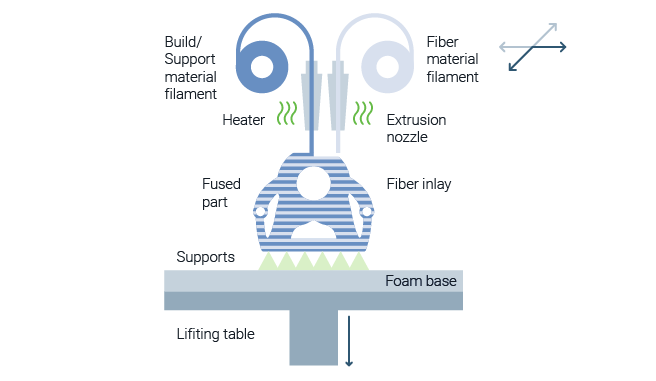

Continuous Fiber Material Extrusion

Material Extrusion printing with increased strength

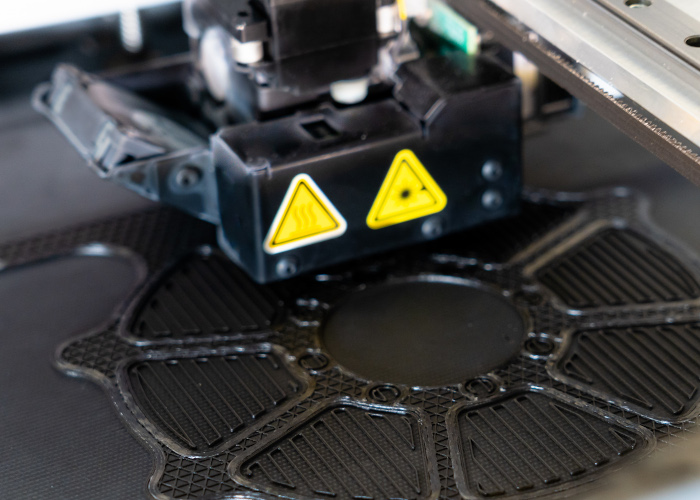

Continuous Fiber Material Extrusion is a modification of Filament Based Material Extrusion. In addition to the use of thermoplastic material a continuous fiber is used to increase the mechanical properties of the produced part. This technology nowadays supplied by several suppliers such as MARKFORGED, ANISOPRINT and DESKTOP METAL.

The process is similar to the conventional Filament Based Material Extrusion process. Thermoplastic material in form of filament is heated until the material is molten and then continuously pushed through an extrusion nozzle. Within the Continuous Fiber Material Extrusion, a continuous fiber might be added to the filament and is embedded in the generated part. The fiber is mainly used to improve the mechanical properties of the part and can selectively be extruded to improve properties in heavy loaded areas of the part.

Read more about this topic in the Polymer Technologies Course.