The power of 3D Printing and automated design for jigs & fixtures

AMPOWER Academy 3D Printing and automated design for jigs & fixtures Trinckle, Audi Sport, Deutsche Bahn Tooling, jigs & fixtures

Innovative Approach, Internal Collaboration, and Supplier Selection Propel the World’s Leading Packaging Machine Manufacturer Towards 3D Printing Success.

BOBST Mex SA is one of the world’s leading suppliers of substrate processing, printing and converting equipment and services for the label, flexible packaging, folding carton and corrugated board industries. Founded in 1890 by Joseph Bobst in Lausanne, Switzerland, BOBST has a presence in more than 50 countries, runs 19 production facilities in 11 countries and employs more than 5 800 people around the world.

“Leading innovation” is one of the main strategic goals for BOBST. As a leader in innovation BOBST is constantly adopting new technologies. 3D Printing became one of those technologies when the company took a strategic approach to implement the technology in 2018. 3D Printing enables BOBST to increase machine efficiency and increase customer service due to individual solutions and fast spare part reaction time.

One of the many 3D Printing success stories at BOBST was a customized part for an Asian customer, who had acquired an EXPERTFOLD 110 folder-gluer machine and decided to enhance the machine’s gluing capacity with an additional tank after the delivery of the machine. The part had to be customized and traditional manufacturing would have been both complicated and delivery time would have taken too long. It was therefore decided that the part should be manufactured using 3D Printing. It took 3 weeks from decision to use 3D Printing to delivery of the part for installation on the machine.

We are efficiently building our additive manufacturing capabilities at BOBST. Innovation is at our heart and the new technologies and methods are bringing benefits to our customers, and additive manufacturing are also increasing our R&D and Supply chain capacity

Tim Lair, Additive Manufacturing Engineer at BOBST

The initiative to investigate and utilize the potential of 3D Printing came straight from the CEOs office in 2018. However, the implementation is not always as straight forward as the industry likes to suggest. A main hurdle for such a groundbreaking new technology is the design mindset of the engineering teams. BOBST is an established company with a history for extremely reliable high-end processing machines, where a new manufacturing technology is not easily accepted. Material properties and cost per part proved to be the main hurdles.

It turns out that no one can take the shortcut and simply accept external standards or supplier data sheets. To achieve internal acceptance of a manufacturing technology, no matter if polymer of metal, one has to prove that the material properties fulfil the expected values. This is not a one-time effort, but parts rather need to leave the shop floor in a constant quality. In the best case, internal use cases have to undergo a complete in-build test.

Learning 1

Users cannot take shortcuts. Prove material properties with internal use cases and testing.

3D Printing allows for new functionalities and optimized designs. One of the basic rules is that material is being deposited only where it is needed. This mindset is common for casting applications, however in a typical industrial machine company, casting is not a standard process. The mindset of most engineers is driven by machining capabilities, where material is being removed rather than added. This however means that at BOBST, engineers had to be actively learn how to design new applications bottom up, starting with the actual functionality of the application in mind. The BOBST team was successful with on-site workshops where both external and internal trainers were teaching 3D Printing fundamentals followed by a hands-on engineering workshop on specific parts. In 2022, the company did 4 of those workshops at international BOBST sites with every meeting leading to 3-4 high potential applications.

Learning 2

A new design mindset requires intensive training and open design workshops with engineers.

Acceptance is driven by communication. This is true both internally towards employees and externally towards customers. Nothing works better to spread the word about the advantages of 3D Printing than successful, proprietary use cases. The engineers at BOBST quickly realized the value that 3D Printing can bring to the company and its customers. The main tool is the intranet, where co-workers can keep track of the activities and success stories. Another important communication channel comes from our customer visits. The 3D Printing facility within BOBST is a major stop for all customers.

