Barry-Wehmiller – Timothy Schniepp

“We are working to empower our development teams to effectively implement Additive Manufacturing, allowing us to save time and cut

Cost per part in AM – How much does it cost to print a part?

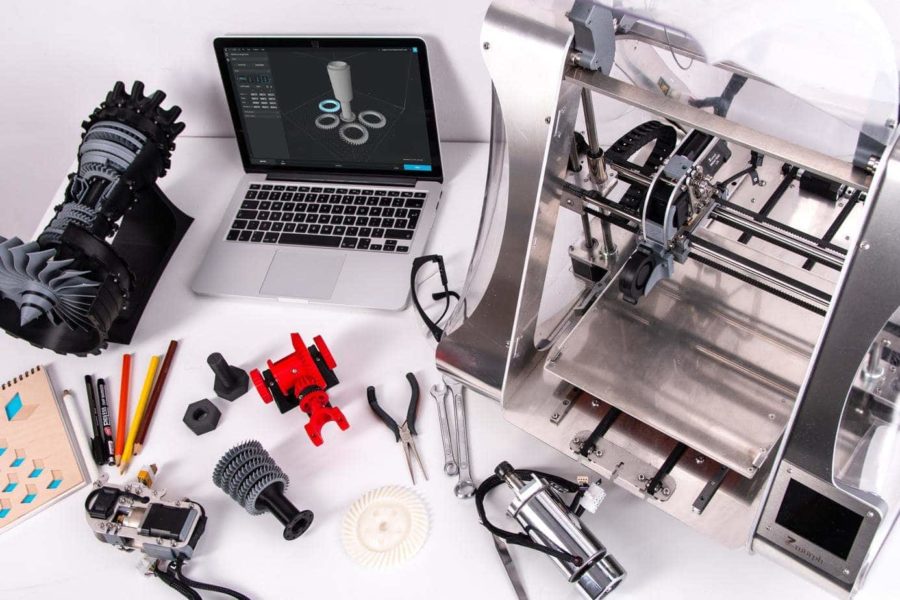

3D Printing has developed from a technology that is mainly used for prototyping to a viable manufacturing technology for end-use parts. Understanding how the costs for printing a part compare with the costs for conventional manufacturing technologies is thus gaining increasing importance.

Understanding the real costs for printing a part is not as straight-forward as it may sound. Even once the best combination of technology, materials and printing parameters has been found, arriving at a definitive number can be challenging. When comparing the costs for sourcing a part from external suppliers, we observe a big price spread.

In the rapidly evolving field of Additive Manufacturing (AM), understanding the cost is crucial for businesses aiming to leverage this technology effectively. Additive Manufacturing, often referred to as 3D printing, has transitioned from a prototyping tool to a viable manufacturing solution for end-use parts. However, determining the cost per part can be complex, as it depends on various factors, including whether the part is produced internally or by an external supplier. This blog post explores the intricacies of cost per part in Additive Manufacturing, highlighting the factors that influence costs and the potential for both direct and indirect savings over the lifecycle of parts.

3D Printing has evolved significantly from its early days as a tool for creating prototypes. Today, it is a powerful manufacturing technology used across various industries, from aerospace to healthcare. Understanding how the costs of printing a part compare with those of conventional manufacturing technologies is increasingly important for businesses considering the switch to AM.

The choice of technology and materials is a primary determinant of the cost per part in Additive Manufacturing. Different 3D printing technologies, such as Stereolithography (SLA), Powder Bed Fusion (PBF), and Material Extrusion (ME), have varying cost structures and capabilities. Similarly, the materials used—ranging from polymers to metals—affect both the cost and performance of the printed part.

Process parameters, such as layer height, print speed, and post-processing requirements, significantly influence the part cost. For instance, finer layer heights result in higher resolution prints but take longer to produce, increasing machine costs.

Production volume also plays a crucial role. While small-batch production may have higher per-unit costs due to setup and calibration efforts, larger volumes benefit from economies of scale. Bulk production can reduce one-time costs for qualification and data preparation and increase efficiency, lowering the overall cost per part.

When comparing the costs of sourcing a part from external suppliers versus producing it internally, a significant price spread can often be observed. External suppliers may offer lower per-unit costs due to economies of scale and advanced production capabilities. However, internal production provides greater control over the design and manufacturing process, which can be crucial for maintaining quality and meeting specific requirements.

