities within the whole company which will subsequently contribute to an increased vehicle availability and comfort for passengers plus higher internal efficiency of Deutsche Bahn.

All Blog Articles Sustainability of Additive Manufacturing Is AM more sustainable compared to traditional manufacturing? Share article Additive Manufacturing is

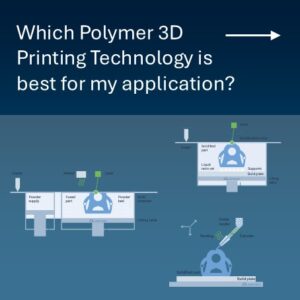

All Blog Articles Polymer Technology Selection Which Polymer 3D Printing Technology Is Best for Your Application? Share article Choosing the

All Blog Articles 3D Printing Surface Finish How to improve the surface finish of 3D printed parts Share article While

Would you like to further advance your 3D Printing success story? We learned that training a broad number of employees is key to increase the usage of 3D Printing in a company and to successfully launch new applications.

You can try out the AM Fundamentals course of the AMPOWER Academy free of charge

Understand the most important topics to get started with Additive Manufacturing

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from reCAPTCHA. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information