While BOBST invested in their own machines for metal and polymer 3D printing early on, they were continuously working with external suppliers for selected applications. The focus was was initially on suppliers delivering high-quality parts. This strong focus on quality also meant that parts came at a high price. Over the years, additional suppliers with a stronger focus on costs have been onboarded, which ultimately leads to more successful business cases. Suppliers are now selected from a bigger pool based on specific application requirements.

Learning 3

Choose the right suppliers that fulfil the required quality and price level.

3D Printing at BOBST is now a key technology to enable custom solutions at short reaction times. It took several years and even after 5 years of implementation, the full potential of 3D Printing is yet to be unlocked. At BOBST, 3 key learnings where identified that can help industrial companies to successfully implement the technology:

AMPOWER Academy 3D Printing and automated design for jigs & fixtures Trinckle, Audi Sport, Deutsche Bahn Tooling, jigs & fixtures

AMPOWER Academy 3D printing at Deutsche Bahn Deutsche Bahn Railway Berlin, Germany 26.09.2023 Share article Frankfurt (Main) Hbf – Einfahrt

AMPOWER Academy 3D printing at Eaton Aerospace Fueling progress: How Eaton Aerospace’s dedication to 3D Printing elevated aircraft performance Eaton

Would you like to further advance your 3D Printing success story? We learned that training a broad number of employees is key to increase the usage of 3D Printing in a company and to successfully launch new applications.

