Thermal Powder Bed Fusion

HP and Voxeljet to challenge L-PBF

Thermal Powder Bed Fusion, also known under the brand names of Multi Jet Fusion (MJF) or High-Speed Sintering (HSS), was patented by Neil Hopkinson in 2004. This technology stands out with its productivity and high production capabilities. Thermal Powder Bed Fusion was commercialized by HP as well as VOXELJET.

Technology principle

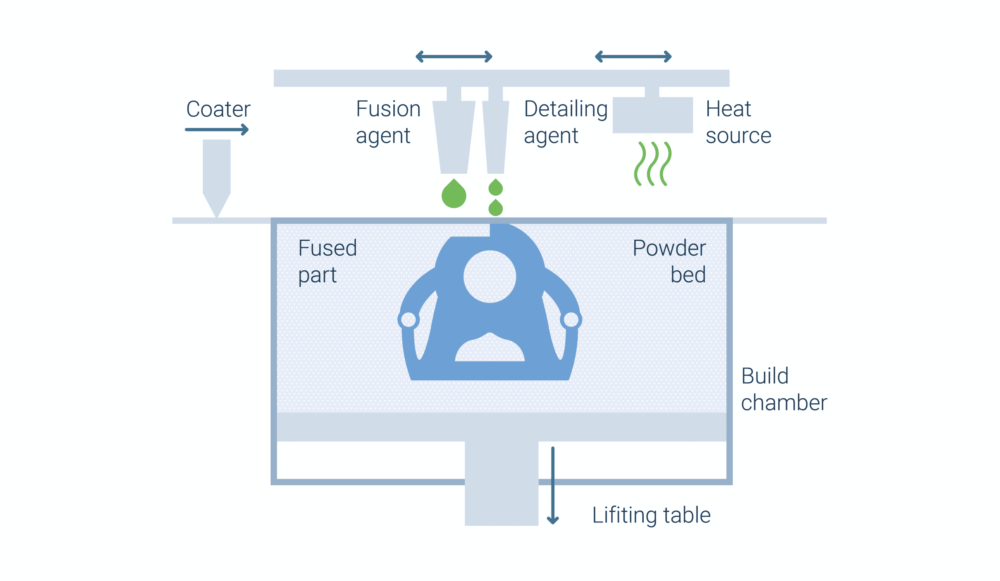

Thermal Powder Bed Fusion is a powder bed technology. The powder bed is heated evenly by infrared light. The process of solidification of the powder is initiated by the application of a fusing agent or binder. This agent is a thermally conductive liquid that is applied as small droplets by a printhead. Due to the high heat absorption of the fusion agent, the infrared light heats up the printed areas to a higher temperature which leads to the solidification of this area. This process is repeated for each layer.

A detailing agent is additionally applied to enclose the areas of the fusing agent. This isolation is used to generate sharp edges and details. It also prevents the fusing agent from diffusion in the unused powder. The combination of fusing and detailing agent leads to the high precision (about 1.200 dpi in x-y) and good surface quality of the produced parts.

Both agents are applied by a print head with a high number of nozzles. This enables the technology to scale and to create a layer with a single pass across the build chamber. This feature of the technology leads to a higher process speed compared to some other additive technologies. Another advantage of the technology is the near isotropic characteristic of the produced parts.

Read more about this topic in the Polymer Technologies Course.