Barry-Wehmiller – Timothy Schniepp

“We are working to empower our development teams to effectively

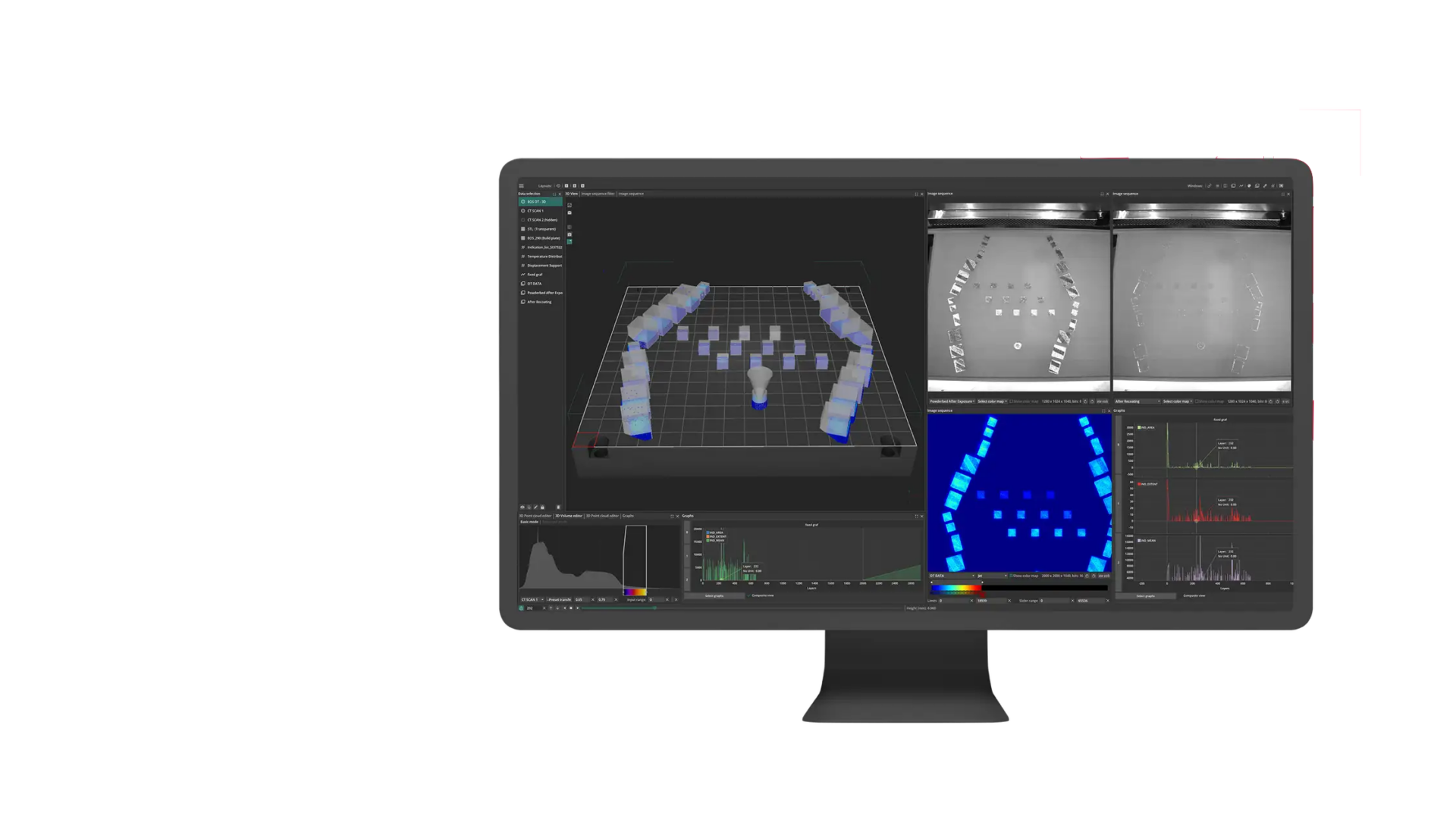

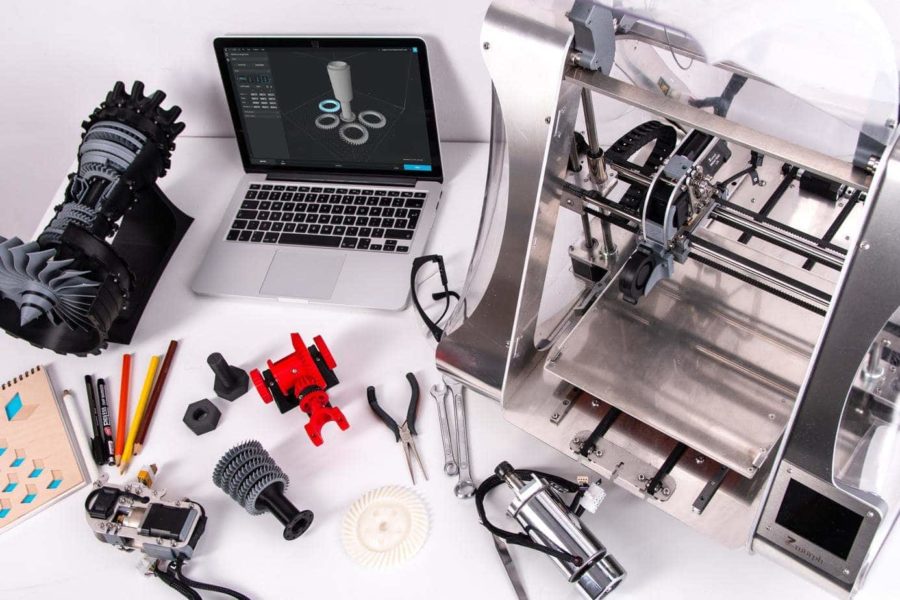

Navigating the world of 3D printing software can be overwhelming. Traditional CAD tools like Siemens NX and CATIA now come equipped with advanced 3D printing features, but there’s more to the picture! From design and optimization software like nTop to tools for Part Identification and Manufacturing Execution Systems (MES), the landscape is vast and ever expanding. Today there are over 100 companies offering 3D Printing software.

Choosing the right software is challenging, especially due to the overlap between different tools and the fact that interoperability isn’t always smooth. Initial integration can require significant effort and training.

Most standard CAD software is well suited for 3D printing but you may need to purchase additional modules. Dedicated solutions can further optimize results, such as for topology optimization, lattice structures, or process simulation.

This slideshow explores the essential software you need for successful 3D printing, highlighting how each tool contributes to the process.