You can try out the AM Fundamentals course of the AMPOWER Academy free of charge

Understand the most important topics to get started with Additive Manufacturing

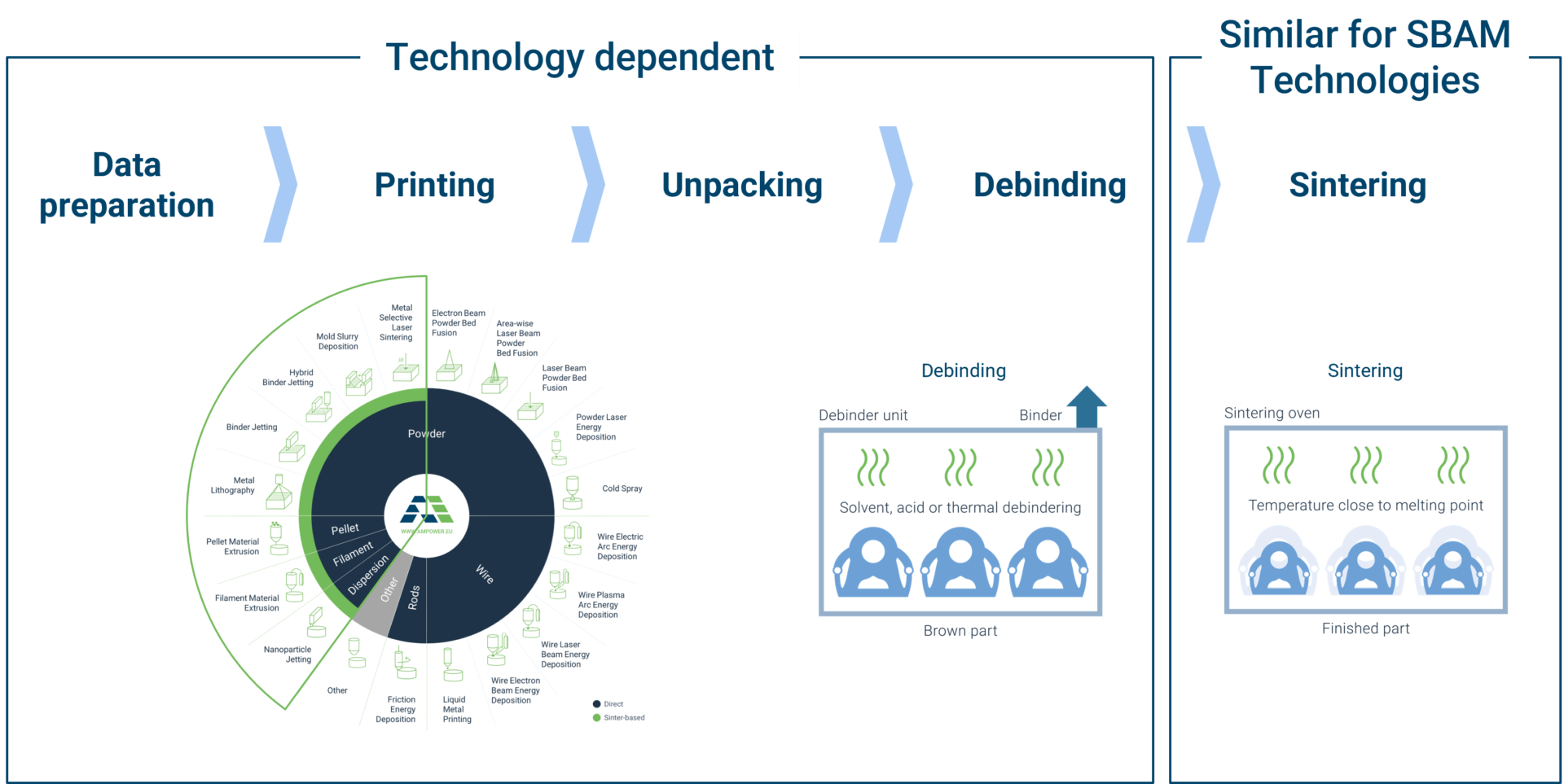

The sinter-based AM (SBAM) technologies have, as the name suggests, the sintering process in common. In this process, the printed green part is consolidated into a dense part and receives its final properties. The green part can be printed in advance using different technologies.They all have in common that metal powder is bound to the desired shape by a binder. The best-known printing technologies include Binder Jetting and Filament Material Extrusion.

In this section, you learn everything about the sinter-based AM process chain and get an overview of the different printing technologies.

This course is aimed at engineers, designers and other professionals that are working closely with sinter-based AM technologies. The goal is to cover the most important aspects that will enable engineers and designers to fully grasp the capabilities and technical limitations of the printing technologies and the sintering process to succeed in technology selection and part design. Besides going through the course from the beginning until the end, this course can also act as a constant source of knowledge while working on AM projects.

The course is structured into the following sections.

This section will start with an overview of the sinter-based AM process chain and its printing technologies, followed by a technology deep dive into the most important aspects of the BJT technology, followed by a closer look at the debinding and sintering step also including sintering simulation .

The second section will provide an overview of the different materials that are available as well as part characteristics that can be achieved with the BJT process and typical methods for quality assurance. Finally, several common defects in the BJT process are presented.

The last section will act as a guideline for designers. Besides generally describing the process when designing for Additive Manufacturing, actionable restrictions and guidelines for the BJT process are provided. The final section will present several design examples from different industries.

Simulation to compensate the deformation during the sintering step, nesting of parts and definition of printing parameters

Through various printing processes, different feedstocks such as metal powders, filaments, pellets or dispersions are processed into green parts

Unpacking of fragile green parts needs to be done carefully and is typically a manual process.

Debinding describes the process of removing the binder which results in a brown part

To reach the structural integrity of a metal part, a sinter process is required. The powder particles fuse together to a coherent, solid structure via a mass transport that occurs at the atomic scale driven via diffusional forces.

The brown part shrinks ~13-21 % in each direction.

The process chain of sinter-based technologies differs from other AM Technologies. Especially the post-printing processes (debinding and sintering) are crucial to achieve the intended mechanical properties.

