Powder Feedstock Market

Understanding the Powder Feedstock Landscape

Metal powders are the most commonly used feedstock in Additive Manufacturing.

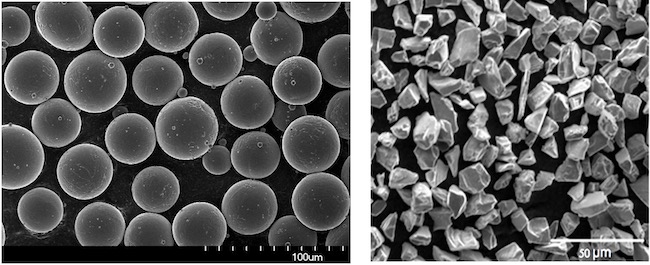

While the same powder production methods such as gas or water atomization are used across different AM technologies, the specific powder requirements can vary significantly depending on the process. In particular, particle size and morphology play a critical role in determining whether a powder is suitable for a given application.

In this section, you’ll learn which alloys are typically used in metal AM, how powder characteristics like size, shape, and production method influence performance, and how requirements differ between processes such as Powder Bed Fusion, Directed Energy Deposition, and Cold Spray. You’ll also see why some technologies allow for greater flexibility and cost efficiency in powder selection.

What you will learn in this section

Materials for Laser Powder DED

Which alloys are commonly used in DED and why they are suitable for large parts and repairs.

Materials for Cold Spray

Which ductile metals work with Cold Spray and what powder properties are required.

Powder Production and Requirements

How metal powders are made and what makes them suitable for DED and Cold Spray.

What you will find in this section

Laser ED Materials

Common Alloys for Powder Laser ED

- Steel

- Nickel Based Alloys

- Titanium Alloys

- Cobalt Alloys

- Aluminum Alloys

Stainless Steel 316L (1.4404):

Austenitic stainless steel commonly used in chemical, marine, and food industries. Excellent corrosion resistance and processability make it a standard for DED.

Stainless Steel 17-4PH (1.4542):

A precipitation-hardening martensitic steel offering high strength and good corrosion resistance. Used in aerospace, energy, and tooling applications.

Maraging Steel 18Ni300 (1.2709):

Ultra-high strength steel used in tooling, injection molding, and die casting. Marging Steel in DED is possible but not yet widely used.

Inconel 718 (2.4668):

The most widely used superalloy in DED. Combines high strength, oxidation resistance, and creep resistance. Common in turbine, aerospace, and energy sectors.

Inconel 625:

Preferred for corrosive environments such as chemical plants or offshore applications.

Titanium alloys are possible, but challenging to implement due to shielding of the process.

Ti-6Al-4V (Grade 5):

Lightweight, strong, and biocompatible. Widely used in aerospace, medical, and marine sectors for structural components and repairs.

Cobalt alloys possible but not widely available for Powder Feed Laser Deposition.

Cobalt-Chromium (CoCr):

Known for wear resistance, corrosion resistance, and biocompatibility. Used in turbine components, dental applications, and orthopedic implants.

AlSi10Mg:

Occasionally used in DED , though aluminum is less commonly processed than other metals since shielding the build process from oxygen is difficult to implement.

Other Al alloys:

Ongoing development is focused on improving weldability and reducing hot cracking.

Cold Spray Materials

Common Alloys for Cold Spray

Cold Spray is limited to ductile materials with fine particle sizes (typically 5–45 µm). The process is especially suitable for corrosion protection, electrical conductivity, and structural repair. While many metals are technically feasible, only a subset is widely used in practice.

- Steel

- Nickel Based Alloys

- Titanium Alloys

- Copper and Bronze

- Aluminium Alloys

Stainless Steel

(e.g., 316L):

Suitable for protective coatings in marine, chemical, and infrastructure settings.

Maraging Steel:

Technically feasible, with limited use in tooling repairs.

Possible but not widely used; relevant for chemical and high-temperature coatings.

Titanium Alloys (e.g., Ti-6Al-4V)

Applied in biomedical, aerospace, and defense for durable, corrosion-resistant coatings.

Copper and Alloys (e.g., Cu, CuCrZr, Bronze)

Used in thermal and electrical applications, including bus bars, induction coils, and heat exchangers.