Navigating the diverse landscape of 3D printing software presents a challenge for both newcomers and seasoned professionals alike. This ecosystem has evolved significantly, transitioning from traditional CAD tools like Siemens NX and Autodesk Fusion to a wide range of specialized software designed explicitly for 3D printing processes. These advancements cater to a wide range of industries, including aerospace, automotive, healthcare, and consumer goods, each with unique demands and opportunities in 3D printing technology.

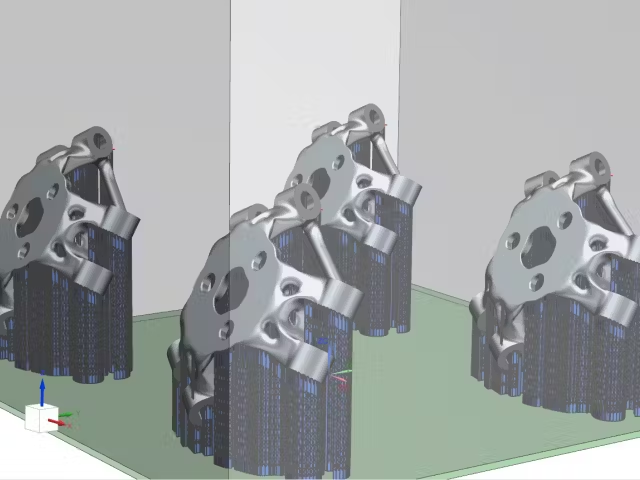

Established CAD Software such as Siemens NX and Autodesk Fusion, have adapted their existing Software to incorporate advanced features tailored for 3D printing. These platforms now integrate capabilities such as topology optimization, lattice structures, and support generation, enabling engineers to design complex geometries optimized for strength, weight reduction, and material efficiency. This evolution is particularly beneficial in industries like aerospace and automotive, where lightweight components can significantly enhance performance metrics such as fuel efficiency and structural integrity.