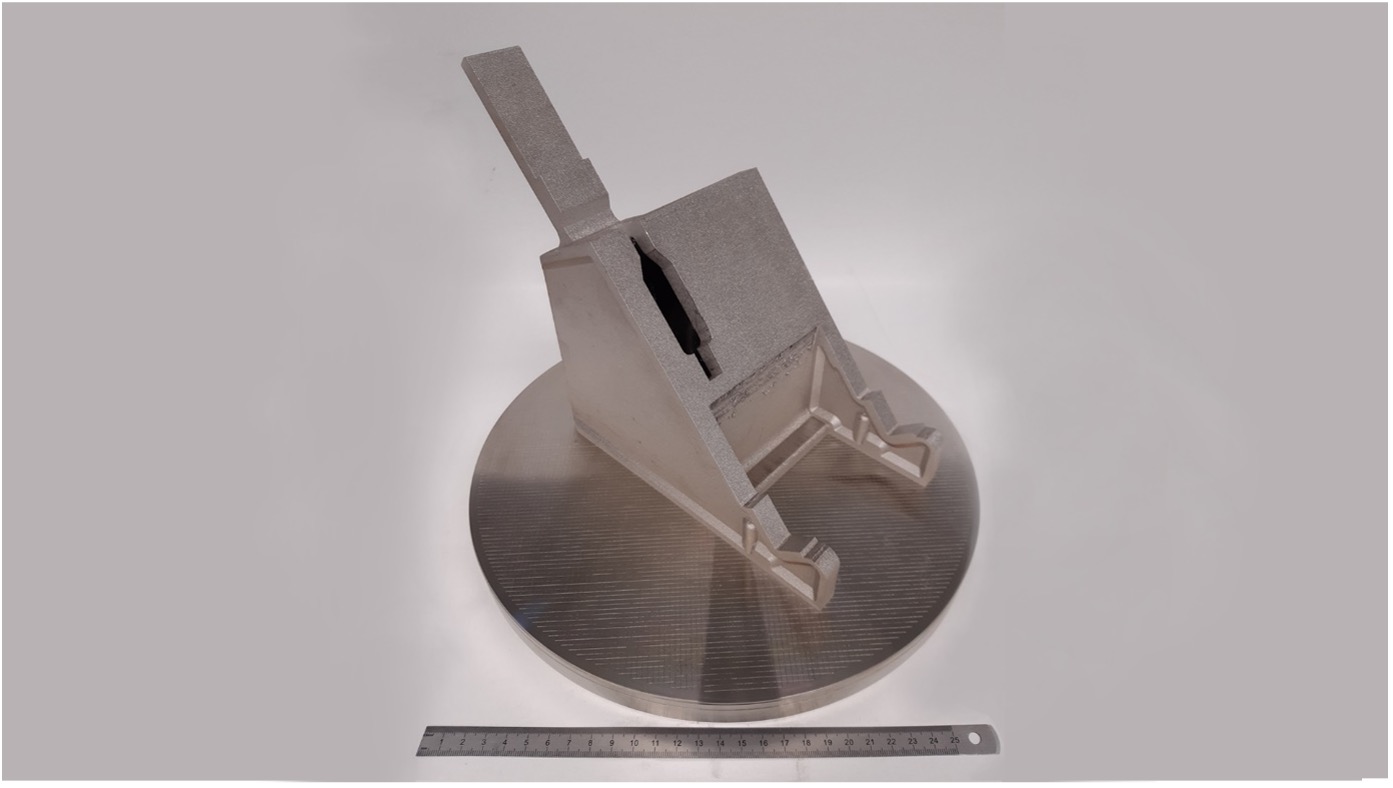

Binder Jetting is a powder based Additive Manufacturing technology in which a liquid polymer binder is selectively deposited onto the powder bed binding the metal particles and forming a green body.

The metal powder is applied to a build platform in a typical layer thickness of 40 µm to 100 µm. Subsequently a modified 2D print head apply a binder selectively onto the powder bed. Depending on machine technology a hardening or curing process of the binder is performed in parallel for each layer and/or at the end of the whole build. During the in-situ curing process a heat source is used to solidify the binder and form a solid polymer – metal powder composite.