Aluminum and Alloys (e.g., 6061, 5083, 7075):

Common for corrosion-resistant coatings, lightweight repairs, and aerospace/automotive applications.

Powder production processs

Powder Production for DED and Cold Spray

Powder is a key feedstock in many Additive Manufacturing processes, including Powder Directed Energy Deposition (DED) and Cold Spray. While overall powder consumption in AM continues to grow, it remains relatively low compared to conventional feedstocks such as bar stock or wire. In general, powder materials are more expensive per kilogram than traditional bulk materials due to specialized production methods like gas atomization.

However, Powder DED benefits from a broader acceptable particle size distribution compared to powder bed technologies like Laser Powder Bed Fusion (L-PBF). As a result, the cost per kilogram of powder used in DED is typically lower than in L-PBF.

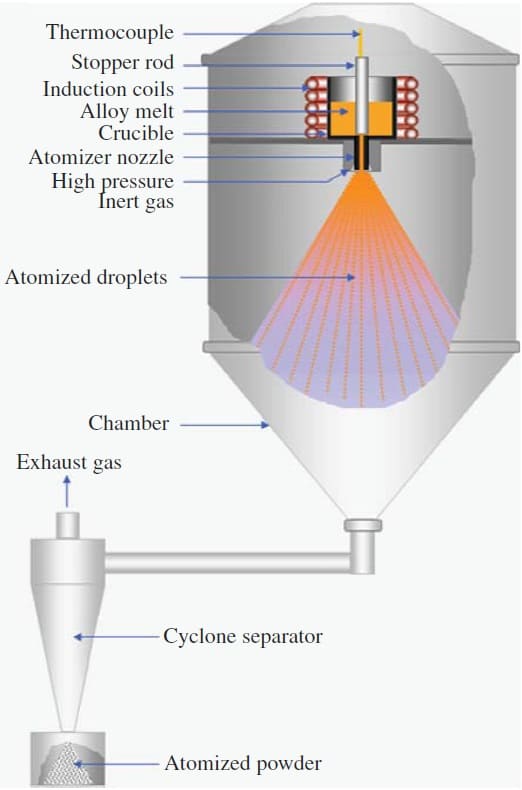

For the production of metal powders, gas atomization is the most common method. Another more cost-effective solution which however results in less ideal powder particles is water atomization. In both cases, molten metal is poured into an atomization chamber and broken into fine droplets using high-speed jets of gas or water. These droplets cool and solidify into metal powder. After the actual atomization process, the particles need to be sieved into the right particle fraction to ensure an optimal flow and high density during part production.

The main difference between the two atomization techniques lies in particle shape and surface quality. While gas atomization leads to more spherical powders without satellites, the high gas consumption leads to a higher price compared to water atomization.

Gas Atomization

Gas atomization results in spherical powders with good flowability, which are ideal for processes requiring consistent and stable powder delivery, such as Laser Powder DED.

Water Atomization

Water atomization produces irregularly shaped powders, which are less expensive but have lower flowability. While unsuitable for layer-based processes like PBF, they can be used in some DED and Cold Spray applications where cost efficiency is prioritized over perfect flow.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationPowder requirements Laser ED

Coarser PSD, Lower Cost, Greater Flexibility

Laser Powder ED systems typically use metal powders with a coarser particle size distribution (PSD) than those used in Powder Bed Fusion. The typical PSD range is 30–150 µm, allowing for higher material feed rates and more efficient deposition. Because DED does not require layer spreading like L-PBF, it can tolerate a broader PSD and slight irregularities in shape, resulting in lower powder cost and wider supplier options.

Particle SIze Distribution (PSD)

Particle Size Distribution (PSD)

Production Method

Production method

Shape and flowability

Shape and flowability

Capture efficiency

Capture efficiency

Powder requirements Cold Spray

Focus on Kinetics, Not Melting

Cold Spray is a solid-state additive and repair process, where particles are accelerated at supersonic speeds and plastically deform upon impact with a substrate. Because Cold Spray does not involve melting, sintering behavior and flow in a melt pool are irrelevant, shifting the focus to aerodynamics, particle velocity, and bonding behavior.