nTopology exemplifies a new wave of 3D printing software focused on generative design and optimization. Unlike traditional CAD tools that rely on predefined shapes, nTopology utilizes advanced algorithms to generate and refine intricate geometries based on functional requirements. This approach empowers engineers to explore design solutions that push the boundaries of what’s achievable with conventional manufacturing methods. By leveraging generative design, industries can achieve unparalleled levels of performance, customization, and innovation in product development.

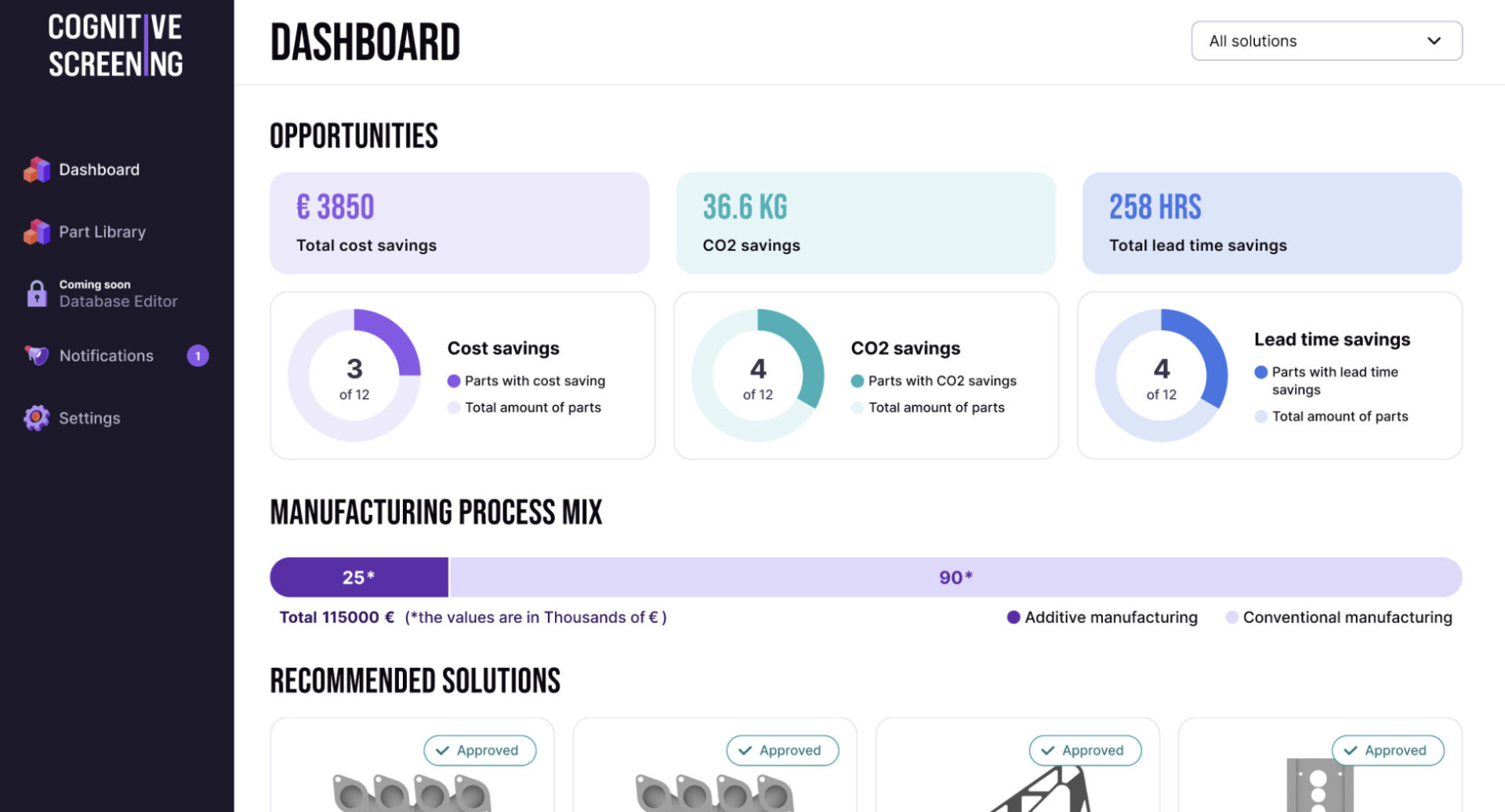

Part Identification software plays a crucial role in selecting components suitable for additive manufacturing based on geometry, material properties, and manufacturing constraints. These tools analyze design compatibility with available 3D printing technologies, minimizing errors and optimizing production workflows. Such capabilities are invaluable across all industries, especially when it comes to spare parts.

Manufacturing Execution Systems (MES) are pivotal in managing the additive manufacturing process comprehensively. By integrating production planning, scheduling, and real-time monitoring, MES software provides manufacturers with visibility into each print job’s status. This level of control ensures consistency, quality, and adherence to regulatory standards across batches of printed parts, critical in industries where precision and traceability are paramount.

Ensuring seamless data exchange between different software platforms—from design and simulation to printing and post-processing—is essential for maintaining efficiency and accuracy throughout the manufacturing process. Achieving interoperability often requires strategic planning and, at times, custom integration solutions tailored to an organization’s specific needs and existing infrastructure.

The initial integration of new software into existing workflows presents challenges, particularly in terms of training personnel and overcoming resistance to change within organizations. Effective training programs and management support are crucial in facilitating a smooth transition and maximizing the benefits of additive manufacturing technologies.

Future advancements in 3D printing software are poised to leverage artificial intelligence (AI) and machine learning to automate design optimization, predictive modeling, and real-time simulation. These technologies will enable faster iteration cycles, improved performance metrics, and enhanced customization capabilities in additive manufacturing.

