Laser Powder Bed Fusion (L-PBF) – Polymer

Polymer Laser Powder Bed Fusion (L-PBF), often referred to as Selective Laser Sintering (SLS), is part of the Powder Bed Fusion family and among the most widely used polymer processes in an industrial context. L-PBF is used for the production of parts in low to medium quantities. L-PBF parts show almost isotropic properties and are thus suitable for prototypes and functional parts. Especially the development over the past years of high temperature material systems made this technology also relevant for industrial use within aviation and other high-performance industries.

Technology principle

How does Laser Powder Bed Fusion work?

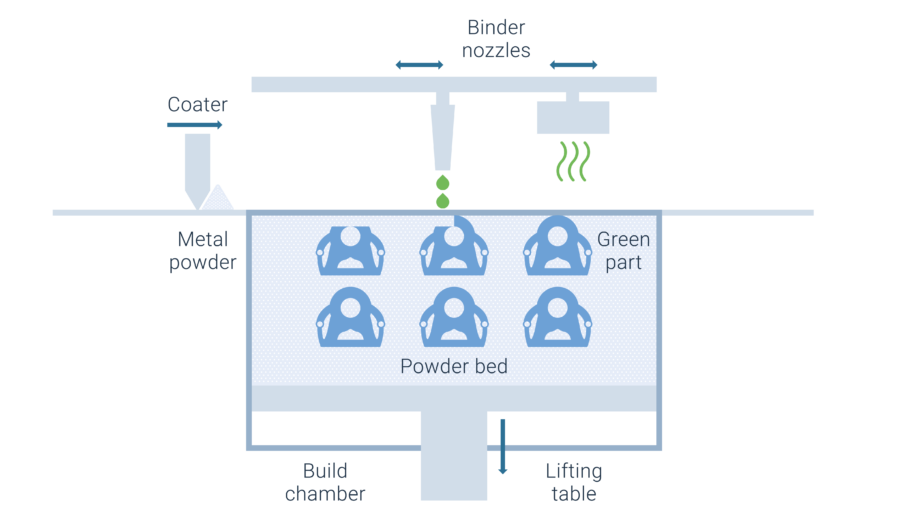

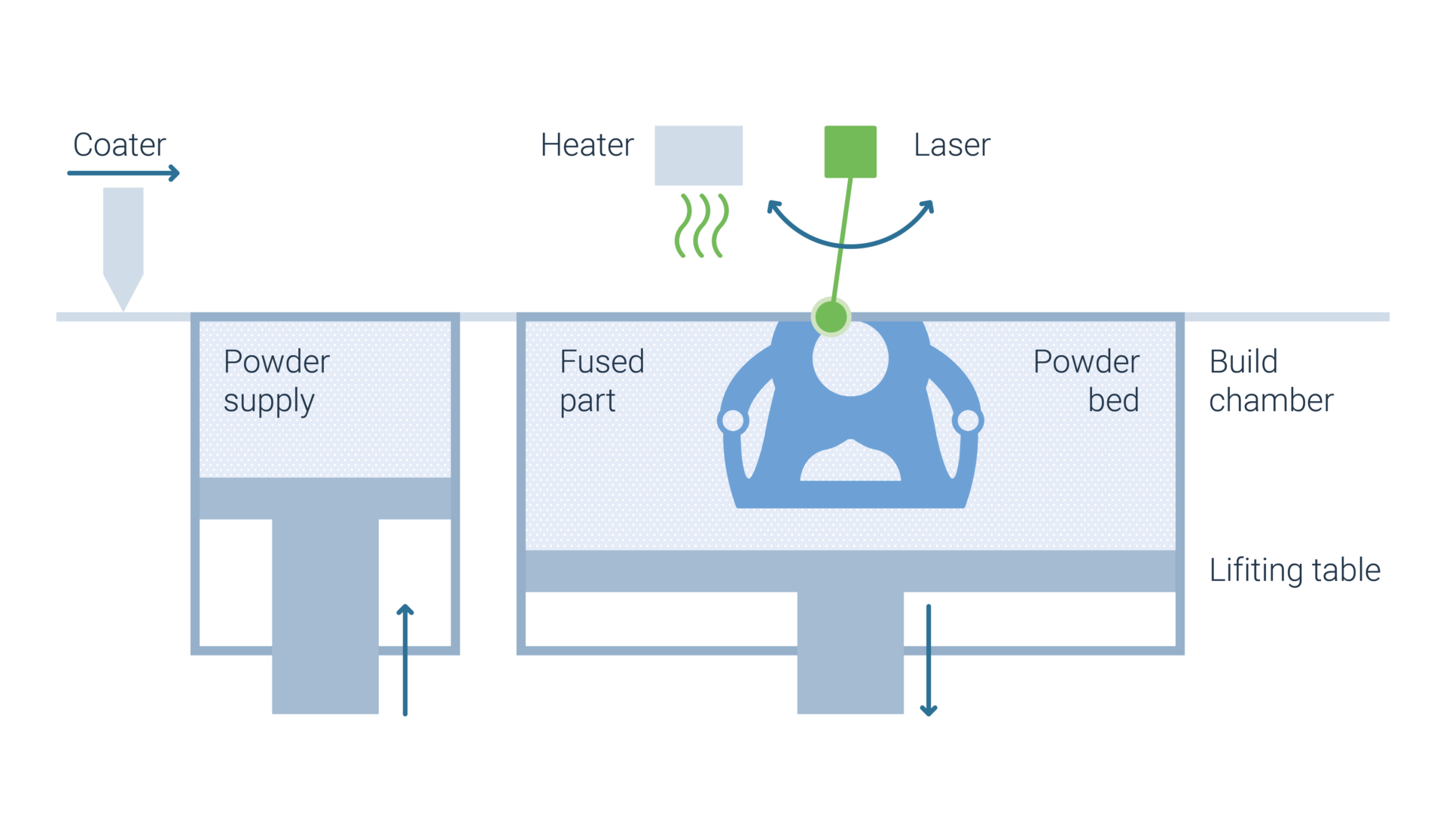

The L-PBF technology is based on thermoplastic polymer powder feedstock. The leveling system is defining the layer thickness by lowering the complete build box by the predefined layer thickness. The powder is than applied on the base plate by either a blade or roller recoating system, depending on the vendor.

The generated layer is pre-heated by infrared light to near melting temperature. A laser beam, usually a CO2-laser, guided by a XY-galvo scanning unit is heating the powder to full melting temperature. The laser moves across the powder bed to selectively melt the x-y-contour of the layer. Afterwards, the platform is lowered again by the layer thickness and the next powder feedstock layer is applied. This cyclically procedure additively manufactures the component layer by layer. When exposing the next layer, it fuses with the previously generated layer. The process described is repeated until the entire component geometry is generated. The unexposed powder remains loose and most of it can be recycled.

After the last layer is completed the entire component is taken out of the build chamber. Due to the high build chamber temperature, the unexposed powder forms a relatively firm “powder cake”. The excess powder is to be removed in the following process by compressed air or brushes to unveil the component. Powder closest to the parts cannot be recycled due to aging caused by the high temperature level. Additional postprocesses to improve the surface quality or coloring may be carried out.

Read more about this topic in the Polymer Technologies Course.