Success Stories

Learn how companies become successful with 3D Printing

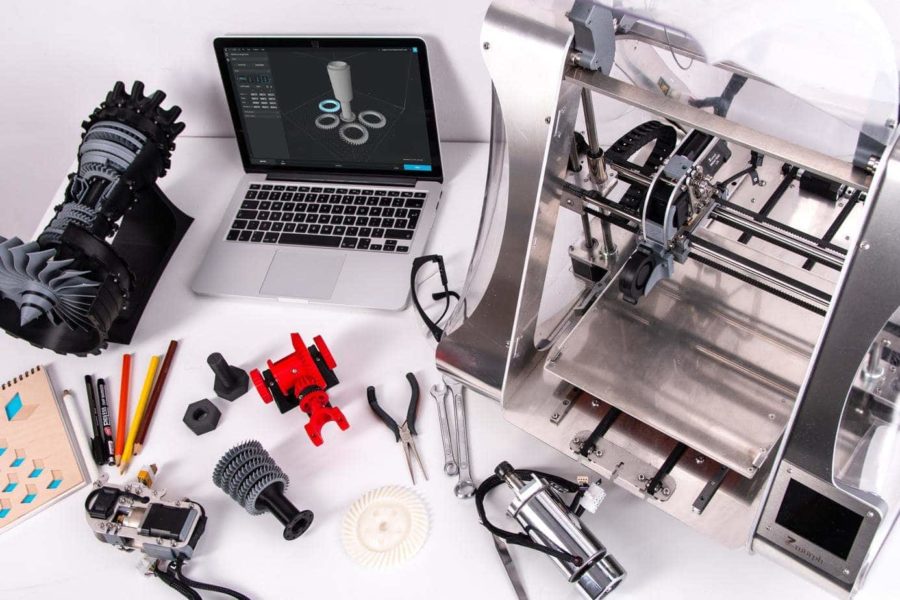

How to successfully implement 3D Printing into your organization

The successful implementation of 3D Printing in a company is a steady process involving different aspects such as training, lighthouse applications and building up a strong partner network. Over the past years companies across different industries have succeeded to implement the technology in their business. In this section we would like to share success stories of selected companies that can act as inspiration and guideline.

Training

Advance your 3D Printing success story

Would you like to further advance your 3D Printing success story? We learned that training a broad number of employees is key to increase the usage of the technology in a company and to successfully launch new applications. You can try out the AM Fundamentals course of the AMPOWER Academy free of charge.

Understand the most important topics to get started with Additive Manufacturing

How to get started

Draw inspiration from early adopters

Embracing 3D printing technology is a transformative journey unique to each organization. While integrating the technology for initial prototyping may not demand substantial investment or extensive strategy, advancing its use for producing spare parts or end-use components often requires a more comprehensive plan. Tailoring this journey to align with a company’s specific industry, product range, and customer dynamics is crucial. To help in navigating this progression, the success stories highlighted here serve as valuable resources. Whether you’re just beginning or further along in your journey, these narratives offer inspiration and guidance. They showcase how firms in similar industries have leveraged the technology effectively, yet also reveal insightful strategies from businesses in entirely different sectors. This exchange of experiences underlines the versatile potential of the technology across various market segments.

Training

The role of training in an organization

Crafting a clear strategy for 3D printing, while essential, is just the beginning; the real challenge lies in its effective implementation. This process demands a holistic approach, involving support from top-level management, selecting appropriate technologies, and fostering strategic partnerships. However, at the core of every successful technology integration is a skilled workforce. This means not only recruiting new talent with expertise in 3D printing but also upskilling existing employees.

The skills gap is frequently cited as a major obstacle in adopting the technology for many organizations. A significant bottleneck is often found within the design department. If parts are not optimally designed for 3D printing, the technology’s potential is significantly undermined. Therefore, it’s vital to equip designers with a foundational understanding of various technologies, alongside advanced knowledge specific to their needs. Beyond training designers, it’s equally important to educate employees across other departments, ensuring a comprehensive understanding of its impact. This holistic approach should include staff in sales, customer support, quality control, management, and purchasing.

By addressing these areas, companies can leverage the full potential of 3D printing, transforming it from a mere technological addition into a robust, integrated component of their business strategy and operations.