In aerospace, advanced CAD tools and generative design software are revolutionizing the creation of lightweight components, enhancing efficiency and reducing environmental impact. Similarly, in healthcare, 3D printing software facilitates the production of personalized implants and prosthetics, improving patient outcomes and recovery times. MES software is streamlining production workflows in automotive manufacturing, optimizing resource utilization and ensuring compliance with stringent quality standards.

Navigating the landscape of 3D printing software requires a nuanced understanding of the capabilities, challenges, and strategic considerations involved. From traditional CAD platforms adapted for additive manufacturing to specialized tools like nTopology and MES systems, each software category plays a critical role in optimizing the additive manufacturing process across diverse industries.

By embracing advanced design, optimization, and production management tools, organizations can enhance productivity, reduce time-to-market, and foster innovation in their respective fields. However, achieving these benefits requires careful evaluation of factors such as interoperability, training needs, and long-term scalability.

As 3D printing software continues to evolve, driven by advancements in AI, machine learning, and real-time simulation, industry stakeholders can anticipate transformative improvements in design efficiency, material selection, and process control. By staying abreast of these innovations and investing in the right technologies, organizations can position themselves at the forefront of additive manufacturing, driving growth, efficiency, and competitive advantage in an increasingly dynamic global market.

“We are working to empower our development teams to effectively

All Blog Articles Sustainability of Additive Manufacturing Is AM more

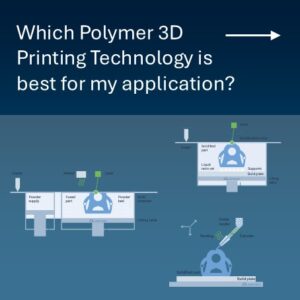

All Blog Articles Polymer Technology Selection Which Polymer 3D Printing

Would you like to further increase your 3D Printing knowledge?

You can try out the AM Fundamentals course of the AMPOWER Academy free of charge

Understand the most important topics to get started with Additive Manufacturing

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from reCAPTCHA. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information