Additive Manufacturing design

Additive Manufacturing - a designers dream come true?!?

Additive Manufacturing offers a high degree of design freedom that is not possible with traditional manufacturing techniques such as machining or casting. While AM bring a set of advantages such as tool-less production in low quantities that can be realized without redesigning the part, the full potential of the technology can only be realized when redesigning parts.

This freedom requires designers to rethink the way they learned to design for traditional manufacturing techniques.

What you will find in this section

The AM Design Process

Rethink the product before re-designing it

The conventional design process needs to be at least partially adapted in order to get the most out of Additive Manufacturing. The key point is to re-think the product and its function before diving too deep into design guidelines and creating the actual file.

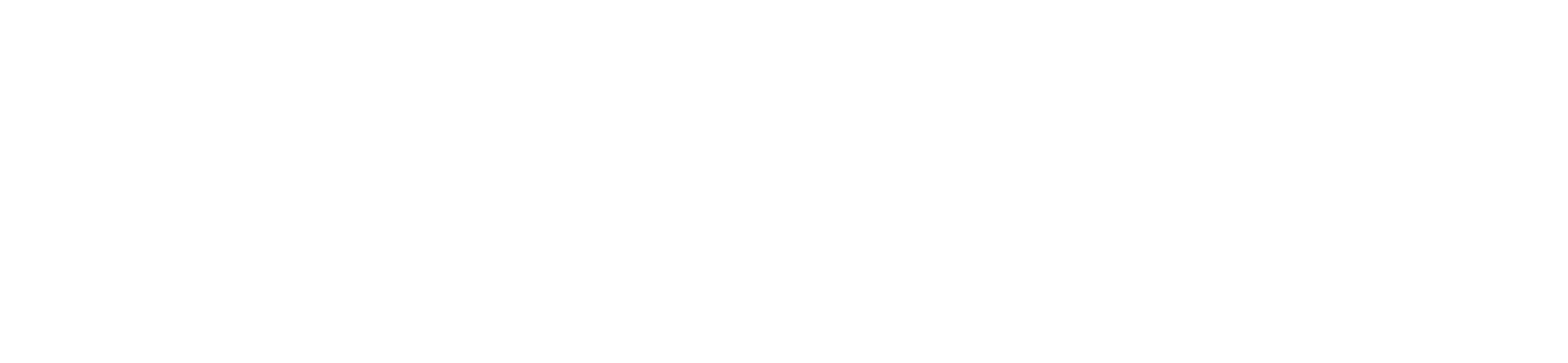

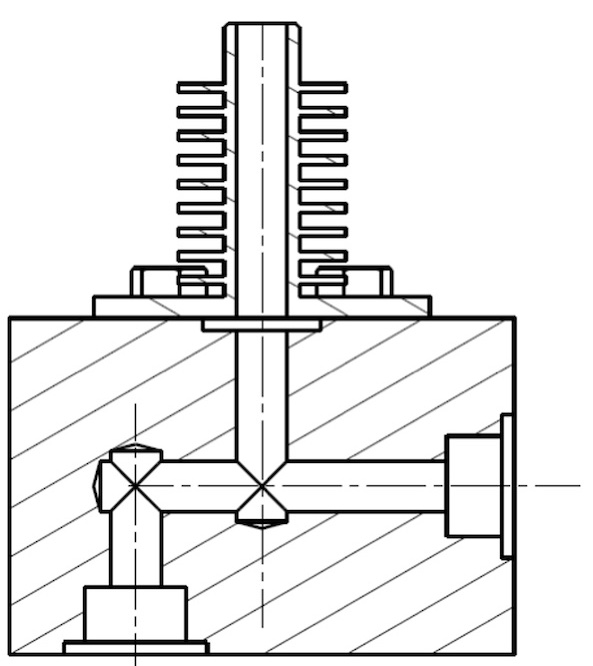

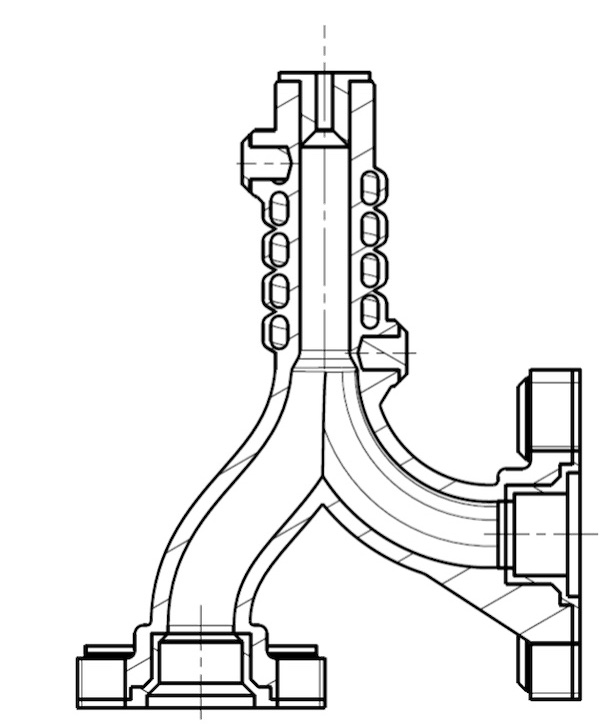

We have summarized the main steps of the AM design process below. Each step is explained using the example of the following valve block that is redesigned with the goal to optimize the cooling and to replace it by an active cooling element.