Afterwards the build platform moves downward by the amount of one layer thickness and a new layer of powder is applied. Again, the liquid binder is deposited and hardened in the required regions of the next layer to form the green body. This process is repeated until the complete part is printed. After the complete printing process is finished the parts have to be removed from the “powder cake” meaning the surrounding loose but densified powder. To improve the removal of the excess powder from the green body often brushes or a blasting gun with air pressure are used.

To create a dense metal part the 3D printed green body has to be post-processed in a debinding and sintering process. Similar to the metal injection molding process BJT parts are placed in a high temperature furnace, where the binder is burnt out and the remaining metal particles are sintered together. The sintering results in densification of the 3D printed green body to a metal part with high densities of 97 % to 99,5%, dependent of the material.

In classic Binder Jetting systems such as the ones distributed by EXONE or DIGITAL METAL the liquid binding agent is selectively deposited with a single print head. Meaning the width of the print head does not cover the full width of the powder bed. Therefore, the print head moves multiple times in xy-direction over the powder bed to completely cover the printing area and distributing the polymer binder.

The SINGLE PASS JETTING technology was developed by DESKTOP METAL and HEWLETT PACKARD. The width of the printing head covers the full width of the powder bed. When the printhead passes over the powder bed, binder is released from more than 30,000 small nozzles and the whole powder layer is selectively immersed in binder in one pass. The process is bi-directional which means that the binder deposition takes place in both moving directions of the printhead. With these modifications the printing speed is significantly increased.

A similarly fast technology is the METAL JET process by HEWLETT PACKARD. In a single pass, a liquid printing agent is applied to the powder layer and subsequently partially evaporated to form the binding polymer around the metal powder. After the completion of the print an additional curing to achieve the full green body stability is needed.

3DEO combines the Binder Jetting process with a subsequent machining process. Different from conventional Binder Jetting processes, the binder is not only deposited selectively but onto the entire powder layer. After hardening of the complete layer, the part geometry is shaped through a milling process every couple of layers by cutting the part contour out of the binder powder composite.

Binder Jetting is a powder based Additive Manufacturing technology in which a liquid polymer binder is selectively deposited onto the powder bed binding the metal particles and forming a green body.

The metal powder is applied to a build platform in a typical layer thickness of 40 µm to 100 µm. Subsequently a modified 2D print head apply a binder selectively onto the powder bed. Depending on machine technology a hardening or curing process of the binder is performed in parallel for each layer and/or at the end of the whole build. During the in-situ curing process a heat source is used to solidify the binder and form a solid polymer – metal powder composite.

Binder Jetting is a powder based Additive Manufacturing technology in which a liquid polymer binder is selectively deposited onto the powder bed binding the metal particles and forming a green body.

The metal powder is applied to a build platform in a typical layer thickness of 40 µm to 100 µm. Subsequently a modified 2D print head apply a binder selectively onto the powder bed. Depending on machine technology a hardening or curing process of the binder is performed in parallel for each layer and/or at the end of the whole build. During the in-situ curing process a heat source is used to solidify the binder and form a solid polymer – metal powder composite.

Binder Jetting is a powder based Additive Manufacturing technology in which a liquid polymer binder is selectively deposited onto the powder bed binding the metal particles and forming a green body.

The metal powder is applied to a build platform in a typical layer thickness of 40 µm to 100 µm. Subsequently a modified 2D print head apply a binder selectively onto the powder bed. Depending on machine technology a hardening or curing process of the binder is performed in parallel for each layer and/or at the end of the whole build. During the in-situ curing process a heat source is used to solidify the binder and form a solid polymer – metal powder composite.

Binder Jetting is a powder based Additive Manufacturing technology in which a liquid polymer binder is selectively deposited onto the powder bed binding the metal particles and forming a green body.

The metal powder is applied to a build platform in a typical layer thickness of 40 µm to 100 µm. Subsequently a modified 2D print head apply a binder selectively onto the powder bed. Depending on machine technology a hardening or curing process of the binder is performed in parallel for each layer and/or at the end of the whole build. During the in-situ curing process a heat source is used to solidify the binder and form a solid polymer – metal powder composite.