Direct cost savings in Additive Manufacturing can be achieved through various means, resulting from less material usage, less manufacturing operations and less complex processes. Unlike traditional manufacturing, which often involves material removal processes that generate waste, AM builds parts layer by layer, only adding material where needed. This brings the potential to save costs especially for complex applications.

Beyond the direct costs, Additive Manufacturing can lead to substantial indirect cost savings over the lifetime of the parts. These savings can come from several areas, including enhanced product performance, reduced maintenance, and improved supply chain efficiency.

For instance, lightweight designs enabled by AM can lead to energy savings in aerospace and automotive applications. Custom medical implants created through AM can improve patient outcomes and reduce healthcare costs. Furthermore, AM allows for on-demand production, reducing the need for inventory storage and lowering supply chain costs.

One of the most significant benefits of Additive Manufacturing is the freedom of design it offers. This design freedom allows for the optimization of parts to reduce costs while enhancing functionality. By leveraging design techniques such as topology optimization and lattice structures, engineers can create parts that are not only lightweight and strong but also cost-effective to produce.

A comprehensive cost-benefit analysis is essential for making informed decisions about Additive Manufacturing. This analysis should consider both direct and indirect costs, including material expenses, production time, labor, and potential savings in product performance and maintenance.

Choosing the appropriate AM technology and material for your specific application is crucial for optimizing costs. Factors to consider include the mechanical properties required, the complexity of the design, and the production volume. Consulting with AM experts and conducting material tests can help identify the best options.

Design for Additive Manufacturing (DfAM) principles can significantly enhance the cost-efficiency of 3D printed parts. These principles involve designing parts specifically for the capabilities and constraints of AM, such as minimizing support structures, optimizing build orientation, and reducing material usage. By incorporating DfAM principles, companies can achieve substantial cost savings and improve the overall quality of their printed parts.

Maintaining quality and consistency in 3D printed parts is a common challenge. Implementing robust quality control measures, such as in-situ monitoring and post-production testing, is essential to ensure that parts meet the required standards. Investing in advanced inspection technologies, like non-destructive testing (NDT), can help verify the integrity of printed components.

Scaling up Additive Manufacturing for mass production involves addressing challenges related to print speed, consistency, and cost-effectiveness. Strategies such as utilizing multiple printers, optimizing print parameters, and automating post-processing workflows can enhance scalability. Developing standardized procedures and adopting automation solutions can further improve production efficiency and reduce costs.

The future of Additive Manufacturing is bright, with continuous innovations poised to expand its capabilities and reduce costs. Advances in materials science, printing technologies, and design software are set to push the boundaries of what is possible with AM. Emerging technologies, such as multi-material printing, bioprinting, and large-scale AM, hold the potential to revolutionize various industries.

As the benefits of Additive Manufacturing become more widely recognized, its adoption across industries is expected to grow. Companies that embrace the freedom of design and invest in AM technologies will be well-positioned to lead in their respective fields. By fostering a culture of innovation and continuous improvement, businesses can unlock new opportunities and drive competitive advantage.

Determining the cost of 3D printing a part involves careful consideration of various factors, including technology, materials, process parameters, and production volume. By leveraging the freedom of design that Additive Manufacturing offers, companies can optimize parts for cost-efficiency and performance, achieving both direct and indirect cost savings over the lifetime of the parts.

For professionals and industrial companies looking to improve their knowledge and capabilities in Additive Manufacturing, understanding and applying the principles discussed in this article is essential. Dive deeper into the world of 3D printing and explore the endless possibilities that the freedom of design in Additive Manufacturing presents.

“We are working to empower our development teams to effectively implement Additive Manufacturing, allowing us to save time and cut

All Blog Articles Sustainability of Additive Manufacturing Is AM more sustainable compared to traditional manufacturing? Share article Additive Manufacturing is

All Blog Articles Polymer Technology Selection Which Polymer 3D Printing Technology Is Best for Your Application? Share article Choosing the

Would you like to further increase your 3D Printing knowledge?

You can try out the AM Fundamentals course of the AMPOWER Academy free of charge

Understand the most important topics to get started with Additive Manufacturing

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from reCAPTCHA. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information