Original design / part idea

The AM design process can both be applied to existing designs or ideas and concepts for new parts.

1Analyze functionality and integration potential

The starting point of the AM design process should always be the functionality of the part.

- What are you trying to achieve with this application?

- How would the part look like if there were absolutely no design restrictions?

- Which parts are connected to the application and can they be integrated into the design?

Create new solutions and designs

Creating new solutions and ideas is probably the most important step.

- Use creative design methods.e.g. Design Thinking, biomimicry).

- Do not judge crazy or bold design suggestions.

- Build upon the concepts of others.

Define non-design areas

Define the boundary conditions and areas of the part that are fixed and cannot be changed.

4Define AM part orientation

Defining the orientation is the first step when it comes to the actual design of the AM part. The orientation will influence all other design features.

5Design AM part geometry

Once the orientation is fixed and non-design areas are defined, the actual AM part geometry needs to be designed.

Technology-specific guidelines will help you during this phase.

6Add post processing offsets

Define which areas will require post processing and add machining allowances to the surfaces.

This usually requires having a discussion with the machining company.

7Old design

- 7 parts

- 1 Assembly step

- 746 g mass

New design

- 1 part

- 0 assembly steps

- 117 g mass

- Reduced flow resistance

- Active cooling integrated

Integral design concepts

Integrate surrounding parts and functions

Using integral design concepts is one of the fundamental approaches when designing for Additive Manufacturing. Understanding the entire system and then integrating as much into the design at hand often leads to impressive reductions in complexity, assembly time, manufacturing operations and ultimately cost.

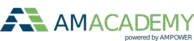

The A380 fuel connector study that can be seen on the left is a good example for integral design. In this case, 14 conventional parts have been integrated into 1, which led to a reduction in manufacturing operations from 18 to 5. The ultimate led to 50% lower cost of the new design compared to the conventionally produced parts.

Another great example is the Advanced Turboprop (ATP) engine from GENERAL ELECTRIC (GE). GE completely rethought the entire design of the ATP engine with AM in mind and could achieve some impressive results:

- Reduction of over 800 individual components into 11 AM parts

- 35% of total assembly manufactured

- Significantly improved fuel efficiency.

Another great way for Additive Manufacturing to add value is by integrating functionality into components. Typical examples for this include the introduction of heating or cooling channels or filters into parts.

Topology Optimization

Part optimization according to load cases

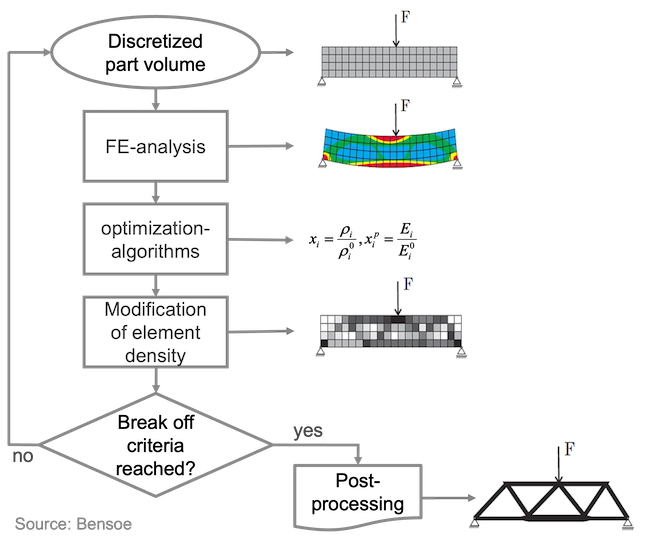

Topology optimisation (TO) is a computer-based design process that uses mathematical algorithms to optimise the shape and material distribution of a structure or product, with the goal of improving its performance characteristics. While TO is not directly linked to AM, the design freedom of AM allows for the direct production of the complex shapes that are usually the outcome of the optimization. The principle of only using material wherever necessary additionally saves production cost for since with AM the costs are usually driven by the part volume.

The TO process is described on a high level on the right side and demonstrated using a bracket in the video below.

Demonstration video of the topology optimization process. Video Source: CAESS ProTOp

Biomimetics

Design inspiration from nature

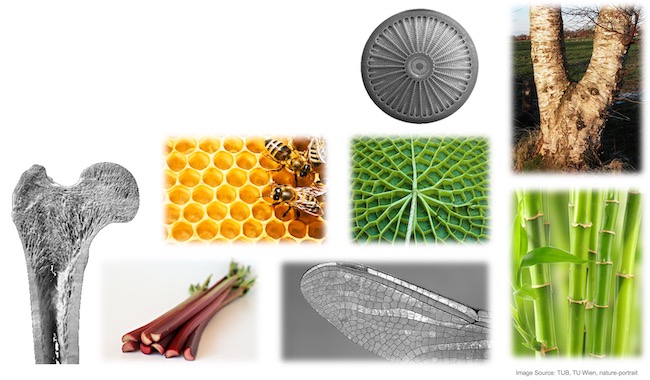

Biomimetics, also known as biomimicry, is the study of nature’s design and function to develop new materials, products, and technologies that solve human problems.

The benefits of drawing inspiration from nature are manifold, such as optimized material efficiency, homogenization of stresses, reduction of peak stresses and increased bending stiffness. Similar to Topology Optimization, this concept is not directly linked to AM but the design freedom makes it a good fit.