AM Academy

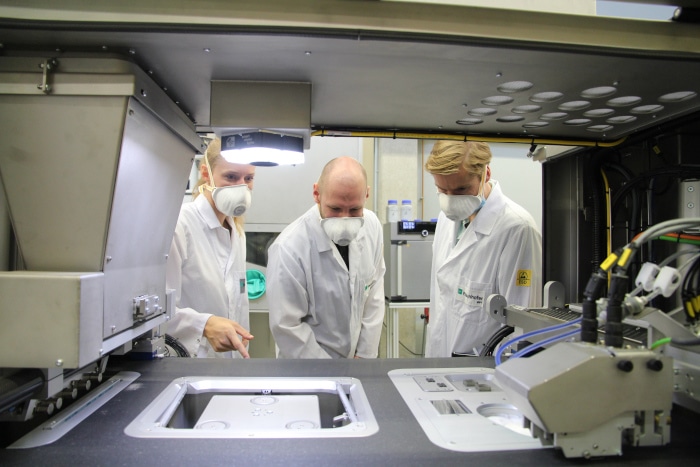

Hands-on Trainings

Unlock Advanced AM Expertise with hands-on workshops and live trainings.

Hands-on trainings and workshops provide an excellent opportunity to apply theoretical knowledge while engaging in discussions with experts and peers. Our customizable Live Trainings combine theoretical and practical modules tailored to your needs and can seamlessly integrate with our online learning courses. Delivered by industry experts, these trainings can be conducted in-person at your facility or online for maximum flexibility.

1000

engineers have already been trained by the trainers

100%

of the participants rate the training as good or very good

50

years of experience of the trainers in Additive Manufacturing

Why choose the Live Training Sessions?

- Expert-Led Sessions with Industry Professionals

- Customizable Content Tailored to Your Needs

- Flexible Delivery: Online or In-Person

- Use of best in class software and Tools

- For beginners, advanced and experts

Our Live Training Sessions offer practical, expert-led learning in Additive Manufacturing—online or in person. Tailored to your goals, they focus on real-world application and hands-on skills.

Designed to complement our online modules, these sessions help participants move from theory to implementation—whether you’re just starting with AM or advancing existing capabilities.

Training Types

Basic Training

The BASIC training Additive Manufacturing teaches the fundamentals of the technology, from understanding the process and material properties to the process chain and design guidelines. The training is the basis for a screening for Additive Manufacturing. The BASIC training is an alternative to the online learning courses.

Part Identification

Part Identification is a structured project to assess parts for AM technologies. It provides fundamental knowledge, software-supported screenings, and application evaluations. Participants analyze applications, assess 3D models, and explore cost, time, and CO2 savings. The project delivers concrete outcomes, including a facility assessment and a detailed summary to support business decisions.

Custom Training

Flexible, tailored training combining theory, hands-on practice, and company-specific content. Delivered online or in-person by experts for small to medium-sized groups.

Custom Training

Flexible format: ”Mix and Match” of existing modules, combination with e-learning and company-specific modules

- Delivered online or in-person by expert trainers

- Combination of Theory and Practice modules

Knowledge transfer through presentation

- Group size: 10-15 participants

- Location: In-person or online

Hands-on exercises applying theory, good follow-up for online learning or theory

- Group size: 8-10 participants

- Location: In-person recommended

Theory Module Overview

| Module Name | Content |

|---|---|

| AM Introduction | Principle of AM, Advantages & Challenges, Industries & History, Potential |

| Technology Overview | Technology classification, working principles, materials and applications of polymer & Metal Technologies |

| L-PBF Deep-Dive | Process chain, machine principle, process parameters, material properties |

| E-PBF Deep-Dive | Process chain, machine principle, process parameters, material properties |

| Sinter-Based AM Deep-Dive | Process chain, technologies, sintering, debinding, process parameters, material properties |

| Directed Energy Deposition Deep-Dive | Process chain, powder and wire technologies, machine principle, process parameters, material properties |

| Process Chain PBF Metal | Process chain overview including Data preparation, printing and post processing |

| Mechanical Properties PBF Metal | Material characteristics, microstructure, mechanical properties |

| Design for AM Theory | AM Design Process, Design guidelines, design to cost |

| Business Case & Part Identification | Business Case Models & Part Criteria, Top-down vs. Bottom-up screening |

| AM Cost Calculation | General cost considerations, Cost calculation PBF, sinter-based AM, Make or Buy |

| Software Landscape and digital design | Overview of available AM-related software and their functionality, process chain from digital model to final part |

Workshop Module Overview

| Module Name | Content |

|---|---|

| Technology Sorting | Single or group exercise, sort technologies by characteristics (e.g. mechanical properties, productivity, cost per volume) |

| Technology Identification | Select most suitable technology for sample applications, including advantages & process chain |

| Quick Re-Design | Re-design a sample part (fluid-guiding application) on paper |

| Quick Support Design | Orient sample parts and propose support structures on paper |

| Part Identification | Discuss suitability of participant applications for AM, |

| Risk Identification | Identify risks along the AM process, define mitigation actions |

Binder Jetting Training hands-on

Metal Binder Jetting is one of the most promising metal 3D Printing technologies with a high potential for low cost and high-volume digital manufacturing. However, the complete process chain of Binder Jetting is highly complex and the supply chain is still developing. AMPOWER created a unique binder jetting training course in cooperation with the FRAUNHOFER IAPT in Hamburg. Participants will learn the theoretical basics accompanied by a comprehensive hands-on session through the complete process chain.